SKY F

11

EN

cod. 3540Z105 - Rev. 01 - 01/2018

3.3 Plumbing connections

Important

B

Before making the connection, check that the unit is arranged for operation with

the type of fuel available and carefully clean all the system pipes.

Carry out the relevant connections according to the cover diagram and the symbols giv-

en on the unit .

System water characteristics

In the presence of water harder than 25° Fr (1°F = 10ppm CaCO

3

), use suitably treated

water in order to avoid possible scaling in the water heater.

3.4 Gas connection

The gas must be connected to the respective union (see figure on cover) in conformity

with the current regulations, with a rigid metal pipe or with a continuous flexible s/steel

tube, installing a gas cock between the system and water heater . Make sure all the gas

connections are tight.

3.5 Electrical connections

Important

B

BEFORE CARRYING OUT ANY OPERATION THAT REQUIRES REMOVING

THE CASING, DISCONNECT THE BOILER FROM THE ELECTRIC MAINS

WITH THE MAIN SWITCH.

NEVER TOUCH THE ELECTRICAL COMPONENTS OR CONTACTS WITH

THE MAIN SWITCH TURNED ON! THERE IS A DANGER OF ELECTRIC

SHOCK WITH THE RISK OF INJURY OR DEATH!

B

The unit must be connected to an efficient grounding system in accordance with

current safety regulations. Have the efficiency and suitability of the grounding

system checked by professionally qualified personnel; the Manufacturer de-

clines any liability for damage caused by failure to ground the system.

The water heater is prewired and has a "Y" type cable (without plug) for con-

nection to the electric line. The connections to the grid must be made with a per-

manent connection and equipped with a double-pole switch with contact gap of

at least 3 mm, interposing fuses of max. 3A between the water heater and the

line. Make sure to respect the polarities (LINE: brown wire / NEUTRAL: blue

wire / GROUND: yellow-green wire) in the connections to the electric line.

B

The unit's supply cable

MUST NOT BE REPLACED BY THE USER

.

If the ca-

ble gets damaged, turn the unit off and have the cable replaced only by

professionally qualified personnel.

In case of replacement, only use cable

“HAR H05 VV-F”

3x0.75 mm2 with max. external diameter of 8 mm.

3.6 Fume ducts

B

THE BOILER MUST BE INSTALLED IN PLACES THAT MEET THE FUNDA-

MENTAL REQUIREMENTS FOR VENTILATION. OTHERWISE THERE IS A

DANGER OF SUFFOCATION OR INTOXICATION.

READ THE INSTALLATION AND MAINTENANCE INSTRUCTIONS BE-

FORE INSTALLING THE UNIT.

ALSO FOLLOW THE DESIGN INSTRUCTIONS

.

Important

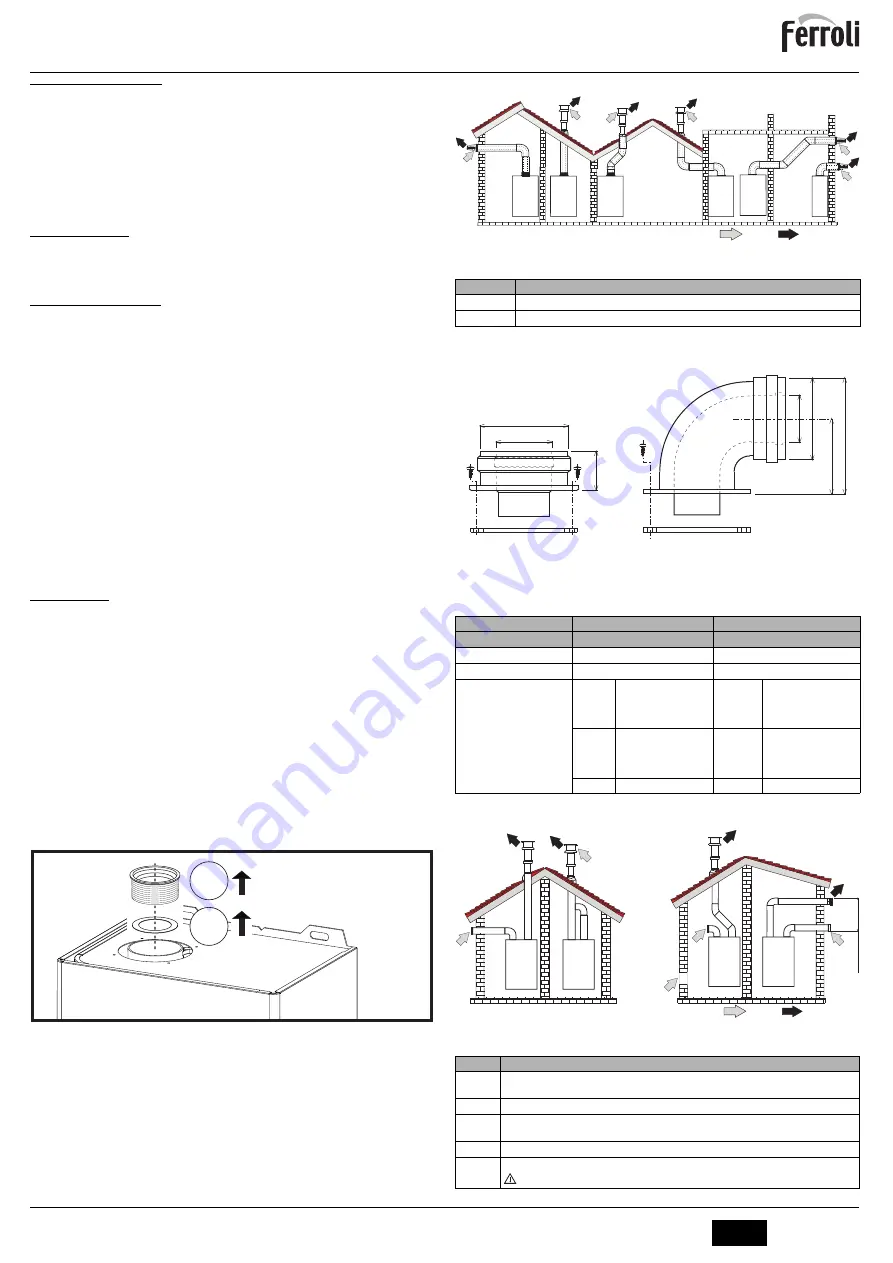

The unit is a "C type" with sealed chamber and forced draught, the air inlet and fume out-

let must be connected to one of the following extraction/suction systems. The unit is ap-

proved for operation with all the

Cny

flue configurations given on the dataplate. Some

configurations may be expressly limited or not permitted by law, standards or local reg-

ulations. Before installation, check and carefully follow the instructions. Also, comply with

the instructions on the positioning of wall and/or roof terminals and the minimum distanc-

es from windows, walls, ventilation openings, etc.

Baffles

Unit operation requires fitting the baffles supplied. Make sure the right baffle (when used)

is fitted and correctly positioned.

A

Baffle replacement with

unit not installed

Connection with coaxial pipes

fig. 5 - Examples of connection with coaxial pipes (

= Air /

= Fumes)

Table. 1 - Typology

For coaxial connection, fit the unit with one of the following starting accessories. For the

wall hole dimensions, refer to the figure on the cover.

fig. 6 - Starting accessory for coaxial ducts

Table. 2- Baffles for coaxial ducts

Connection with separate pipes

fig. 7 - Examples of connection with separate pipes (

= Air /

= Fumes)

Table. 3 - Typology

A

1

2

Type

Description

C1X

Wall horizontal exhaust and inlet

C3X

Roof vertical exhaust and inlet

Coaxial 60/100

Coaxial 80/125

Max. permissible length

4 m

10 m

Reduction factor 90° bend

1 m

0.5 m

Reduction factor 45° bend

0.5 m

0.25 m

Baffle to use

0 ÷ 2 m

Model

SKY F 11

= Ø43

SKY F 14

= Ø47

SKY F 17

= Ø47

0 ÷ 3 m

Model

SKY F 11

= Ø39

SKY F 14

= Ø47

SKY F 17

= Ø47

2 ÷ 3 m

Model

SKY F 11

= Ø43

SKY F 14

= Ø50

SKY F 17

= Ø50

3 ÷ 6 m

Model

SKY F 11

= Ø43

SKY F 14

= Ø50

SKY F 17

= Ø50

3 ÷ 4 m

NO BAFFLE

6 ÷ 10 m

NO BAFFLE

Type

Description

C1X

Wall horizontal exhaust and intake. The inlet/outlet terminals must be concentric or close enough to be

undergo similar wind conditions (within 50 cm)

C3X

Roof vertical exhaust and intake. Inlet/outlet terminals like for C12

C5X

Wall or roof exhaust and intake separate or in any case in areas with different pressures. The exhaust

and intake must not be positioned on opposite walls.

C6X

Intake and exhaust with separately certified pipes (EN 1856/1)

B2X

Intake from installation room and wall or roof exhaust

IMPORTANT - THE ROOM MUST BE PROVIDED WITH APPROPRIATE VENTILATION

C

1X

C

1X

C

3X

C

3X

C

3X

C

1X

010006X0

010007X0

68

11

8

100

60

45.6

100

60

C

5x

C

3x

B

2x

C

1x

max 50 cm

Summary of Contents for SKY 11 F

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ... DEEULFDWR LQ WDOLD 0DGH LQ WDO 552 6 S Via 5LWRQGD D 6DQ RQLIDFLR 9HURQD 7 ZZZ IHUUROL FRP ...