If the following conditions have been met:

1) the initial check cycle period for the instrument panel warning lights has elapsed;

2) engine speed has exceeded and remained above 700 rpm for at least 3 seconds;

3) the check cycle has been completed successfully (no failures);

4) the Service information has been displayed for five seconds.

The message “

Check OK

” is displayed against a green background in area D.

If only conditions 1, 3 and 4 have been met (engine not started), the main screen memorised previously

(even following a Key-off/Key-on cycle) is displayed immediately (without the “Check OK” message).

The “Check OK” message will be displayed as soon as condition 2 is met, provided that the other conditions

persist.

After the initial check cycle period for the instrument panel warning lights, the instrument panel waits a further

1000 ms before indicating any failures (with the exception of the warnings: “Minimum engine oil”

and/or “Inertia switch triggered” and/or “Electronically controlled gearbox safety warnings” and/or “EPB

disengaged” and/or “Parking brake on”, which are displayed as soon as they are available) or until

the “Check OK” message to ensure that all warning light checks requested by the external ECUs have

been completed (within the warning light check display period).

During the diagnostic cycle (“Check in progress” screen displayed), should any of the following events

occur: “Low engine oil pressure” and/or “Inertia switch triggered” and/or “Electronically controlled gearbox

safety warnings” and/or “EPB disengaged” and/or “Parking brake on”, the relative event is displayed

immediately (without interrupting the “Check in progress” screen), whereas, in the event of all other faults

(priority 0, 1 or 2), the fault is displayed only after the "Check in progress" screen display period has

elapsed.

In these cases, the display logic for diagnostic cycle progress is overridden and, once the fault display cycle

is complete, the standard screen or the currently active screen is displayed.

Safety messages relative to the electronically controlled gearbox are as follows:

depress brake pedal;

depress brake pedal and engage gear;

depress brake pedal and press PS to engage gear;

set gearbox lever to neutral;

delayed ignition;

reduce gear changes;

manual method unavailable;

automatic method unavailable;

gearbox not in Parking position;

carwash mode activation;

only manual unlock gearbox allowed: See manual.

Summary of Contents for California

Page 19: ...Z Tyre type and pressure label ...

Page 20: ...04 02 Assembly number Assembly number A Assembly number label ...

Page 21: ...04 03 Chassis number Chassis number B Punched chassis number ...

Page 22: ...04 04 Engine type and number Engine type and number C Punched engine type and number ...

Page 23: ...04 05 Chassis number Chassis number D Chassis number ...

Page 24: ...04 06 Gearbox type and number Gearbox type and number E Gearbox type and number plate ...

Page 25: ...04 07 Vehicle identification Vehicle identification K VIN label Vehicle Identification Number ...

Page 28: ...04 10 Fuel Fuel I Fuel label ...

Page 29: ...04 11 Paintwork Paintwork L Paintwork label ...

Page 30: ...04 12 Emissions control Emissions control M Emissions control data label ...

Page 31: ...04 13 Airbag Airbag N Do not install child seat on passenger seat label ...

Page 32: ...04 14 Airbag Airbag O Airbag maintenance label ...

Page 33: ...04 15 Airbag Airbag P Airbag warning label ...

Page 43: ...Fluids and lubricants table Model Fluids and lubricants table Download ...

Page 71: ...Screw the cap A back on tightly ...

Page 104: ...Connect the battery F2 01 ...

Page 118: ...Vehicle Setup Parameter Check Form Model Vehicle Setup Parameter Check Form Download ...

Page 520: ...A DCT gearbox clutch oil tank and clutch oil pump B Clutch oil pipes C Clutch oil radiator ...

Page 623: ...CCM Brake Disc Wear Form Model All Models CCM Brake Disc Wear Form Download ...

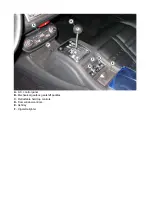

Page 1070: ...A Horn button B Engine start button C Manettino ...

Page 1102: ...Perform the respective cycle with the DEIS diagnostic tester ...

Page 1144: ...Connect the battery F2 01 ...

Page 1220: ...Precautions and guidelines for using the RHT retractable hard top ...

Page 1334: ...Undo the indicated fasteners Retrieve the indicated shims Release the clip 1 ...

Page 1335: ...Remove the indicated clip Undo the indicated screw Undo the screws indicated ...

Page 1452: ...Refit the rear wheelhouses E3 05 Connect the battery F2 01 ...

Page 1453: ...F2 07 Lights Diagnosing condensation in headlamps ...

Page 1561: ...Ss Sensor signal λ Lambda ratio excess g Rich mixture M Lean mixture ...

Page 1570: ...Refit the DCT gearbox C2 03 Connect the battery F2 01 ...

Page 1656: ...G Heater evaporator H Pollen filter I Air vents M Expansion valve ...

Page 1677: ...Refit the front wheelhouses E3 05 ...

Page 1686: ...Refit the caps 1 Refit the engine compartment cosmetic shields E3 13 ...