E7.01 Sanding and cleaning

Pre-Cleaning

Steel. Remove rust by sandblasting, wire brush or coarse sanding paper (P16 to P80) to

achieve a bare substrate. For rust through areas tinning is recommended. In case of larger

damaged areas it might be necessary to weld in a new sheet or to replace the whole part.

Remove any remains like scale from welding, tinning or any parting compounds and fluxing

agents thoroughly.

Cleaning

Clean any old paint (OE finish) thoroughly with water first to remove any water soluble dirt.

Clean with a suitable pre-cleaner, e.g.

D837 DX330 Spirit Wipe

o

D845 DX310 High

Strength Degreaser

. If there is any VOC legislation in force, use

D842 DX380 low VOC

Cleaner

or

D8401 Waterborne low VOC Cleaner

. If using

D842

, rinse the surface with

T494

Envirobase thinner

immediately after degreasing, then dry the panel surface.

Dry Sanding (rotary-orbital machine)

Use the following paper grades depending on the substrate. Start with the coarsest grade and

carry on down to the finest grade. Fleeces and pads are especially recommended for edges

and borders. Use a guide coat for best results:

TM

™ red pad, 3M Soft Pad ultrafine

TM ™

grey pad, 3M Soft Pad ultrafine

Tinned Steel P80-P220

TM

™ red pad, 3M Soft Pad ultrafine

E-Coat (spare

parts)

P280 - P400, 3M Scotch-Brite ™ grey pad, 3

M Soft Pad ultrafine (faultless E-Coat requires

only cleaning)

OE Finish / Repair

Coatings

P240 - P400, 3M Scotch-Brite ™ red pad, 3M

Soft Pad superfine

Putty / Filler

Coarse sanding: P80 - P150, fine sanding:

P240 - P320

Spray Polyester

Coarse sanding: P150, fine sanding: P240 -

P320

Primer

P320 - P400, 3M Soft Pad ultrafine

Surfacer

P320 - P400, 3M Soft Pad ultrafine

Topcoat (blending

areas)

P800 - P1500, 3M Soft Pad ultrafine, 3M

Scotch-Brite ™ pad superfine

Clearcoat (blending

areas)

P800 - P1500, 3M Soft Pad ultrafine, 3M

Scotch-Brite ™ pad superfine

Dry Sanding (rotary-orbital machine)

Use the following paper grades depending on the substrate. Start with the coarsest grade and

carry on down to the finest grade. Fleeces and pads are especially recommended for edges

and borders:

E-Coat (spare parts)

P600 - P800, 3M Soft Pad ultrafine

(faultless E-Coat requires only cleaning)

OE Finish / Repair

Coatings

P320 - P400, 3M Soft Pad ultrafine

Putty / Filler

NEVER USE

wet sanding for putties!

Spray Polyester

NEVER USE

wet sanding for putties!

Primer

P320 - P400, 3M Soft Pad ultrafine

Surfacer

P320 - P400, 3M Soft Pad ultrafine

Topcoat (blending

areas)

P320 - P400, 3M Soft Pad ultrafine

Summary of Contents for California

Page 19: ...Z Tyre type and pressure label ...

Page 20: ...04 02 Assembly number Assembly number A Assembly number label ...

Page 21: ...04 03 Chassis number Chassis number B Punched chassis number ...

Page 22: ...04 04 Engine type and number Engine type and number C Punched engine type and number ...

Page 23: ...04 05 Chassis number Chassis number D Chassis number ...

Page 24: ...04 06 Gearbox type and number Gearbox type and number E Gearbox type and number plate ...

Page 25: ...04 07 Vehicle identification Vehicle identification K VIN label Vehicle Identification Number ...

Page 28: ...04 10 Fuel Fuel I Fuel label ...

Page 29: ...04 11 Paintwork Paintwork L Paintwork label ...

Page 30: ...04 12 Emissions control Emissions control M Emissions control data label ...

Page 31: ...04 13 Airbag Airbag N Do not install child seat on passenger seat label ...

Page 32: ...04 14 Airbag Airbag O Airbag maintenance label ...

Page 33: ...04 15 Airbag Airbag P Airbag warning label ...

Page 43: ...Fluids and lubricants table Model Fluids and lubricants table Download ...

Page 71: ...Screw the cap A back on tightly ...

Page 104: ...Connect the battery F2 01 ...

Page 118: ...Vehicle Setup Parameter Check Form Model Vehicle Setup Parameter Check Form Download ...

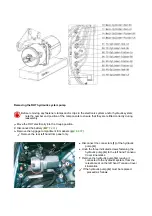

Page 520: ...A DCT gearbox clutch oil tank and clutch oil pump B Clutch oil pipes C Clutch oil radiator ...

Page 623: ...CCM Brake Disc Wear Form Model All Models CCM Brake Disc Wear Form Download ...

Page 1070: ...A Horn button B Engine start button C Manettino ...

Page 1102: ...Perform the respective cycle with the DEIS diagnostic tester ...

Page 1144: ...Connect the battery F2 01 ...

Page 1220: ...Precautions and guidelines for using the RHT retractable hard top ...

Page 1334: ...Undo the indicated fasteners Retrieve the indicated shims Release the clip 1 ...

Page 1335: ...Remove the indicated clip Undo the indicated screw Undo the screws indicated ...

Page 1452: ...Refit the rear wheelhouses E3 05 Connect the battery F2 01 ...

Page 1453: ...F2 07 Lights Diagnosing condensation in headlamps ...

Page 1561: ...Ss Sensor signal λ Lambda ratio excess g Rich mixture M Lean mixture ...

Page 1570: ...Refit the DCT gearbox C2 03 Connect the battery F2 01 ...

Page 1656: ...G Heater evaporator H Pollen filter I Air vents M Expansion valve ...

Page 1677: ...Refit the front wheelhouses E3 05 ...

Page 1686: ...Refit the caps 1 Refit the engine compartment cosmetic shields E3 13 ...