Refitting the rollbar

Fastening bracket - RHT assembly

Screw

23 Nm

B

Fastening RHT assembly bracket - rollbar

Screw

23 Nm

B

Fastening belt retractor bracket - rollbar

Screw

23 Nm

B

Fastening rear seat belt guide

Screw

4 Nm

C

Fastening the backrest lock

Screw

12 Nm

B

Tightening torque

Nm

Class

CAUTION

Pyrotechnically triggered pressurised system. Non-repairable system. Injury hazard in the event of

accidental activation! Before starting any work, ensure that the battery is disconnected! Service able only

by authorised personnel.

CAUTION

Do not lean over or rest your hands or limbs on the rollbar!

Do not place any objects on the rollbar!

The rollbar must always be replaced if it has been deployed.

A damaged or defective rollbar module must be replaced and MUST NOT be repaired.

NEVER modify the rollbar module.

The rollbar module is subject to wear and ageing and must therefore be replaced at the intervals

specified in the “Warranty Card”, EVEN if the vehicle has NOT been involved in an accident.

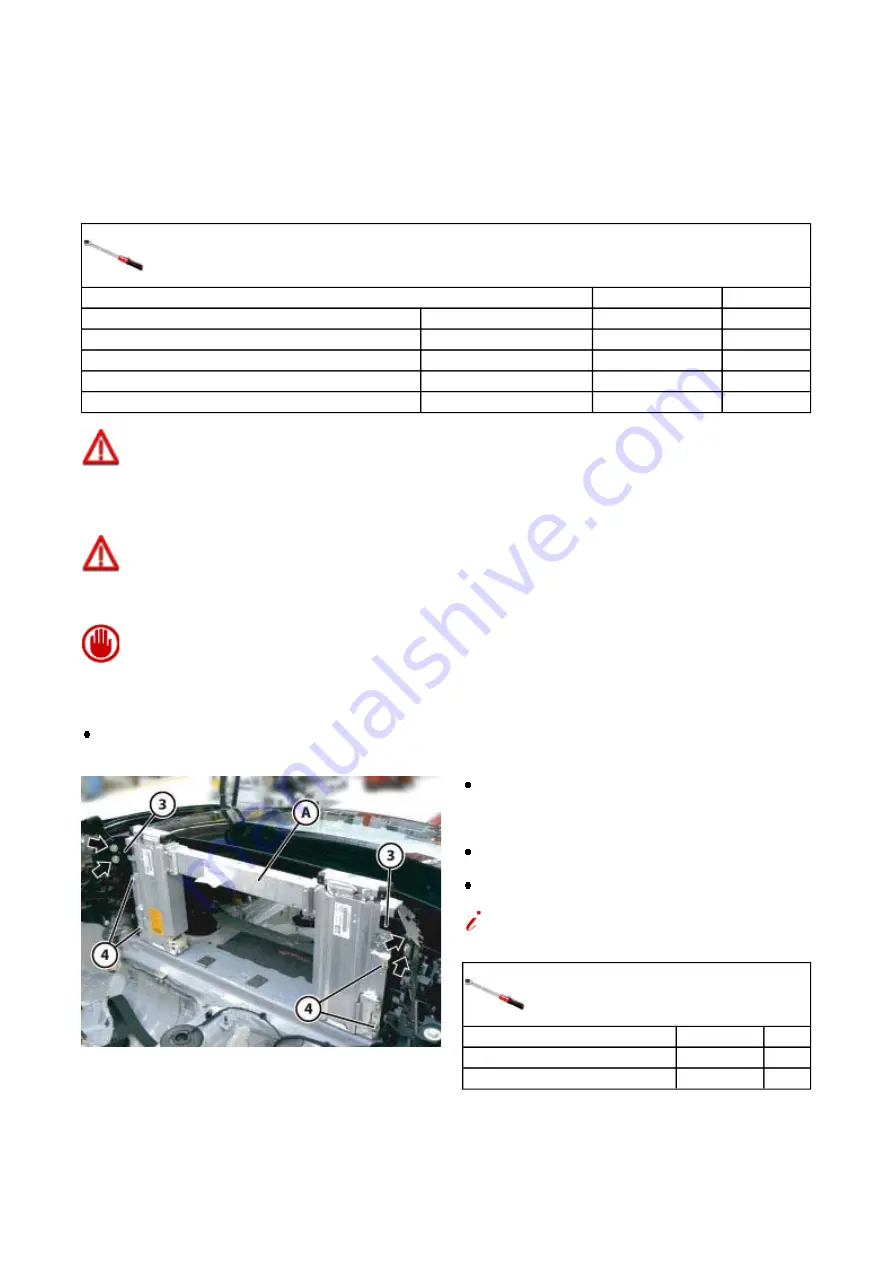

With the Front and Rear Roof shells in the luggage compartment and the Tonneau Cover open, fit the

rollbar in the relative seat on the vehicle.

Fasten the mounting brackets

(3)

to the RHT

assembly, by hand tightening the four screws

indicated, aligning the fastener hole on the

bracket with the hole on the rollbar.

Apply and hand tighten the screws

(4)

fastening

the RHT assembly to the rollbar.

Tighten the four screws indicated and the screws

(4)

.

The rollbar must remain above the bodyshell

with a gap of a few mm in between.

Tightening torque

Nm

Class

Screw 23

Nm

B

Screw 23

Nm

B

Summary of Contents for California

Page 19: ...Z Tyre type and pressure label ...

Page 20: ...04 02 Assembly number Assembly number A Assembly number label ...

Page 21: ...04 03 Chassis number Chassis number B Punched chassis number ...

Page 22: ...04 04 Engine type and number Engine type and number C Punched engine type and number ...

Page 23: ...04 05 Chassis number Chassis number D Chassis number ...

Page 24: ...04 06 Gearbox type and number Gearbox type and number E Gearbox type and number plate ...

Page 25: ...04 07 Vehicle identification Vehicle identification K VIN label Vehicle Identification Number ...

Page 28: ...04 10 Fuel Fuel I Fuel label ...

Page 29: ...04 11 Paintwork Paintwork L Paintwork label ...

Page 30: ...04 12 Emissions control Emissions control M Emissions control data label ...

Page 31: ...04 13 Airbag Airbag N Do not install child seat on passenger seat label ...

Page 32: ...04 14 Airbag Airbag O Airbag maintenance label ...

Page 33: ...04 15 Airbag Airbag P Airbag warning label ...

Page 43: ...Fluids and lubricants table Model Fluids and lubricants table Download ...

Page 71: ...Screw the cap A back on tightly ...

Page 104: ...Connect the battery F2 01 ...

Page 118: ...Vehicle Setup Parameter Check Form Model Vehicle Setup Parameter Check Form Download ...

Page 520: ...A DCT gearbox clutch oil tank and clutch oil pump B Clutch oil pipes C Clutch oil radiator ...

Page 623: ...CCM Brake Disc Wear Form Model All Models CCM Brake Disc Wear Form Download ...

Page 1070: ...A Horn button B Engine start button C Manettino ...

Page 1102: ...Perform the respective cycle with the DEIS diagnostic tester ...

Page 1144: ...Connect the battery F2 01 ...

Page 1220: ...Precautions and guidelines for using the RHT retractable hard top ...

Page 1334: ...Undo the indicated fasteners Retrieve the indicated shims Release the clip 1 ...

Page 1335: ...Remove the indicated clip Undo the indicated screw Undo the screws indicated ...

Page 1452: ...Refit the rear wheelhouses E3 05 Connect the battery F2 01 ...

Page 1453: ...F2 07 Lights Diagnosing condensation in headlamps ...

Page 1561: ...Ss Sensor signal λ Lambda ratio excess g Rich mixture M Lean mixture ...

Page 1570: ...Refit the DCT gearbox C2 03 Connect the battery F2 01 ...

Page 1656: ...G Heater evaporator H Pollen filter I Air vents M Expansion valve ...

Page 1677: ...Refit the front wheelhouses E3 05 ...

Page 1686: ...Refit the caps 1 Refit the engine compartment cosmetic shields E3 13 ...