Replace all connecting rod fastener screws

that have been subjected to operating

temperature.

After fitting, the new connecting rod fastener

screws may be removed and refitted

once only.

A connecting rod must be replaced if, after

two consecutive tightening sequences,

the control torque and/or extension

values are no longer within specified

tolerances.

A connecting rod must be replaced if the

maximum control torque value exceeds

100 Nm

The same connecting rod may be installed

up to 10 times provided that all the

tightening torque values remain within

specified tolerances.

Check the condition and cleanliness of the

mating surfaces between the connecting rod

shanks and the big end caps

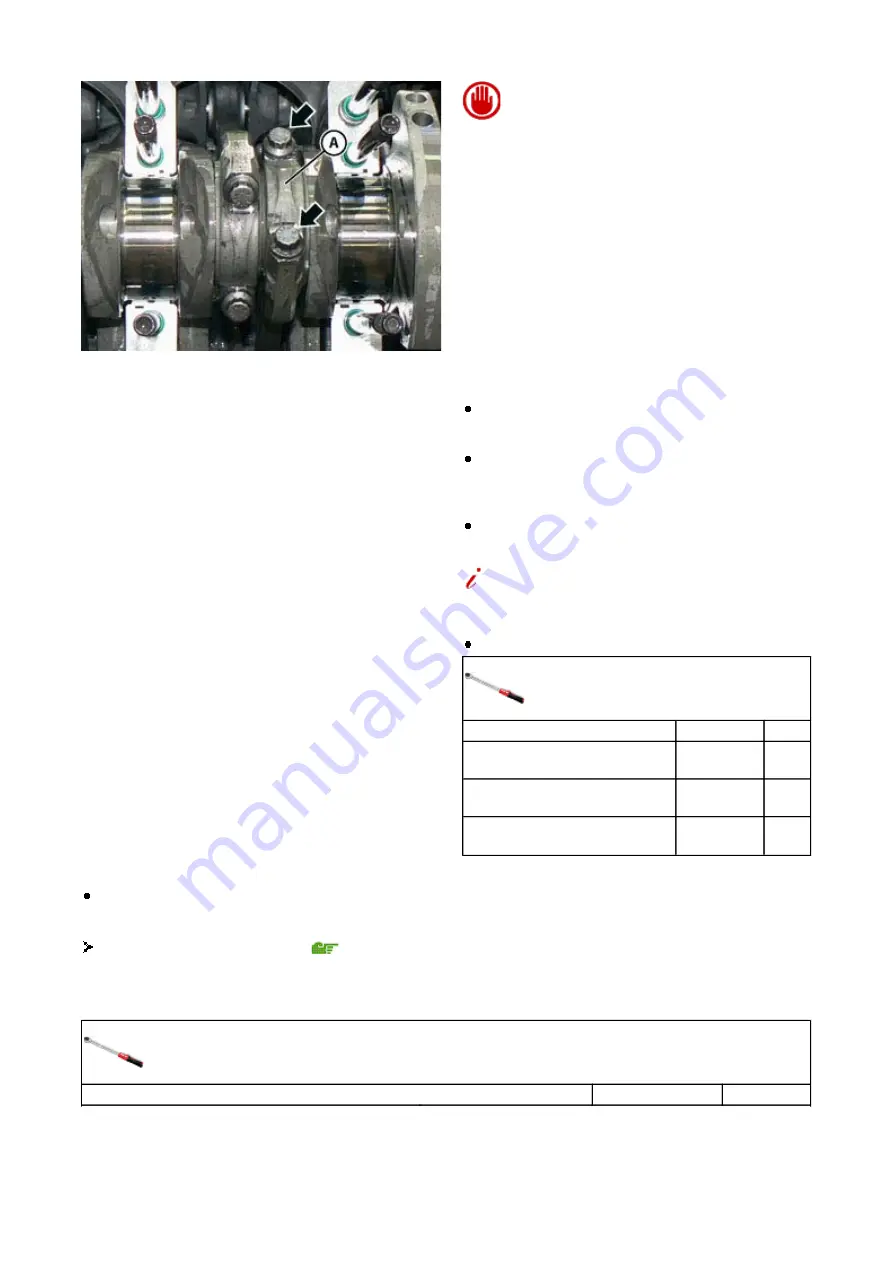

Lubricate the areas of the crankshaft

corresponding to the connecting rod caps

(A)

with engine oil

SHELL Helix Ultra SAE 5W-

40

.

Match the connecting rod caps

(A)

with the

respective connecting stems and fasten by

hand-tightening the indicated screws.

To match the components correctly, refer to the

alphanumeric code stamped on the

connecting rod caps and stems themselves.

Definitively tighten the indicated screws.

Tightening torque

Nm

Class

Screw (1st pre-tightening

stage)

20

Nm

+1.5

-1.5

0

Screw (2nd pre-tightening

stage)

30

Nm

+1.5

-1.5

0

Screw (applying angle of 58°

±

1°)

70

Nm

+15

-15

0

Using suitable feeler gauges, check that the endfloat of the connecting rods is between

0.200 and 0.339

mm

.

Refit the lower crankcase shell (

B2.05

).

Refitting the lower crankcase shell

Tightening torque

Nm

Class

Summary of Contents for California

Page 19: ...Z Tyre type and pressure label ...

Page 20: ...04 02 Assembly number Assembly number A Assembly number label ...

Page 21: ...04 03 Chassis number Chassis number B Punched chassis number ...

Page 22: ...04 04 Engine type and number Engine type and number C Punched engine type and number ...

Page 23: ...04 05 Chassis number Chassis number D Chassis number ...

Page 24: ...04 06 Gearbox type and number Gearbox type and number E Gearbox type and number plate ...

Page 25: ...04 07 Vehicle identification Vehicle identification K VIN label Vehicle Identification Number ...

Page 28: ...04 10 Fuel Fuel I Fuel label ...

Page 29: ...04 11 Paintwork Paintwork L Paintwork label ...

Page 30: ...04 12 Emissions control Emissions control M Emissions control data label ...

Page 31: ...04 13 Airbag Airbag N Do not install child seat on passenger seat label ...

Page 32: ...04 14 Airbag Airbag O Airbag maintenance label ...

Page 33: ...04 15 Airbag Airbag P Airbag warning label ...

Page 43: ...Fluids and lubricants table Model Fluids and lubricants table Download ...

Page 71: ...Screw the cap A back on tightly ...

Page 104: ...Connect the battery F2 01 ...

Page 118: ...Vehicle Setup Parameter Check Form Model Vehicle Setup Parameter Check Form Download ...

Page 520: ...A DCT gearbox clutch oil tank and clutch oil pump B Clutch oil pipes C Clutch oil radiator ...

Page 623: ...CCM Brake Disc Wear Form Model All Models CCM Brake Disc Wear Form Download ...

Page 1070: ...A Horn button B Engine start button C Manettino ...

Page 1102: ...Perform the respective cycle with the DEIS diagnostic tester ...

Page 1144: ...Connect the battery F2 01 ...

Page 1220: ...Precautions and guidelines for using the RHT retractable hard top ...

Page 1334: ...Undo the indicated fasteners Retrieve the indicated shims Release the clip 1 ...

Page 1335: ...Remove the indicated clip Undo the indicated screw Undo the screws indicated ...

Page 1452: ...Refit the rear wheelhouses E3 05 Connect the battery F2 01 ...

Page 1453: ...F2 07 Lights Diagnosing condensation in headlamps ...

Page 1561: ...Ss Sensor signal λ Lambda ratio excess g Rich mixture M Lean mixture ...

Page 1570: ...Refit the DCT gearbox C2 03 Connect the battery F2 01 ...

Page 1656: ...G Heater evaporator H Pollen filter I Air vents M Expansion valve ...

Page 1677: ...Refit the front wheelhouses E3 05 ...

Page 1686: ...Refit the caps 1 Refit the engine compartment cosmetic shields E3 13 ...