14)

Start the engine and run at idle speed for approximately

1 minute

.

15)

Bring the engine speed to

2000 rpm

for approximately

15 seconds

, then allow the engine to return to

idle speed.

16)

If necessary, top up to the

MIN

level indicated on the expansion tank.

17)

Warm the engine up by running at

2000 rpm

until the thermostat valve opens/cooling fans activate

(water temperature approx.

90°C

), then allow the engine to return to idle speed.

18)

Top up if necessary.

19)

Open the heater circuit (TGK valve_1 open and idle speed pump running) by setting the maximum

temperature for one "zone" only of the air conditioning system.

20)

Bring the engine speed to

2000 rpm

for approximately

1 minute

, then run at idle speed for

30

seconds

.

21)

Invert the temperature settings for the two air conditioning system "zones" (TGK valve_2 open and

TGK valve_1 closed).

22)

Bring the engine speed to

2000 rpm

for approximately

1 minute

, then run at idle speed for

30

seconds

.

23)

Close the heater circuit and top up if necessary.

24)

Repeat the procedure

twice

from step

19

to step

23

.

25)

Open the heater circuit, setting the maximum temperature for both "zones" of the air conditioning

system (TGK valve_1 and TGK valve_2 open); bring the engine speed to

2000 rpm

for approximately

1

minute

, then run at idle speed for

30 seconds

.

26)

Bring the engine speed to

2000 rpm

, close the heater circuit (TGK valve_1 and TGK valve_2 closed

and idle speed pump not running), then let the engine return to idle speed after

1 minute

.

27)

Switch off the engine and allow it to cool (water temperature

40-45°C

) for approximately

1h 30 min

.

Check the cooling system fluid level (

A3.07

).

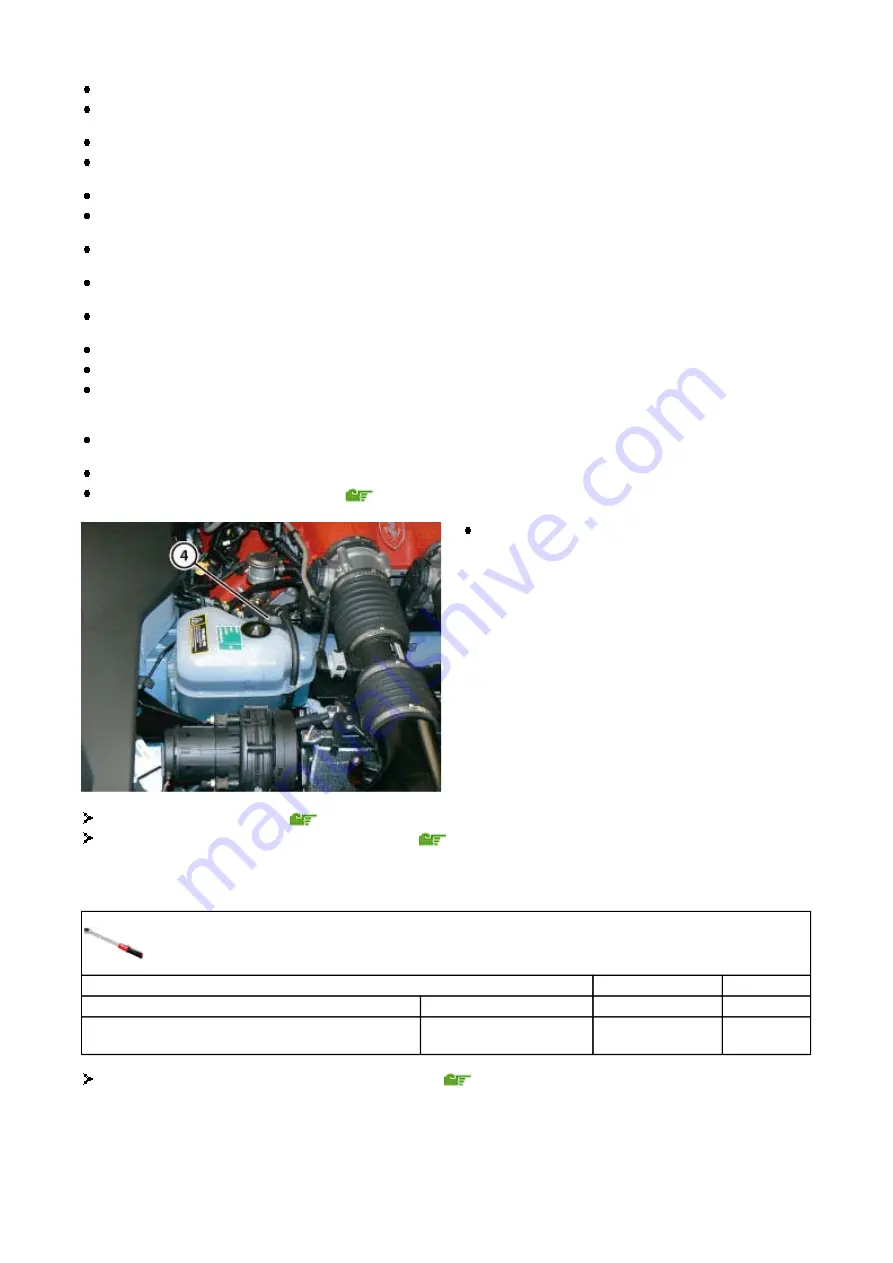

28)

Tighten the filler cap

(4)

completely onto the

expansion tank.

Refit the front wheelhouses (

E3.05

).

Refit the engine compartment cosmetic shields (

E3.13

).

Static filling (engine off) (ONLY for vehicles WITH Single oil heat exchanger)

Cap - front cover

M12x1.25x12 plug

30 Nm

B

Fastening water return pipe from single oil heat

exchanger fastening

Screw collar

4 Nm

B

Tightening torque

Nm

Class

Remove the engine compartment cosmetic shields (

E3.13

).

Summary of Contents for California

Page 19: ...Z Tyre type and pressure label ...

Page 20: ...04 02 Assembly number Assembly number A Assembly number label ...

Page 21: ...04 03 Chassis number Chassis number B Punched chassis number ...

Page 22: ...04 04 Engine type and number Engine type and number C Punched engine type and number ...

Page 23: ...04 05 Chassis number Chassis number D Chassis number ...

Page 24: ...04 06 Gearbox type and number Gearbox type and number E Gearbox type and number plate ...

Page 25: ...04 07 Vehicle identification Vehicle identification K VIN label Vehicle Identification Number ...

Page 28: ...04 10 Fuel Fuel I Fuel label ...

Page 29: ...04 11 Paintwork Paintwork L Paintwork label ...

Page 30: ...04 12 Emissions control Emissions control M Emissions control data label ...

Page 31: ...04 13 Airbag Airbag N Do not install child seat on passenger seat label ...

Page 32: ...04 14 Airbag Airbag O Airbag maintenance label ...

Page 33: ...04 15 Airbag Airbag P Airbag warning label ...

Page 43: ...Fluids and lubricants table Model Fluids and lubricants table Download ...

Page 71: ...Screw the cap A back on tightly ...

Page 104: ...Connect the battery F2 01 ...

Page 118: ...Vehicle Setup Parameter Check Form Model Vehicle Setup Parameter Check Form Download ...

Page 520: ...A DCT gearbox clutch oil tank and clutch oil pump B Clutch oil pipes C Clutch oil radiator ...

Page 623: ...CCM Brake Disc Wear Form Model All Models CCM Brake Disc Wear Form Download ...

Page 1070: ...A Horn button B Engine start button C Manettino ...

Page 1102: ...Perform the respective cycle with the DEIS diagnostic tester ...

Page 1144: ...Connect the battery F2 01 ...

Page 1220: ...Precautions and guidelines for using the RHT retractable hard top ...

Page 1334: ...Undo the indicated fasteners Retrieve the indicated shims Release the clip 1 ...

Page 1335: ...Remove the indicated clip Undo the indicated screw Undo the screws indicated ...

Page 1452: ...Refit the rear wheelhouses E3 05 Connect the battery F2 01 ...

Page 1453: ...F2 07 Lights Diagnosing condensation in headlamps ...

Page 1561: ...Ss Sensor signal λ Lambda ratio excess g Rich mixture M Lean mixture ...

Page 1570: ...Refit the DCT gearbox C2 03 Connect the battery F2 01 ...

Page 1656: ...G Heater evaporator H Pollen filter I Air vents M Expansion valve ...

Page 1677: ...Refit the front wheelhouses E3 05 ...

Page 1686: ...Refit the caps 1 Refit the engine compartment cosmetic shields E3 13 ...