Not for

Reproduction

37

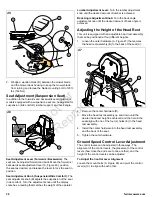

• More than .5" (12,7 mm) of the mower blade metal

has been removed from previous sharpening or wear

(A).

• The air lifts are excessively eroded (B) and the notch

(C) is .25" (6,35 mm) deep or greater.

• The mower blade is broken or bent.

42

4. If the cutting edges are not sharp or have nicks, sharpen

the blades.

WARNING

Thrown objects and fire hazard

Grinding mower blades throws sparks and fine metal

particles that are capable of igniting gasoline and gasoline

vapors, and that can injure unprotected eyes.

Be sure all flammable materials are cleared from the area

where grinding will occur.

Always wear safety glasses or goggles when grinding

mower blades.

5. Use a grinder, hand file, or electric blade sharpener to

sharpen the mower blades by removing an equal amount

of material from the cutting edge of each end of the blade.

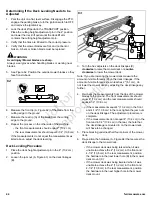

6. Keep the original bevel (A, Figure 43) when grinding. DO

NOT change the mower blade bevel.

43

7. The mower blade should have a maximum of 1/64" (0,40

mm) cutting edge (B) or less.

CAUTION

Thrown objects hazard.

An unbalanced mower blade can create excessive vibration

and damage the unit, or cause mower blade failure resulting

in thrown debris.

Be sure blade is balanced before installing.

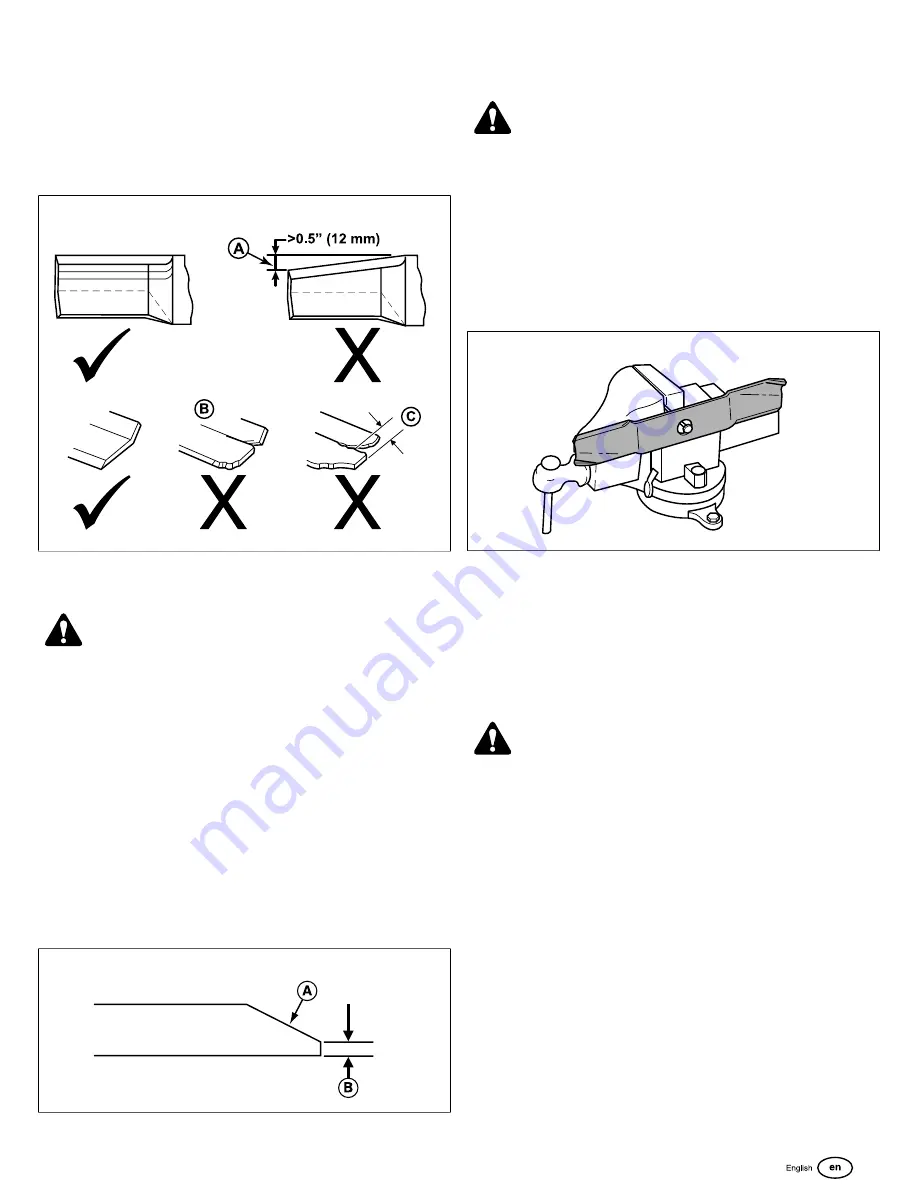

8. Clamp a nail in a bench vise, hang the blade on the nail,

and position the blade in a level horizontal position as

shown in Figure 44.

44

9. Check the balance of the blade. If either end of the

blade moves downward the end that moves downward

is heavier than the other. Sharpen the heavy end until

balance is achieved.

10. Repeat the process until the mower blade remains in the

horizontal, level position.

Installing the Mower Blades

CAUTION

Laceration hazard.

Mower blades are sharp.

Always wear gloves when handling, or working near, mower

blades.

1. Install each mower blade with the air lifts (C, Figure 45)

pointing up towards the mower deck as shown in Figure

45 and secure with the mower blade mounting bolt (A)

and flat washer (B).