MODENA S HE

26

EN

cod. 3541C364 - Rev. 00 - 12/2012

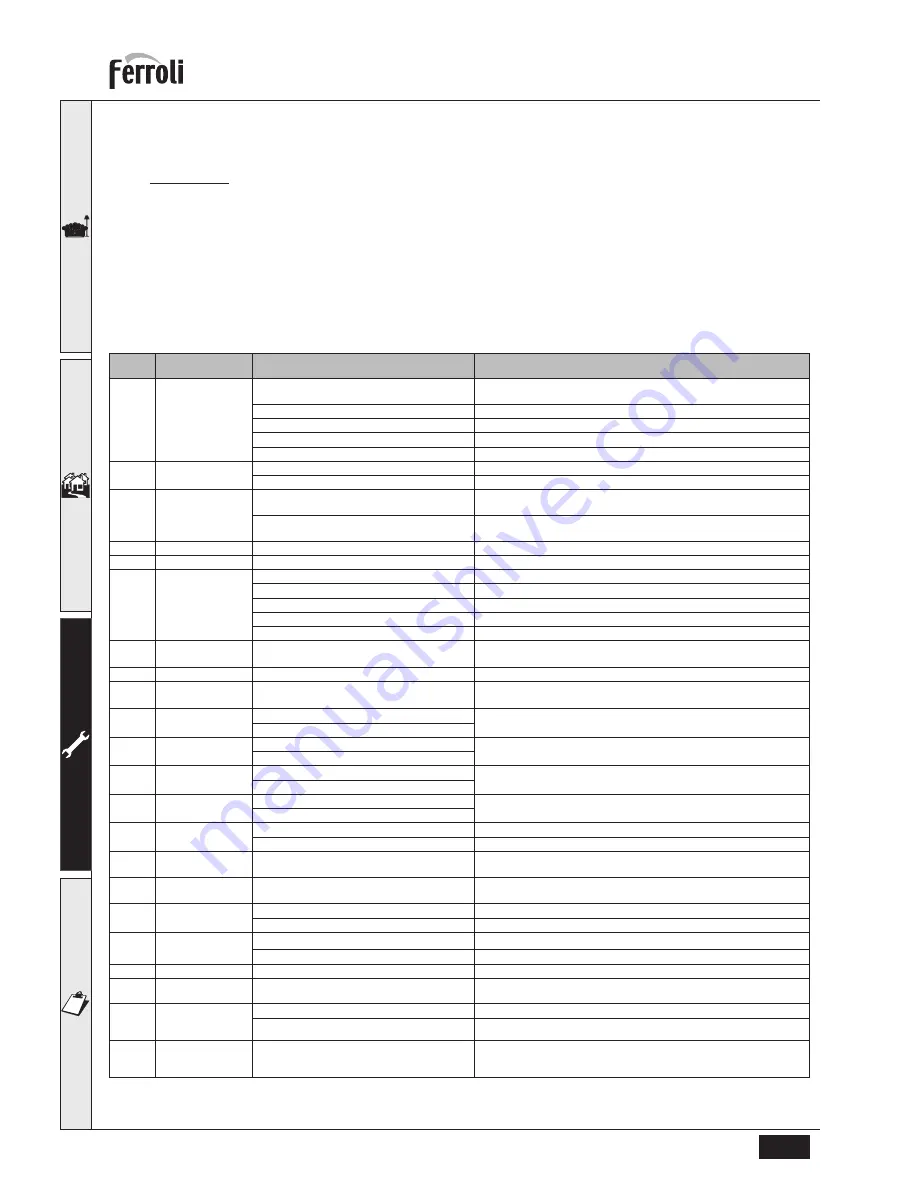

3.5 Troubleshooting

Diagnostics

The boiler is equipped with an advanced self-diagnosis system. In case of a boiler fault, the display will flash together

with the fault symbol (detail 11 - fig. 1) indicating the fault code.

Certain faults cause permanent boiler shutdowns (marked with the letter “

A

”): to restore operation, press the RESET

button (detail 6 - fig. 1) for 1 second or RESET on the optional remote timer control if installed; if the boiler fails to start,

it is necessary to firstly eliminate the fault.

other faults (indicated with the letter “

F

”) cause temporary shutdowns that are automatically reset as soon as the value

returns within the boiler's normal working range.

Table. 6 - List of faults

Fault

code

Fault

Possible cause

Cure

A01

No burner ignition

No gas

Check the regular gas flow to the boiler and that the air has been purged

from the pipes

Electrode fault

Check that the electrode is correctly positioned and free of any deposits

Defective gas valve

Check and change the gas valve

Incorrect inlet gas pressure

Check inlet gas pressure

Siphon obstructed

Check and if necessary change the siphon

A02

Flame detected with

the burner off

Electrode defective

Check the electrode wiring

Main board defective

Check the PCB

A03

High limit protection

Flow temperature sensor not active or correctly

located

Check the correct positioning and operation of the flow sensor

No system circulation

Check pump and radiator valves present in the system

Check operation of the internal by-pass

A04

Flue gas fault

Fault F07 happened 3 times in the last 24 hours

Check the exchanger

A05

Fan problem

Tachometer signal interrupted for 1 hour or longer Check the wiring and the fan

A06

No flame after the

ignition phase (6

times in 4 minutes)

Electrode fault

Check that the electrode is correctly positioned and if necessary change it

Flame unstable

Check the burner

Incorrect valve gas Offset

Check the Offset at the minimum power

Flue gas circuit obstructed

Check if flue gas circuit is free

Siphon obstructed

Check and if necessary change the siphon

A41

Flow sensor

disconnected

Sensor disconnected

Check the correct positioning and operation of the flow sensor

A42

Flow sensor fault

Sensor damaged

Change the sensor

F07

High fume

temperature

The exchanger probe detects and excessive

temperature

Check the exchanger

F10

Flow sensor fault

Sensor damaged or short circuited

Check the wiring or change the sensor

Sensor damaged or wiring broken

F11

Return sensor fault

Sensor damaged or wiring shorted

Check the wiring or change the sensor

Sensor damaged or wiring broken

F13

Exchanger probe

fault

Sensor damaged or wiring shorted

Check the wiring or replace the probe

Sensor damaged or wiring broken

F14

Flow sensor fault

Sensor damaged or short circuited

Check the wiring or change the sensor

Sensor damaged or wiring broken

F15

Fan problem

Tachometer signal interrupted, fan connection

Check the wiring and the fan

Fan damaged, debris in fan

Check the fan, clean debris

F34

Supply voltage under

170V

Electric supply problem

Check the electrical system

F35

Irregular mains

frequency

Electric supply problem

Check the electrical system

F37

Incorrect system

water pressure

Pressure too low

Fill the system

Sensor damaged

Check the sensor

F43

Exchanger

protection activation.

No system H

2

O circulation

Check the circulating pump

Air in the system

Vent the system

F52

Flow sensor fault

Sensor damaged

Change the sensor

A61

Controller

ABM03

fault

Controller

ABM03

internal error

Check the earth connection and replace the controller if necessary.

A62

No communication

between controller

and gas valve

Controller not connected

Connect the controller to the gas valve

Valve damaged

Replace the valve

A63

A64

F66

Controller

ABM03

fault

Controller

ABM03

internal error

Check the earth connection and replace the controller if necessary.