MODENA S HE

8

EN

cod. 3541C364 - Rev. 00 - 12/2012

2.2 Place of installation

The combustion circuit is sealed with respect to the

place of installation and therefore the unit can be in-

stalled in any room. However, the place of installation

must be sufficiently ventilated to prevent the creation

of dangerous conditions in case of even slight gas

leaks. This safety regulation is provided for by EEC Di-

rective no. 2009/142 for all gas units, including those

with a sealed chamber.

In any case, the place of installation must be free of dust,

flammable materials or objects or corrosive gases.

The boiler is arranged for wall mounting and comes

standard with a hanging bracket. A paper template for

marking the drilling points on the wall is provided in the

box. The wall fixing must ensure stable and effective

support for the generator.

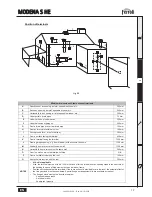

A

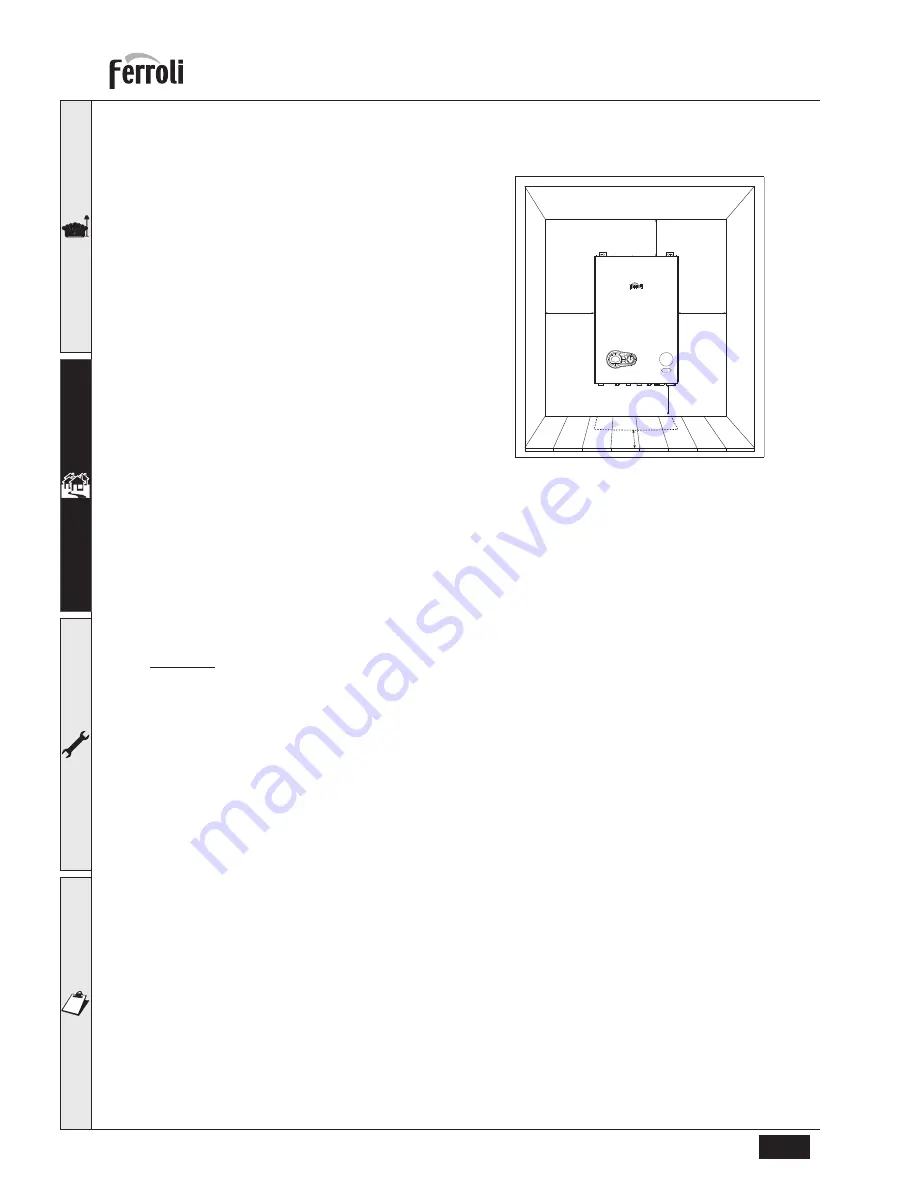

If the unit is enclosed in a cabinet or mounted

alongside, a space must be provided for re-

moving the casing and for normal mainte-

nance operations. The minimum

measurements to be respected are given in

fig. 9.

fig. 9 - Minimum distances around the boiler

A

Min. 2,5 cm

B

Min. 10 cm

C

Min. 30 cm

D

Min. 30 cm (via an openable panel)

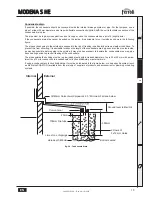

2.3 Plumbing connections

Important

The heating capacity of the boiler must be previously established by calculating the building's heat requirement according

to the current regulations. To ensure proper operation and long boiler life, the plumbing system must be adequately sized

and complete with all the necessary accessories, including a room thermostat, a thermostatic radiator valve (TRV), etc.

The system flow and return pipes must have a diameter of at least 22 mm for the first 3 m of length from the unit.

If the system delivery and return pipes follow a path where air pockets could form in certain places, it is advisable to

install vent valves at these points. Also, install type "A" drain cocks at the lowest points in the system to allow complete

emptying.

The temperature drop between the delivery manifold and the return to the boiler should not exceed 20 °C.

A flow rate of at least 6 litres/min through the heat exchanger is required. Bypass installed in the boiler guarantees main-

taining of the required flow rate.

B

Do not use the water system pipes to earth electrical appliances.

Before installation, carefully

flush

all the heating system pipes to remove any residuals or impurities that could affect

proper operation of the unit (as required by BS 7593 Building regs Doc L).

Carry out the connections to the unit as indicated in fig. 32.

B

The safety valve discharge must be connected to a 15 mm diameter copper pipe descending from the boiler

to run off system water in case of overpressure in the heating circuit.

Otherwise, the boiler manufacturer

cannot be held liable if the discharge valve operates and floods the room

. The discharge must be run

to the outside of the building to prevent the risk of damage or injury caused by discharged hot water in case

of overpressure in the system.

Connections to the boiler are to be made in such a way as to ensure that its internal pipes and fittings are free of stress.

If a non-return valve is installed also on the DHW circuit (if provided for), it is necessary to install a safety valve between

the boiler and circuit (with non-return valve at least 3 metres from the boiler) or an expansion tank for domestic use.

D

A

A

B

C