ATLAS D 30 PLUS UNIT

43

EN

cod. 3540U263 - 06/2012 (Rev. 00)

A

When the thermostatic line closes, the burner motor starts turning together with the

pump: all the oil sucked is sent to the return. The burner blower and the ignition trans-

former are also working, therefore the following stages are carried out:

•

firebox preventilation.

•

prewash of a part of the oil circuit.

•

preignition, with discharge between electrode tips.

B

At the end of prewash, the unit opens the electromagnetic valve: the oil reaches the noz-

zle, where it is finely sprayed.

Its contact with the discharge between the electrode tips creates the flame.

The safety time begins simultaneously.

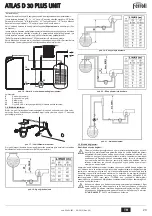

Unit cycle

fig. 31 - Unit cycle

R-SB-W

Thermostats/Pressure switches

OH

OIl pre-heater

OW

Operation enabling contact

M

Burner motor

Z

Ignition transformer

BV

Electromagnetic valve

FR

Photoresistance

A’

Starting with pre-heater

A

Starting without pre-heater

B

Flame present

C

Normal operation

D

Adjustment stop (TA-TC)

t1

Pre-ventilation time

TSA

Safety time

t3

Pre-ignition time

t3n

Post-ignition time

tw

Pre-heating time

Output signals from the unit

Necessary input signals

Checks during operation

•

Ignite the appliance as described in sec. 17.3.

•

Check that the fuel circuit and water systems are airtight.

•

Check the efficiency of the flue and air-fume ducts while the boiler is working.

•

Check that the water is circulating properly between the boiler and the systems.

•

Check the proper ignition of the boiler by performing various tests, turning it on and

off with the room thermostat or remote control.

•

Check that the burner door and fume chamber are tight.

•

Check that the burner works properly.

•

Analyse the combustion (with the boiler unit stable) and check that the content of

CO

2

in the fumes is between 11% and 12%.

•

Check the parameters are programmed correctly and perform any required custom-

ization (compensation curve, power, temperatures, etc.).

4.3 Maintenance

Periodical check

To ensure correct operation of the unit over time, have qualified personnel carry out a

yearly check, providing for the following:

•

The control and safety devices must function correctly.

•

The fume exhaust circuit must be perfectly efficient.

•

Check there are no obstructions or dents in the fuel supply and return pipes.

•

Clean the filter of the fuel suction line.

•

Measure the correct fuel consumption

•

Clean the combustion head in the fuel outlet zone, on the swirl disc.

•

Leave the burner running at full rate for approximately ten minutes, then analyse

the combustion, checking:

-

All the elements specified in this manual are set correctly

-

Temperatures of the fumes at the flue

-

CO2 percentage content

•

The air-fume end piece and ducts must be free of obstructions and leaks

•

The burner and exchanger must be clean and free of deposits. For possible clean-

ing do not use chemical products or wire brushes.

•

The gas and water systems must be airtight.

•

The water pressure in the cold water system must be approx. 1 bar; otherwise, bring

it to that value.

•

The circulating pump must not be blocked.

•

The expansion tank must be filled.

•

Check the magnesium anode and replace it if necessary.

A

The boiler casing, control panel and aesthetic parts can be cleaned with a soft

and damp cloth, if necessary soaked in soapy water. Do not use any abrasive

detergents and solvents.

Burner disassembly

•

Electrically disconnect the boiler.

•

Remove casing

“B”

by undoing screws

“A”

for access to all the accessories.

•

Undo nut

“C”

, extract and position the burner in order to access the nozzle.

fig. 32 - Burner disassembly

Boiler cleaning

1.

Disconnect the electrical power to the boiler.

2.

Remove the burner as previously described.

3.

Remove panels

“E”

and

“F”

by undoing the respective nuts.

4.

Clean the inside of the boiler and the entire path of exhaust fumes, using a tube

brush or compressed air.

5.

Refit the panels.

fig. 33

FR

Z

M

OW

OH

W

SB

R

BV

A

A

B

C

D

1

8

3

3

6

7

4

11

12

t3n

tw

t1

t3

TSA

C

B

A

F

E

Summary of Contents for ATLAS D 30 PLUS UNIT

Page 94: ......

Page 95: ......

Page 96: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it ...