BLUEHELIX B 32 K 50

46

EN

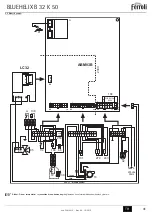

Connection to collective flues

fig. 19 - Examples of connection to flues (

= Air /

= Fumes)

Table. 9 - Typology

If the boiler is to be connected

BLUEHELIX B 32 K 50

to a collective flue or a single flue

with natural draught, the flue or chimney must be expressly designed by professionally

qualified technical personnel in conformity with the current regulations and be suitable

for sealed chamber units equipped with fan.

3.7 Condensate drain connection

B

ATTENTION: The unit must never be operated with the trap empty!

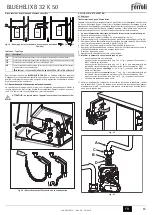

fig. 20 - Condensate outlet connection

4. SERVICE AND MAINTENANCE

4.1 Adjustments

Gas conversion

The unit can operate on Natural Gas or LPG and is factory-set for use with one of these

two gases, as clearly shown on the packing and on the data plate. Whenever a different

gas to that for which the unit is arranged has to be used, a conversion kit will be required,

proceeding as follows:

1.

Disconnect the boiler power supply and close the gas cock

.

2. Remove the front panel (see fig. 24).

3. Undo the screw and rotate the control panel (see fig. 21).

4. Unscrew ring

C

and remove gas pipe

A

from the gas valve (see fig. 22).

5. Replace nozzle

B

inserted in the gas pipe with that contained in the conversion kit,

interposing seal

D

(see fig. 22).

6. Refit gas pipe

A

and check the tightness of the connection.

7. Apply the label, contained in the conversion kit, near the data plate.

8. Refit the front panel.

9. Switch the boiler power on and open the gas cock.

10.

Modify the parameter for the type of gas

:

•

put the boiler in standby mode

•

press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds: the display

shows “

b01

“ flashing.

•

press the DHW buttons (details 1 or 2 - fig. 1) to set parameter

00

(for operation

with natural gas) or

01

(for operation with LPG).

•

press the

h

button (detail 4 - fig. 1) until

“b06”

flashes on the display.

•

press the

DHW

buttons (details 1 or 2 - fig. 1) to set parameter

55

(for operation

with natural gas) or

70

(for operation with LPG).

•

press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds.

•

the boiler will return to standby mode

11. Using a combustion analyser connected to the boiler fume outlet, check that the

CO

2

content in the fumes, with the boiler operating at max. and min. output, matches

that given in the technical data table for the corresponding type of gas.

fig. 21

fig. 22

Type

Description

C2X

Intake and exhaust in common flue (intake and exhaust in same flue)

C4X

Intake and exhaust in common and separate flues , but undergoing similar wind conditions

C8X

Exhaust in single or common flue and wall intake

B3X

Intake from installation room by means of concentric duct (that encloses the exhaust) and exhaust in

common flue with natural draught

IMPORTANT - THE ROOM MUST BE PROVIDED WITH APPROPRIATE VENTILATION

The boiler has an internal trap for draining condensate. Fit the inspection union

A

and

the hose

B

, pressing it in. Fill the trap with approx. 0.5 l. of water and connect the hose

to the disposal system.

cod. 3541D616 -

5HY

48

EN

BLUEHELIX B 32 K 50

cod. 3541H110 - Rev. 00 - 10/2015

Summary of Contents for BLUEHELIX B 32 K 50

Page 94: ......

Page 95: ......

Page 96: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it ...