DIVACONDENS D PLUS F 24

45

EN

cod. 3541P653 - Rev. 01 - 03/2021

Gas valve pre-calibration

1.

Connect a pressure gauge to monitor the gas valve outlet pressure.

2.

Enable the

Auto-setting

function (Parameter b12=1).

3.

Activate the calibration procedure by pressing the h button and Eco/Comfort

button together for 5 seconds. The message "Au-to" immediately appears (in two

successive flashes) and the burner is lit. Within 8 seconds (natural gas and LPG)

the boiler finds the ignition point. The ignition point, absolute minimum current Offset

(Parameter q01) and absolute maximum current Offset (Parameter q02) values are

stored by the card.

Gas valve calibration

1.

The display will show "q02" flashing; the modulation current is forced to the pre-cal-

ibration value of the absolute maximum current Offset parameter (Parameter q02).

2.

Press the DHW buttons to adjust the parameter "q02" until the maximum nominal

pressure minus 1mbar is reached on the pressure gauge. Wait 10 seconds for the

pressure to stabilise.

3.

Press the

DHW “+”

button to set the parameter

“q02”

until the maximum nominal

pressure is reached on the pressure gauge. Wait 10 seconds for the pressure to sta-

bilise.

4.

If the pressure read on the pressure gauge is different from the maximum nominal

pressure, proceed in increments of 1 or 2 units of the parameter "q02" by pressing

the

DHW “+”

button: after each change, wait 10 seconds for the pressure to stabi-

lise.

5.

When the pressure read on the pressure gauge is equal to the maximum nominal

pressure (the newly calibrated value of the parameter "q02" is automatically saved),

press the

heating “–”

button: the display will show "q01" flashing; the modulation

current is forced to the pre-calibration value of the absolute minimum current Offset

parameter (Parameter q01).

6.

Press the DHW buttons to adjust the parameter "q01" until the minimum nominal

pressure plus 0.5mbar is reached on the pressure gauge. Wait 10 seconds for the

pressure to stabilise.

7.

Press the

DHW “-”

button to adjust the parameter "q01" until the minimum nominal

pressure is reached on the pressure gauge. Wait 10 seconds for the pressure to sta-

bilise.

8.

If the pressure read on the pressure gauge is different from the minimum nominal

pressure, proceed in decrements of 1 or 2 units of the parameter

“q01”

by pressing

the

DHW “-”

button: after each change, wait 10 seconds for the pressure to stabi-

lise.

9.

When the pressure read on the pressure gauge is equal to the minimum nominal

pressure (the newly calibrated value of the parameter "q01" is automatically saved.),

recheck both adjustments by pressing the heating buttons and correct them if nec-

essary by repeating the procedure described above.

10. The calibration procedure ends automatically after 15 minutes or by pressing the

heating “+”

and Eco/Comfort buttons together for 5 seconds.

Checking of gas pressure values and adjustment with limited range

•

Check that the supply pressure complies with that indicated in the technical data ta-

ble.

•

Connect a suitable pressure gauge to the pressure sampling point

“B”

located

downstream from the gas valve.

•

Activate the

TEST

mode and follow the instructions for checking the gas pressures

at maximum power and minimum power (see next par.).

If the maximum and/or minimum nominal pressures read on the pressure gauge are dif-

ferent from those indicated in the technical data table, proceed with the next sequence.

•

Press the Eco/Comfort button for 2 seconds to go to the gas valve Calibration with

limited range mode.

•

The card goes to the setting

“q02”

; displaying the currently saved value by pressing

the DHW buttons.

•

If the

maximum pressure

read on the pressure gauge is different from the nominal

one, proceed in increments/decrements of 1 or 2 units of the parameter

“q02”

by

pressing the DHW buttons: after each change, the value is stored; wait 10 seconds

for the pressure to stabilise.

•

Press the heating “-” button (ref. 3 - fig. 1).

•

The card goes to the setting

“q01”

; displaying the currently saved value by pressing

the DHW buttons.

•

If the

minimum pressure

read on the pressure gauge is different from the nominal

one, proceed in increments/decrements of 1 or 2 units of the parameter

“q01”

by

pressing the DHW buttons: after each change, the value is stored; wait 10 seconds

for the pressure to stabilise.

•

Recheck both settings by pressing the heating buttons and if necessary correct

them by repeating the procedure described above.

•

Pressing the Eco/Comfort button for 2 seconds returns to TEST mode.

•

Deactivate

TEST

mode (see next par.).

•

Disconnect the pressure gauge.

TEST mode activation

Press the heating buttons (details 3 and 4 - fig. 1) together for 5 seconds to activate the

TEST

mode. The boiler lights at the maximum heating power set as described in the fol-

lowing section.

The heating and DHW symbols (fig. 22) flash on the display; the heating power will ap-

pear alongside.

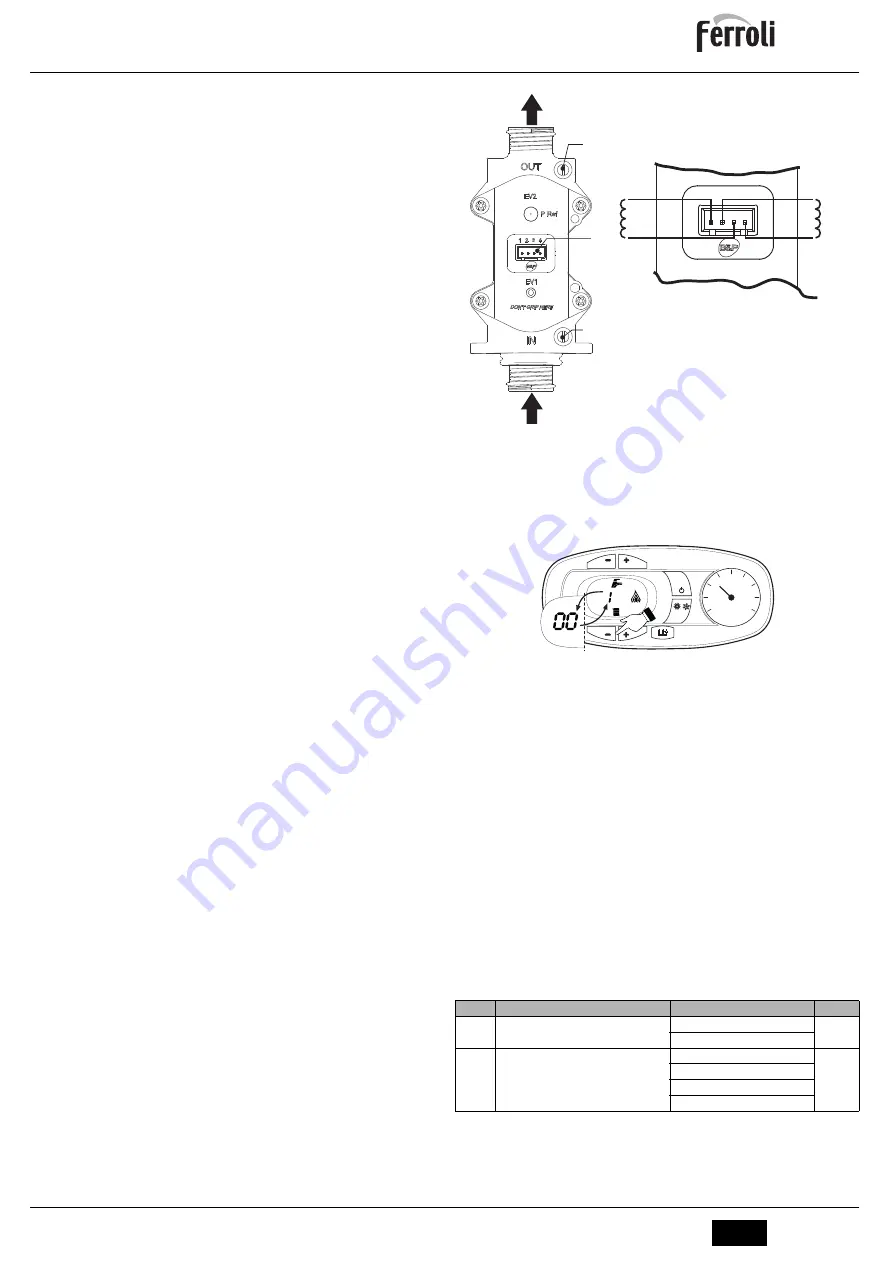

fig. 22 - TEST mode (heating power = 100%)

Press the heating buttons (details 3 and 4 - fig. 1) to increase or decrease the power

(Min.=0%, Max.=100%).

By pressing the DHW

“-”

button (detail 1 - fig. 1), boiler output is immediately adjusted

to min. (0%). By pressing the DHW

“+”

button (detail 2 - fig. 1), boiler output is immedi-

ately adjusted to max. (100%).

If the TEST mode is activated and enough hot water is drawn to activate the DHW mode,

the boiler remains in TEST mode but the 3-way valve goes to DHW.

To deactivate the TEST mode, press the heating buttons (details 3 and 4 - fig. 1) together

for 5 seconds.

The TEST mode is automatically deactivated in any case after 15 minutes or on stopping

of hot water drawing (if enough hot water has been drawn to activate the DHW mode).

Heating power adjustment

To adjust the heating power, switch the boiler to TEST mode (see sec. 4.1). Press the

heating buttons detail 3 - fig. 1 to increase or decrease the power (min. = 00 - max. =

100). Press the

reset

button within 5 seconds and the max. power will remain that just

set. Exit TEST mode (see sec. 4.1).

Configuration Menu

The configuration Menu is accessed by pressing the DHW buttons together for 10 sec-

onds.

12 parameters

, indicated by the letter "b” and not modifiable from Remote Timer

Control, are available.

Press the Heating buttons to scroll the list of parameters in increasing or decreasing or-

der. Press the DHW buttons to view or modify the value of a parameter: the change will

be automatically saved.

fig. 20 - Gas valve

A

- Upstream pressure point

B

- Downstream pressure point

I

- Gas valve electrical connection

R

- Gas outlet

S

- Gas inlet

fig. 21 - Gas valve connection

TYPE SGV100

Pi max 65 mbar

24 Vdc - class B+A

Contents Description

Range

Parameter

b01

Gas type selection

0=Natural Gas

0

1=LPG

b02

Boiler type selection

1=Bithermal instantaneous

2

2=Monothermal instantaneous

3=Heating only (3-way valve)

4=Heating only (circulating pump)

R

B

I

A

S

~ 65

W

~ 24

W

1 2 3 4

0

1

4

2

3

reset

eco

comfort

II

II

II

I I

I I I I I I

II

II

II

II

II

II

II

I I

I I I I I I

II

II

II

II

Summary of Contents for DIVACONDENS D PLUS F 24

Page 107: ......