DIVAtech F37 D

6

EN

cod. 3541H480 - Rev. 00 - 09/2015

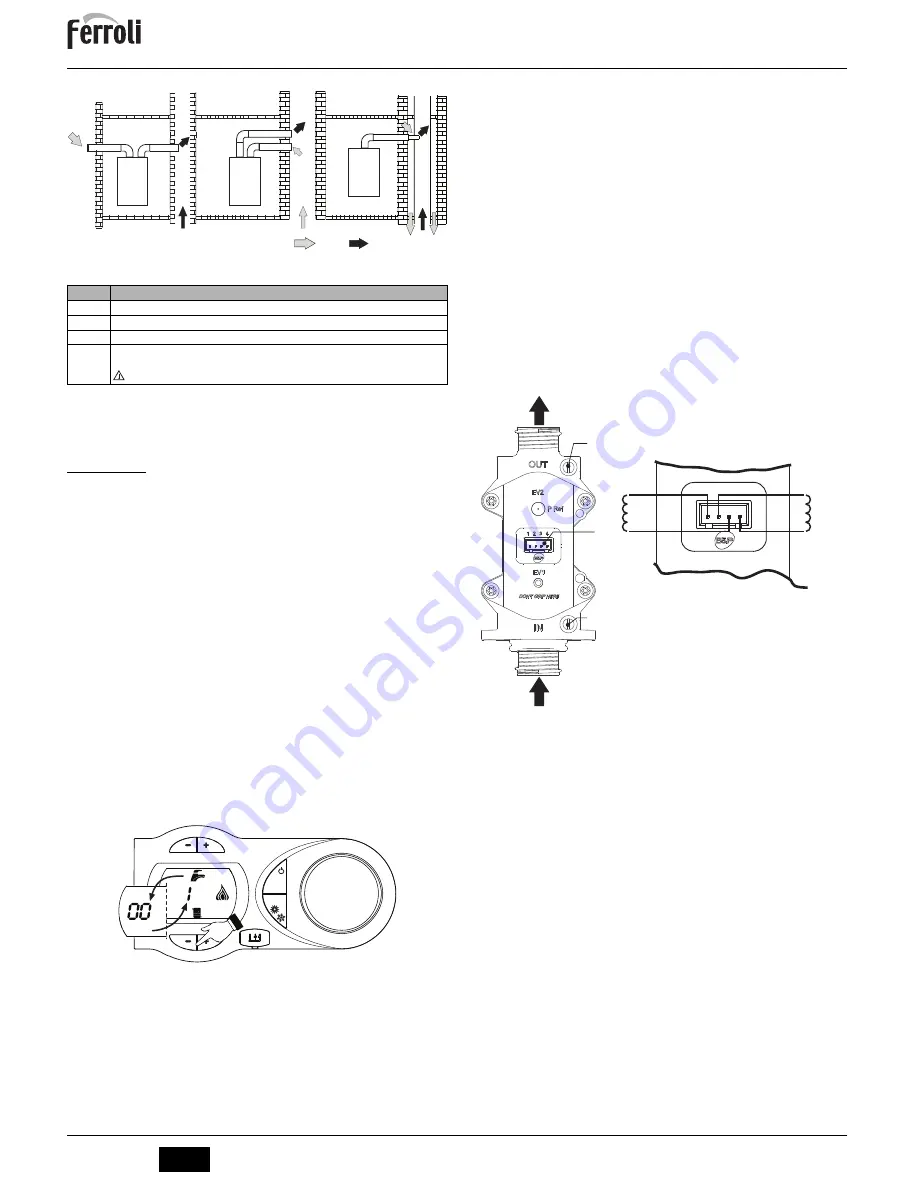

Connection to collective flues

fig. 13 - Examples of connection to flues (

= Air /

= Fumes)

Table. 7 - Typology

If the boiler is to be connected

DIVAtech F37 D

to a collective flue or a single flue with

natural draught, the flue or chimney must be expressly designed by professionally qual-

ified technical personnel in conformity with the current regulations and be suitable for

sealed chamber units equipped with fan.

4. SERVICE AND MAINTENANCE

4.1 Adjustments

Gas conversion

The unit can work on natural gas or LPG and is factory-set for use with one of these two

gases, as clearly shown on the packing and data plate. Whenever a different gas to that

for which the unit is arranged has to be used, the special conversion kit will be required,

proceeding as follows:

1.

Disconnect the power supply ahead of the boiler and close the gas cock;

2.

Replace the nozzles at the main burner and pilot burner, fitting the nozzles indicated

in the technical data table in cap. 5, depending on the type of gas used

3.

Connect the power supply ahead of the boiler and open the gas cock;

4.

Modify the parameter for the type of gas:

•

put the boiler in standby mode

•

press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds: the display

shows “

b01

“ flashing.

•

press the DHW buttons (details 1 and 2 - fig. 1) to set parameter

00

(for opera-

tion with natural gas) or

01

(for operation with LPG).

•

press the DHW buttons (details 1 and 2 - fig. 1) for 10 seconds.

•

the boiler will return to standby mode

5.

Adjust the minimum and maximum pressures at the burner (ref. relevant para-

graph), setting the values given in the technical data table for the type of gas used

6.

Apply the sticker, contained in the conversion kit, near the data plate as proof of the

conversion.

TEST mode activation

Press the heating buttons (details 3 and 4 - fig. 1) together for 5 seconds to activate the

TEST

mode. The boiler lights at the maximum heating power set as described in the fol-

lowing section.

The heating and DHW symbols (fig. 14) flash on the display; the heating power will be

displayed alongside.

fig. 14 - TEST mode (heating power = 100%)

Press the heating buttons (details 3 and 4 - fig. 1) to increase or decrease the power

(min.=0%, max.=100%).

Press the DHW button

"-"

(detail 1 - fig. 1) and boiler power is immediately adjusted to

min. (0%). Press the DHW button

"+"

(detail 2 - fig. 1) and boiler power is immediately

adjusted to max. (100%).

If the TEST mode is activated and enough hot water is drawn to activate the DHW mode,

the boiler remains in TEST mode but the 3-way valve goes to DHW.

To deactivate the TEST mode, press the heating buttons (details 3 and 4 - fig. 1) for 5

seconds.

The TEST mode is automatically disabled in any case after 15 minutes or on stopping of

hot water drawing (if enough hot water is drawn to activate the DHW mode).

Pressure adjustment at the burner

Since this unit has flame modulation, there are two fixed pressure settings: minimum and

maximum, which must be those given in the technical data table according to the type of gas.

•

Connect a suitable pressure gauge to the pressure point

"B"

downstream of the

gas valve.

•

Activate the TEST mode (see cap. 4.1).

•

Press the Eco/Comfort button for 2 seconds to access the gas valve Calibration mode.

•

The card goes to the setting “q02”; displaying the actually saved value, by pressing

the DHW buttons .

•

If the pressure gauge reading is different from the nominal maximum pressure, pro-

ceed by increases/decreases of 1 or 2 units of parameter “q02” by pressing the

DHW buttons : the value is stored after each modification; wait 10 seconds for the

pressure to stabilise.

•

Press the heating button “-” (ref. 3 - fig. 1).

•

The card goes to the setting “q01”; displaying the actually saved value, by pressing

the DHW buttons .

•

If the pressure gauge reading is different from the nominal minimum pressure, pro-

ceed by increases/decreases of 1 or 2 units of parameter “q01” by pressing the

DHW buttons : the value is stored after each modification; wait 10 seconds for the

pressure to stabilise.

•

Recheck both adjustments by pressing the heating buttons and adjust them if nec-

essary by repeating the above procedure.

•

Press the Eco/Comfort button for 2 seconds to return to the TEST mode.

•

Deactivate the TEST mode (see cap. 4.1).

•

Disconnect the pressure gauge.

Heating power adjustment

To adjust the heating power, switch the boiler to TEST mode (see sec. 4.1). Press the

heating buttons (detail 3 - fig. 1) to increase or decrease the power (min. = 00 - max. =

100). Press the

reset

button within 5 seconds and the max. power will remain that just

set. Exit TEST mode (see sec. 4.1).

Type

Description

C2X

Intake and exhaust in common flue (intake and exhaust in same flue)

C4X

Intake and exhaust in common and separate flues , but undergoing similar wind conditions

C8X

Exhaust in single or common flue and wall intake

B3X

Intake from installation room by means of concentric duct (that encloses the exhaust) and exhaust in

common flue with natural draught

IMPORTANT - THE ROOM MUST BE PROVIDED WITH APPROPRIATE VENTILATION

C

8X

C

2X

C

4X

eco

comfort

reset

II

II

II

I I

I I I I I I

II

II

II

II

II

II

II

I I

I I I I I I

II

II

II

II

fig. 15 - Gas valve

A

- Upstream pressure point

B

- Downstream pressure point

I

- Gas valve electrical connection

R

- Gas outlet

S

- Gas inlet

fig. 16 - Gas valve connection

TYPE SGV100

Pi max 65 mbar

24 Vdc - class B+A

R

B

I

A

S

~ 65

W

~ 24

W

1 2 3 4