Econcept 50 A

11

a

aaa

aaa

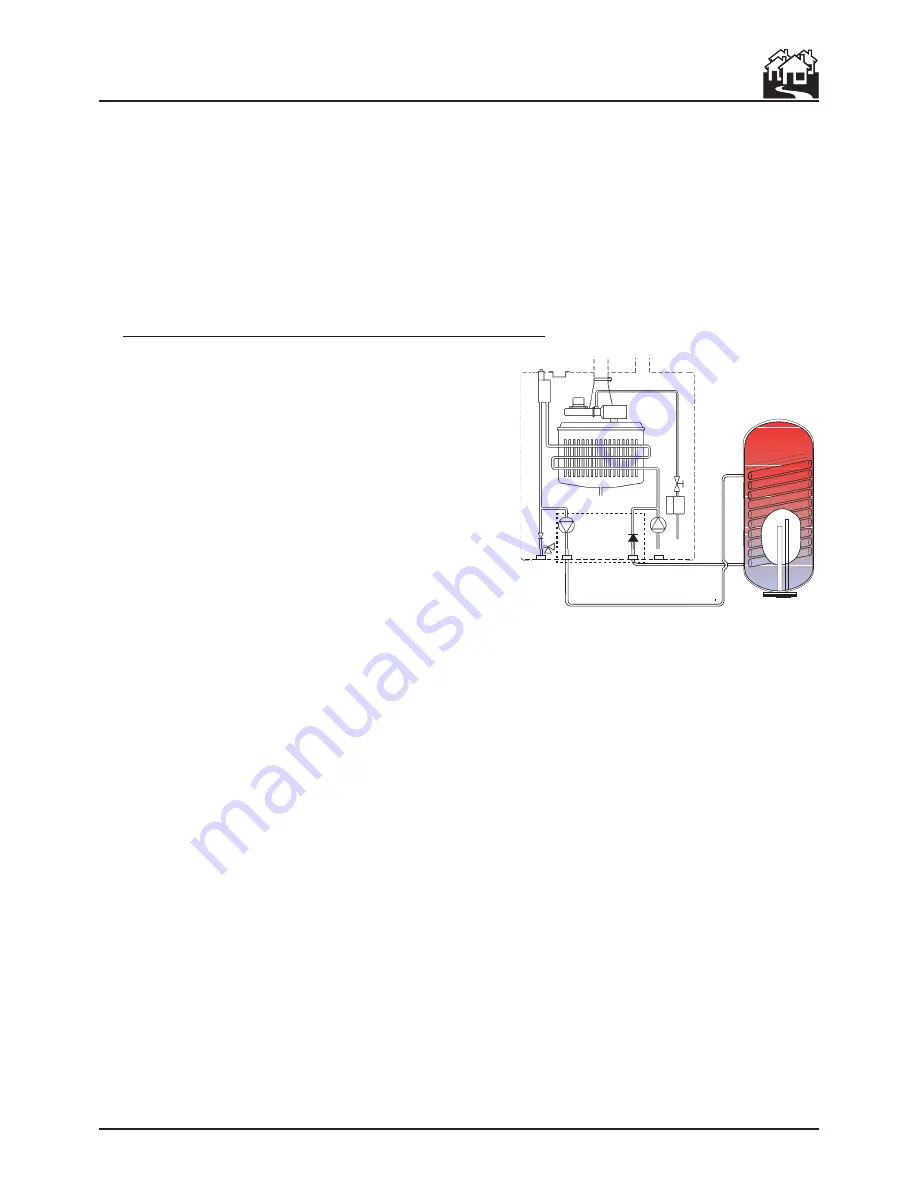

Kit 1KWMH17A

Cylinder not supplied

Fig. 4

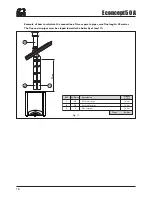

DHW calorifier connection(Optional kit 1KWMH17A)

The optional kit 1KWMH17A is available for connection

with an external cylinder. The kit, which includes circulator,

cylinder feeler and hydraulic pipe fittings, has to be mounted

inside the cylinder, according with instruction contained in

the kit itself. Then the connections have to be joined to the

cylinder.

2.4 Connection to the gas system

If necessary the local Gas supplier should be consulted, at

the installation planning stage, in order to establish the

availability of an adequate supply of gas.

An existing service pipe must

not

be used without prior

consultation with the Local Gas supplier.

A gas meter can only be connected by the Local Gas

supplier, or by a Local Gas suppliers Contractor.

Installation pipes should be fitted in accordance with

BS6891.

Appliance inlet working pressure must be 20mbar MINIMUM, for NG and 37 mbar minimum for LPG.

Pipework from the meter to the boiler must be of an adequate size.

Do not use pipes of a smaller size than the boiler inlet gas connection.

The complete installation must be tested for gas soundness and purged as described in BS6981. All pipework

must be adequately supported. An isolating gas valve should be fitted on the boiler gas inlet. Please wait

10 minutes when lighting from cold before checking gas rate. Gas pressures should be checked after the

boiler has operated for 10 minutes to ensure thermal equilibrium.

Make Up Water

Provision must be made for replacing water lost from the sealed system. Reference should be made to

BS6798, for methods of filling and making up sealed systems. There must be no direct connection between

the boiler's central heating system and the mains water supply. The use of mains water to charge and

pressurise the system directly, is conditional upon the Local Water Byelaws. Again any such connection must

be disconnected after use.

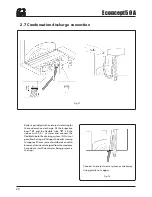

Always connect and filling device to the return pipework