Econcept 50 A

16

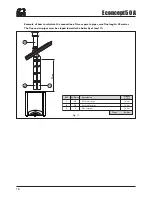

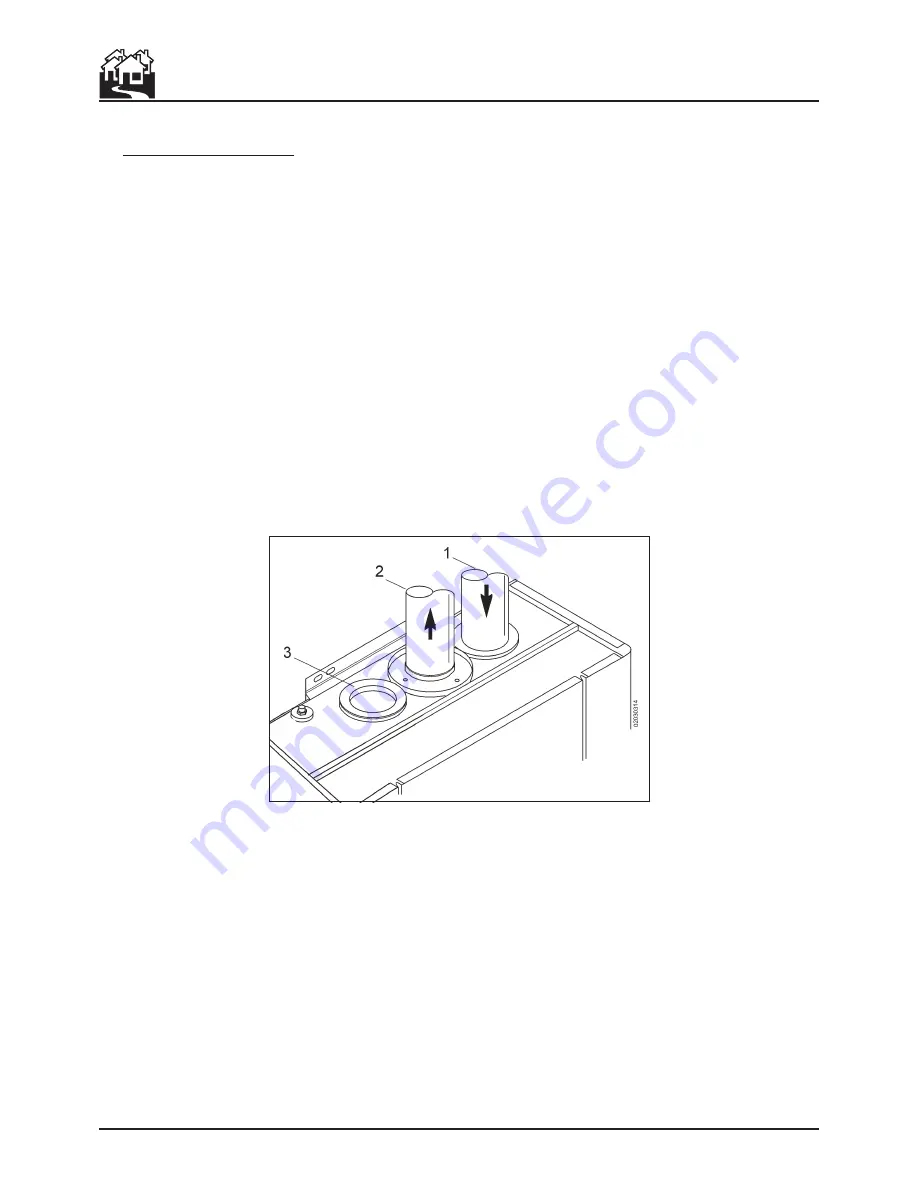

Two pipe flue system

The separate Ø80 pipes for air intake and flue gas exhaust can be connected directly to the boiler, as shown

in Fig. 10.

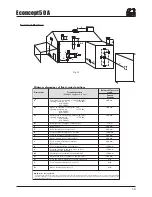

Upon request, a wide range of pipes, bends and accessories can be supplied. For the various components,

refer to tables 1-2 or to the flue accessory catalogue.

A simple calculation can be performed to ensure that the maximum allowable pipe length is not exceeded:

1

For each component, table 1-2 lists the loss of pressure in “equivalent air-metres”, depending on

the position of installation of the component itself (air intake or flue gas exhaust, vertical or

horizontal).

The loss is called “equivalent length” as it relates to the loss of length in the flue system due to

fuctional losses of bends. For example, a 90

°

Ø80 bend in flue gas exhaust has a loss equivalent to

2.5 air-metres, that is equal to 2.5 linear metres of flue pipe.

2

Once having completely defined the layout of the double flue system, add the losses in equivalent-

metres, according to the position of installation of all the components and accessories in the system

3

Check that the total loss calculated is less than or equal to

45 m

equivalent metres, that is the

maximum allowable for this model of boiler.

Fig. 10