ENERGY TOP B

65

EN

cod. 3540S738 - Rev. 00 - 01/2014

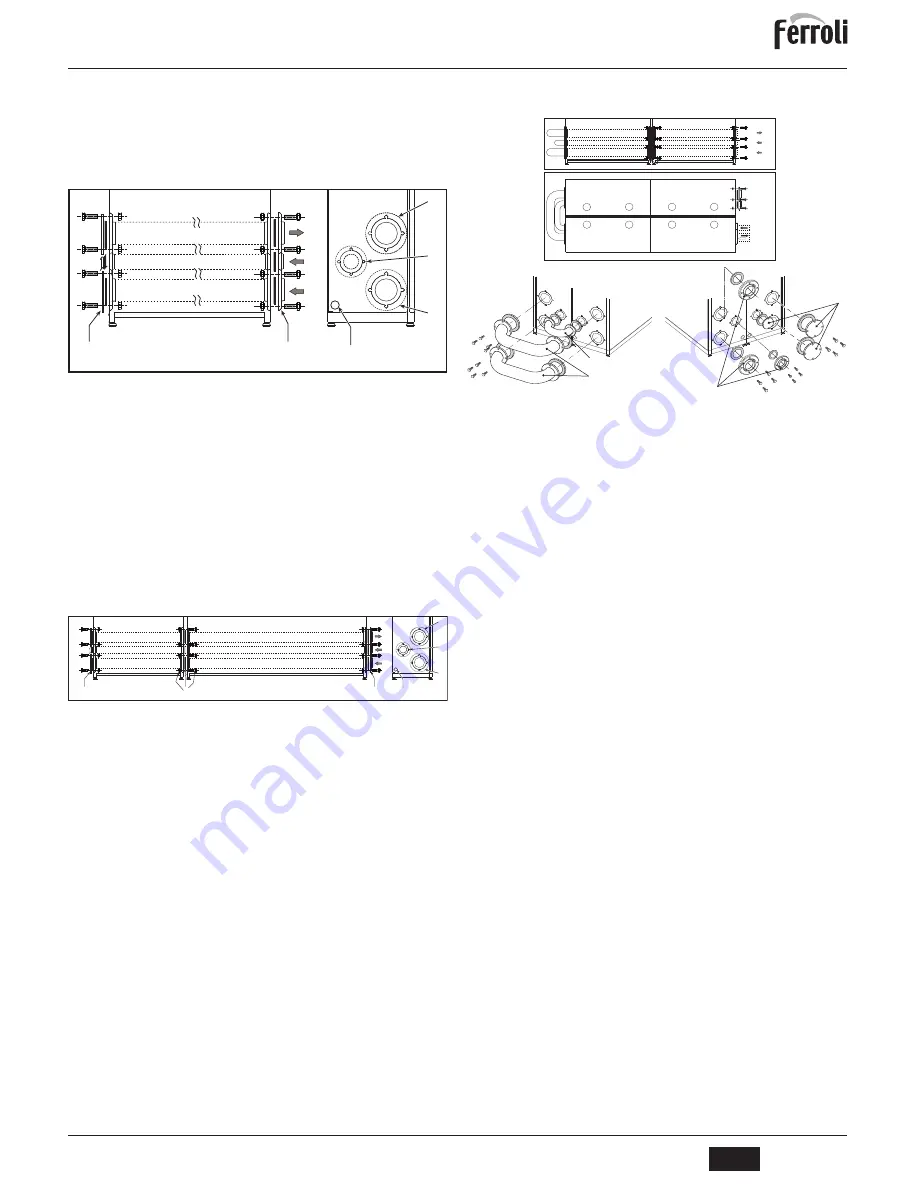

To connect a single module

•

After establishing on which side of the module to make the water and gas connec-

tions, connect the flanges with the joining section contained in the kit on that side

after suitably welding them to the system pipes. Make sure to correctly fit the special

seals contained in the kit.

•

Connect a Ø40 pipe to the condensate drain pipe for removing the condensate pro-

duced during operation (see fig. 48).

•

Fit the blind flanges contained in the kit on the opposite side of the module, placing

the special seals in between.

fig. 19

1

Gas inlet

2

System delivery

3

System return

4

Condensate drain

5

Blind flanges - kit 042027X0 (optional)

7

Blind flanges - kit 042027X0 (optional)

To connect several modules in line

•

Connect the first module to the system and gas pipes, as described above, but without

fitting the blind flanges on the opposite side of the module to that of the connection.

•

Connect the second module on this side, making sure to align the connection flang-

es and the condensate drain pipe. Place the seals contained in the kit between the

flanges of the two modules.

•

Fit the bolts contained in the kit on the flanges from the inside of the first module,

making them come out of the flanges in the second module. Partially tighten the nuts

on the bolts from inside the second module.

•

Before tightening the nuts, make sure all the seals are correctly positioned and fit

the condensate drain pipes of the two modules (see fig. 49).

•

Tighten the nuts and repeat the connection operations for the following modules.

fig. 20

1

Gas inlet

2

System delivery

3

System return

4

Condensate drain

5

Blind flanges - kit 042027X0 (optional)

7

Blind flanges - kit 042027X0 (optional)

8

Seals and screws (standard)

To connect several opposed modules

Optional kit code 042026X0 is available for connecting the water and gas manifolds in

series. The kit contains 3 flanged "U" pipes.

fig. 21 - Kit for connection of opposed modules

A

1st Module

B

2nd Module

C

3rd Module

D

4th Module

1

Gas inlet

2

System delivery

3

System return

5

Blind flanges

7

Drilled flanges

8

Seals and screws (standard)

•

Arrange the modules according to the layout of fig. 21.

•

Connect the first module to the system and gas pipes using the flanges with pipe

section and respective seals contained in the

kit 042027X0

.

•

Position the second module, making sure to align the connection flanges and the con-

densate drain pipe. Fit the seals (supplied) between the flanges of the two modules.

•

Fit the bolts (supplied) on the flanges from inside the first module, making them

come out the flanges in the second module. Partially tighten the nuts on the bolts

from inside the second module.

•

Before tightening the nuts, make sure all the seals are correctly positioned and fit

the condensate drain pipes of the two modules (see fig. 49).

•

Tighten the nuts and repeat the connection operations for the "U" pipes and next

modules. Fit the blind flanges contained in the

kit 042027X0

on the last module.

Safety device and separator module (optional)

The

Safety Device and Separator Module

for series

ENERGY TOP B

modular gener-

ators is an ISPESL certified module containing a hydraulic separator and safety, protec-

tion and control devices required by file "R" section R3A and R3B, intended for use with

series ENERGY TOP Bmodular generators .

Every

ISPESL

Safety Device Module comprises a cabinet of the same size and appear-

ance as the modular generators ENERGY TOP B, containing a hydraulic separator with

air valve and thermal insulation, the respective system delivery and return manifolds, a

gas manifold, and a discharge manifold for the safety valve. The safety devices required

by file "R" section R3A and R3B are fitted on the hydraulic manifolds and hydraulic sep-

arator body. Provision is also made for the probe pocket of a possible fuel shutoff valve,

to be installed in the system , on the outside of the bank of modules.

The

hydraulic separator

contained in the module allows the hydraulic circuit of the mod-

ules

ENERGY TOP B

(primary circuit) to be made independent of the hydraulic circuit of

the respective heating system (secondary circuit). The separator is sized for correct op-

eration up to 1000 kW, and the main advantages offered are:

•

An external circulating pump for the primary circuit is not necessary. In fact, circula-

tion in the primary circuit is ensured by the circulating pumps contained inside the

generators

ENERGY TOP B

.

•

When the secondary pump is deactivated, also the circulation in the system circuit

stops; the entire flow delivered by the circulating pumps contained inside the gener-

ators

ENERGY TOP B

is bypassed through the hydraulic separator.

•

The flow in the primary circuit can remain constant, whereas the secondary circuit

can function with a variable or intermittent flow rate.

•

There are no anomalous operating conditions in which the system pumps interact

with the circulating pumps in side the generators

ENERGY TOP B

, creating unwant-

ed head and flow-rate variations in the circuits.

•

Sizing of the system circulating pump can be carried out according to the needs of

just the secondary circuit.

2

1

3

4

7

5

2

1

3

2

1

3

4

7

2

1

3

8

5

2./.3

1

2

1

3

7

5

8

A

B

6

(

2

3

1

Summary of Contents for ENERGY TOP B 125

Page 23: ......

Page 24: ......

Page 25: ...FERROLI S p A Via Ritonda 78 a 37047 San Bonifacio Verona ITALY www ferroli it ...