ENERGY TOP B

73

EN

A

If the Remote Timer Control (optional) is connected to the boiler, the above ad-

justments are managed according to that given in table 1.

Table. 1

System water pressure adjustment

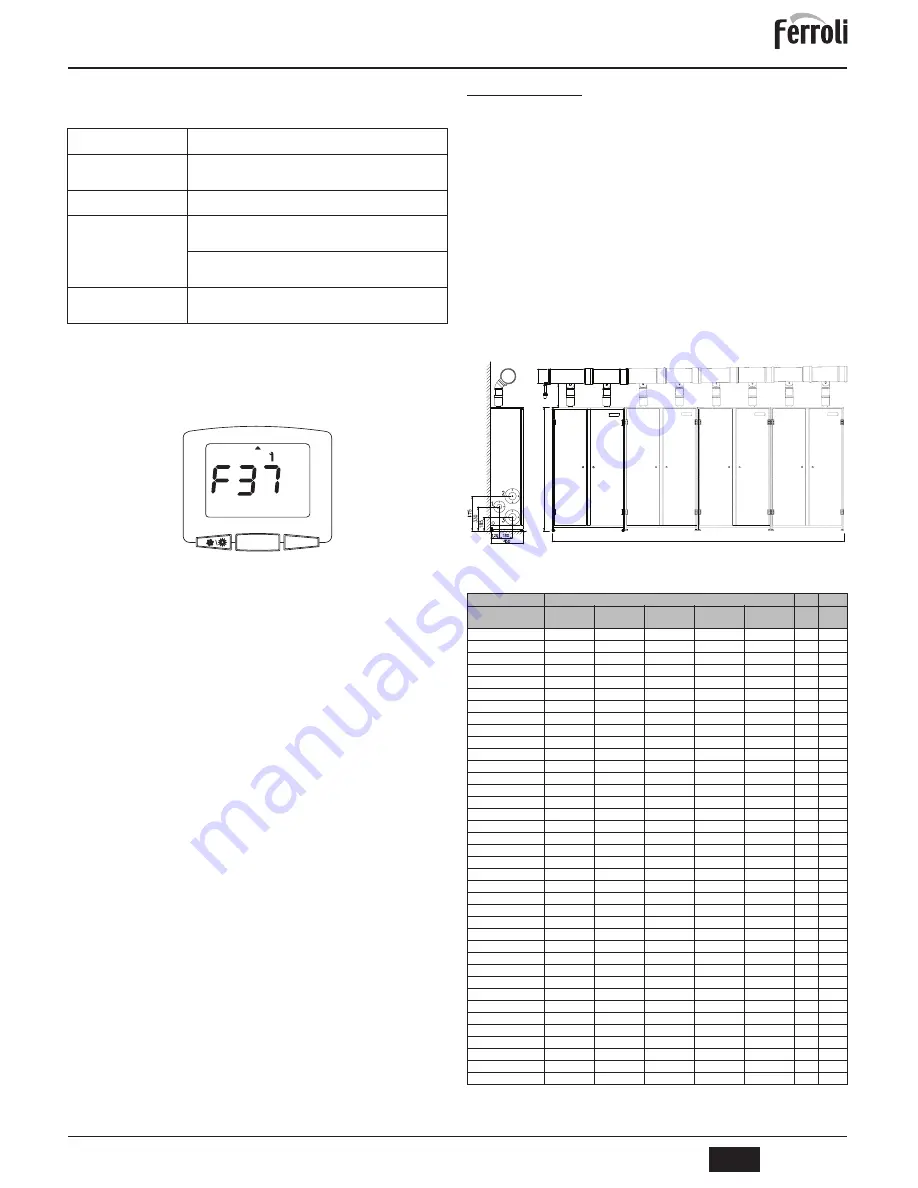

The filling pressure with the system cold must be approx. 1.0 bar. If the system pressure

falls to values below minimum, the boiler card will activate fault F37 (fig. 14). Flashing of

the arrows (details 18 and 24 - fig. 1) together with the error code indicates which boiler

shell is in fault status.

fig. 14 - Low system pressure fault

A

Once the system pressure is restored, the boiler will activate the 120-second

air venting cycle indicated on the display by FH.

3. INSTALLATION

3.1 General Instructions

THE BOILER MUST ONLY BE INSTALLED BY QUALIFIED PERSONNEL, IN COMPLI-

ANCE WITH ALL THE INSTRUCTIONS GIVEN IN THIS TECHNICAL MANUAL, THE

PROVISIONS OF CURRENT LAW, THE NATIONAL AND LOCAL REGULATIONS,

AND THE RULES OF PROPER WORKMANSHIP.

ENERGY TOP B is a heat generator arranged to operate alone or in cascade (bank).

When two or more generators are installed in cascade with the original kits ENERGY

TOP B, respecting the prescriptionsFERROLIof this manual, they can be considered as

a single heat generator of total power equal to the sum of the powers of all the units con-

nected in cascade.

All the requirements of the current standards and regulations applicable to this "equiva-

lent" total heating capacity generator must be met. In particular, the place of installation,

safety devices and fume exhaust system must be adequate for the total heating capacity

of the bank of units.

In fact, each ENERGY TOP B is a complete and independent heat generator, equipped

with its own safety devices. In case of overtemperature, no water or no circulation in the

unit , the protection devices cause the unit to shutdown , preventing its operation.

The installation instructions given in the following paragraphs concern single units and

connection in cascade.

Given below are the possible configurations for connection in cascade.

Configurations in line

fig. 15 - Configuration - in line (example with 4 modules)

Table. 2 - Configurations in line

Heating temperature adjustment

Adjustment can be made from the Remote Timer Control menu and the boiler

control panel.

DHW temperature adjustment

(with optional hot water tank

installed)

Adjustment can be made from the Remote Timer Control menu and the boiler

control panel.

Summer/Winter Switchover

Summer mode has priority over a possible Remote Timer Control heating

demand.

Eco/Comfort selection

(with

optional hot water tank installed)

On disabling DHW from the Remote Timer Control menu, the boiler selects the

Economy mode. In this condition, the button detail 7 - fig. 1 on the boiler panel

is disabled.

On enabling DHW from the Remote Timer Control menu, the boiler selects the

Comfort mode. In this condition it is possible select one of the two modes with

the button detail 7 -fig. 1.

Sliding Temperature

Both the Remote Timer Control and the boiler card manage Sliding Tempera-

ture adjustment: of the two, the Sliding Temperature of the boiler card has prior-

ity.

reset

eco

comfort

IIII

IIIIIIIIIIIIII

IIII

IIII

IIII

IIII

III

III

III

III

III

IIII

IIIIIII

IIIIIIIIIIIIIIII

IIIII

IIII

IIII

IIIII

IIIIII

IIII

IIII

Heating power

Combinations

max.

kW

Model

Module 1

Model

Module 2

Model

Module 3

Model

Module 4

Model

Module 5

Ø;

A

75

80

/

/

/

/

/

500

116

125

/

/

/

/

/

500

150

160

/

/

/

200

1000

232

250

/

/

/

200

1000

225

160

80

/

/

/

200

1500

266

160

125

/

/

/

200

1500

307

250

80

/

/

/

200

1500

348

250

125

/

/

/

200

1500

300

160

160

/

/

/

200

2000

382

250

160

/

/

/

200

2000

464

250

250

/

/

/

200

2000

375

160

160

80

/

/

200

2500

416

160

160

125

/

/

200

2500

457

250

160

80

/

/

200

2500

498

250

160

125

/

/

300

2500

539

250

250

80

/

/

300

2500

580

250

250

125

/

/

300

2500

450

160

160

160

/

/

300

3000

532

250

160

160

/

/

300

3000

614

250

250

160

/

/

300

3000

696

250

250

250

/

/

300

3000

525

160

160

160

80

/

300

3500

566

160

160

160

125

/

300

3500

607

250

160

160

80

/

300

3500

648

250

160

160

125

/

300

3500

689

250

250

160

80

/

300

3500

730

250

250

160

125

/

300

3500

771

250

250

250

80

/

300

3500

812

250

250

250

125

/

300

3500

600

160

160

160

160

/

300

4000

682

250

160

160

160

/

300

4000

764

250

250

160

160

/

300

4000

846

250

250

250

160

/

300

4000

928

250

250

250

250

/

300

4000

1003

250

250

250

250

80

300

4500

1044

250

250

250

250

125

300

4500

1078

250

250

250

250

160

300

5000

1160

250

250

250

250

250

300

5000

1700

A

325

Ø

cod. 3541H060 - Rev. 02 - 04/2018