FALCON II

19

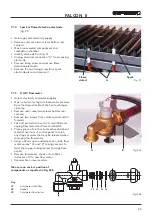

3.05 Connecting the central heating and domestic hot water circuits

Connect to the relevant connections as indicated in fig. 1. Connect the pressure relief valve discharge pipe

(15mm) to the outside of the building, where possible over a drain. The discharge must be such that it will not

be hazardous to occupants and passers-by or cause damage to external electric components or wiring. The

pipe should be directed towards the wall. To ensure long life, the heating circuit should be correctly sized and

fitted with all the controls necessary to ensure correct functioning and operation. The differential between

the boiler flow and return pipes should not be more than 20°C. You are advised not to use the boiler

with return temperatures of less than 50°C in order to prevent patches of condensation forming, having a

corrosive effect on boiler components.

3.06 Boiler water characteristics

If the water is harder than 18 clarke degrees, the water used should be treated to avoid possible scale in the

boiler caused by hard water or corrosion by aggressive water. It should be remembered that as a result of its

low thermal conductivity, even scale of just a few millimetres thick can lead to considerable overheating of

the boiler walls, resulting in serious problems.

IT IS ABSOLUTELY VITAL THAT THE WATER USED IS TREATED IN THE FOLLOWING CASES:

a) Extensive systems (containing large quantities of water);

b) Frequent additions of water to top-up the system;

c) Domestic hot water circuits

If the system requires partial or total emptying, you are recommended to refill it with treated water.

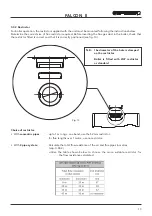

3.07 Filling

When cold, system pressure should be about 1 bar. If while running venting off of air dissolved in the water causes

the pressure of the central heating system to drop below 0.5 bar, the user must utilise a filling loop to bring it

back to the original value. During operation, water pressure in the boiler when hot should be about 1.5 - 2 bars.

After filling, always close and disconnect the filling loop.

Note -

If there is a possibility of air pockets forming in certain points of the central heating system flow and return

pipes, you are recommended to fit an air vent valve at these points.

Note -

When the boiler is installed below the level of the central heating a system, single check valve should be

fitted in the flow to prevent gravity circulation around the heating system.

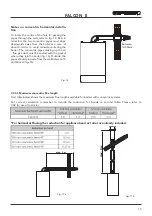

3.08 Gas connection

Gas connection should be carried out using a rigid pipe.

The flow at the gas meter should be sufficient for the simultaneous use at full gas rate of all appliances

connected to it. Connect the gas supply to the boiler according to current regulations. The diameter of

the gas tube leaving the boiler is not the determining factor in choosing the diameter of the pipe between

the appliance and the meter. This must be selected in relation to length and pressure drop and in any

instance should not be less than 22mm.

The whole of the gas installation including the meter should be inspected and tested for soundness and

purged in accordance with BS6891-1988.

N.B. -

The filling loop will be fitted by the installer at the time of installing the system.

It is NOT a

part of the boiler.

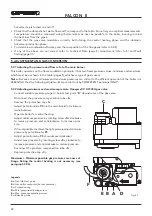

3.09 Electrical connection

The boiler must be connected to a single phase 230 V 50 Hz electricity supply with a 3 A max. fuse and a bipolar

switch with contact opening of at least 3 mm fitted between the boiler and the electricity supply. The boiler must

always be connected to an efficient earth installation. Under the electrical box, there is a 3 pole terminal block for

connecting the boiler to the mains (230 V 50 Hz) and a 2 pole board for connecting a room thermostat (RT). To connect,

undo the screws fixing the terminal block box and connect the wires, ensuring correct polarity of the terminals. It

should be noted that there is low voltage (24 V) between the room thermostat contacts.