14

FERSYSTEM TECH 38 C

Cod. 3540U330 - 09/2009 (Rev. 00)

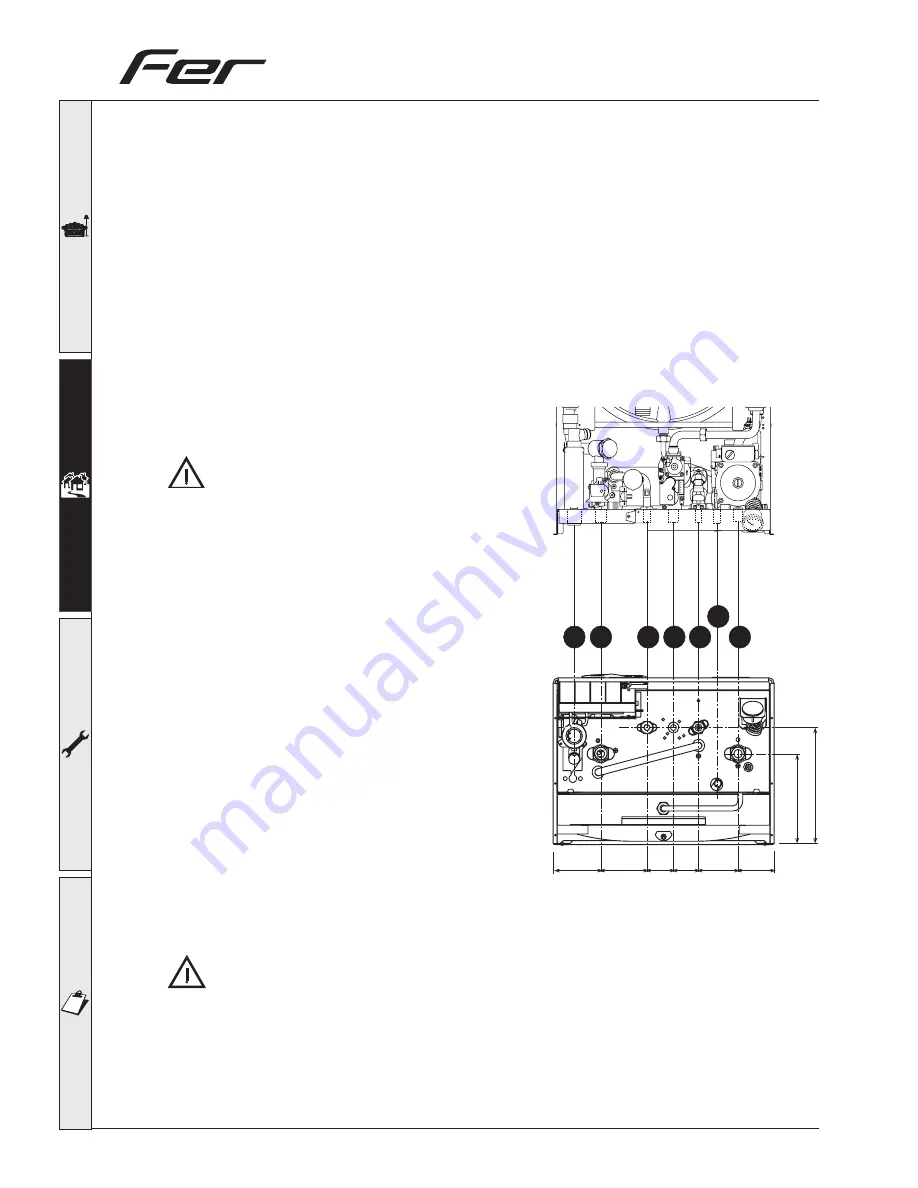

fig. 16

97

94

54 51 80.5 73.5

179,2

231,2

1

2 3

5

7

6

4

2.3 Boiler water connections

The heating capacity of the unit should be previously established by calculating the building’s heat requi-

rement according to current regulations. For good operation and long life of the boiler, the plumbing

system must be well proportioned and always complete with all those accessories that guarantee regular

operation and running, room thermostat, trv’s etc. The flow and return must be a minimum diameter of

22 mm for the first 3 metres from the appliance.

If the flow and return pipes follow a path where air pockets could form in certain places, it is essential to

install vent valves at these points. Also, install type “A” drain cocks at the lowest points in the system

to allow complete draining.

The temperature differential between the flow manifold and the return to the boiler should not exceed

20° C.

A minimum flow of 6 litres/min is required through the heat exchanger. An automatic by-pass is fitted

to the boiler which will provide this flow rate in most circu-

mstances.

Do not use the water system pipes to earth electrical

appliances.

Before installation, carefully flush all the pipes of the heating

system to remove residues or impurities that could affect the

unit’s operation (BS 7593 Building regs Doc L).

Make the connections to the appliance as shown in fig. 16

Key

1

System flow (22 mm with isolation valve fitted)

2

DHW outlet (15 mm )

3

Gas inlet (22 mm with isolation valve fitted)

4

Cold main inlet (15 mm with isolation valve fitted)

5

System return - 22 mm with isolation valve fitted (c/w filter)

6

Pressure Relief Valve

7

Condense outlet

It is essential to install the isolation valves supplied between the boiler and heating system, allowing the

boiler to be isolated from the system if necessary.

The safety valve outlet must be connected to a 15mm diameter copper pipe, with a continual

fall from the boiler to allow system water out onto the ground in the event of over-pressure in

the heating circuit. If this is not done, and the drain valve trips and floods the room, the boiler

manufacturer is not to be held responsible. The outlet should face back against the outer bri-

ckwork or building face to prevent harm or injury from hot water discharging in the event of an

over-pressurised system.

Make the boiler connection in such a way that its internal pipes are free of stress. If a check valve is

installed on the tap water circuit (where applicable), it is necessary to mount a safety valve between the

boiler and this circuit (check valve minimum 3 metres from boiler) or a domestic expansion vessel.

Summary of Contents for FERSYSTEM TECH 38 C

Page 37: ......