Optimax 25 OV

14

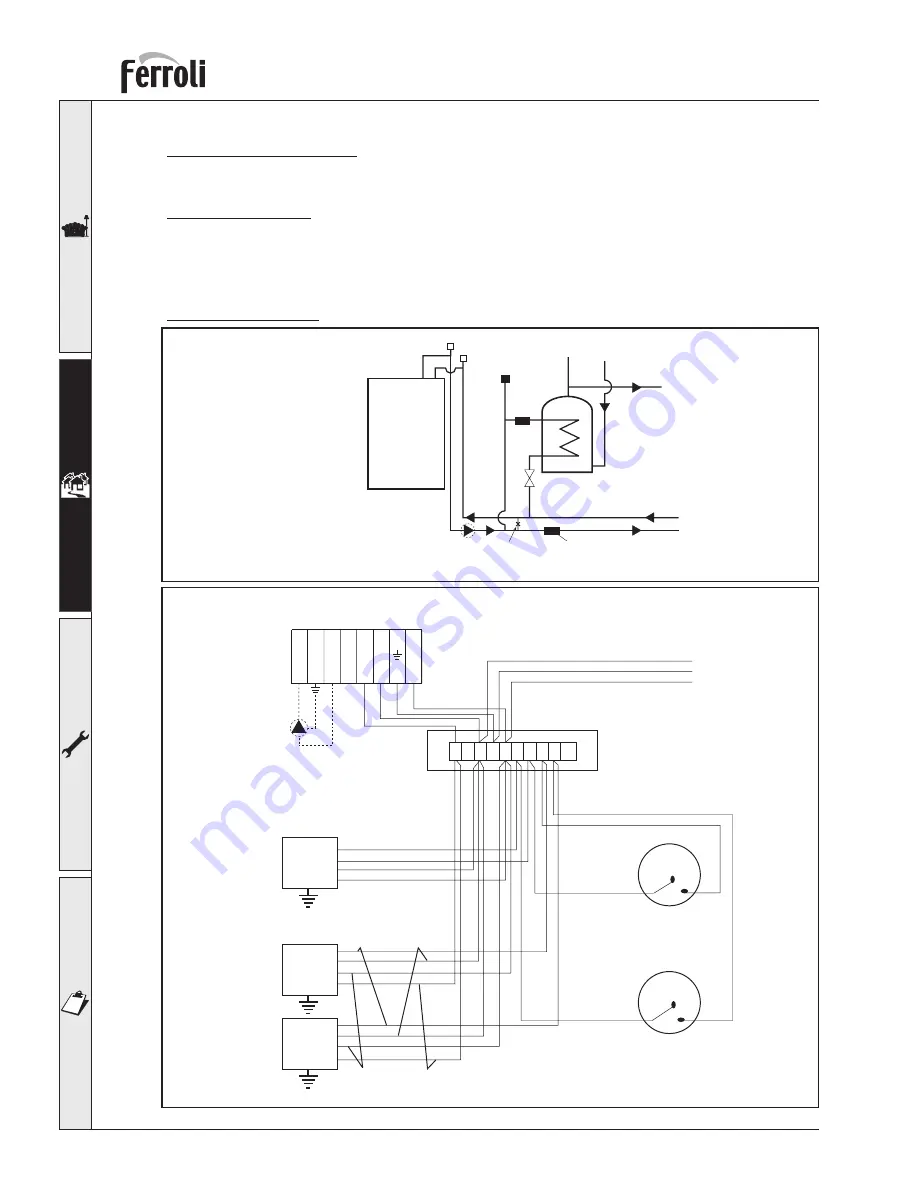

Central heating request

The heat demand can be done by the room thermostat (terminal 4-5) or by a switch line phase 230 V

(terminal 4).

Standard Systems

For a general pipe layout and wiring diagram on the “S” and “Y” plan systems please see fi g.

6a, 6b, and 7a, 7b.

OPTIMAX “S” Plan

Pipe layout

Wiring diagram

OPTIMAX

FERROLI

BOILER

Balancing

valve

C.H.

Zone Valve

Automatic

bypass

(mimimum flow of 6l/min.)

A.A.V

A.A.V

DHW

zone

valve

*Note:

cold feed and expansion

not shown for clarity

(see fig. 5)

Auto air vent

4

3

2

1

Junction Box

N E

L

Terminal 4

SWITCH LINE

1 2 3 4 5 6 7 8 9 10

PROGRAMMER

DHW ON

CH ON

NEUTRAL

LIVE

CH

zone

valve

DHW

zone

valve

Room Thermostat

Cylinder Thermostat

N

E

L

230 Volt A/C

fused at

3 amps

BROWN

BLUE

GREY

ORANGE

L

7

6

5

8

Fig. 6a

Fig. 6b

Remove

connection

between

terminals 4-5

Summary of Contents for OPTIMAX 25 OV

Page 35: ......