QUADRIFOGLIO B

96

EN

cod. 3541D501 - Rev. 03 - 12/2013

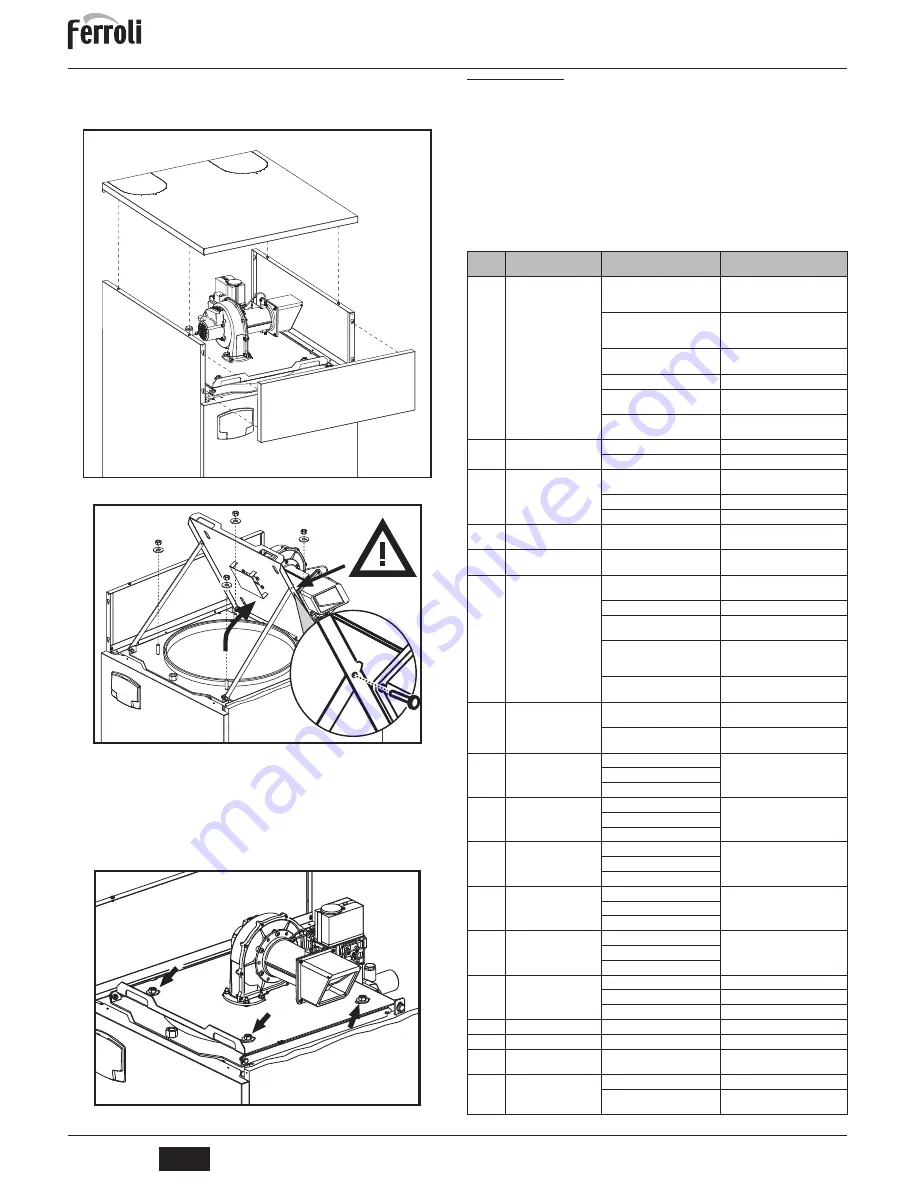

To access the burner observe the following instructions.

1.

Remove the top front panel and cover (fig. 68).

2.

Remove the four nuts and washers (fig. 69).

3.

Open the burner door (fig. 69).

fig. 68

fig. 69

B

After opening the burner door and hooking it to the support arms a pin

must (compulsory) be inserted in the safety hole (ref. A - fig. 69), to avoid

the risk of accidental release during maintenance operations.

To close it, repeat these operations in reverse order.

B

Tighten down the 4 nuts (fig. 70).

Then check the perfect tightness of the gas circuit.

fig. 70

4.4 Troubleshooting

Diagnostics

The boiler is equipped with an advanced self-diagnosis system. In the case of a boiler

fault, the display will light up, indicating the fault code and, in case of connection in cas-

cade, the number of the module.

There are faults that cause permanent shutdown (marked by the symbol

OK

to reset): to

restore operation, just press the

OK button

for 1 second or

RESET

on the remote timer

control (optional) if installed; if the boiler fails to start, the fault must be eliminated first.

Other faults cause temporary shutdowns which are automatically reset as soon as the

value returns within the boiler's normal working range.

Table of faults

Table. 4 - List of faults

A

Fault

code

Fault

Possible cause

Cure

A01

No burner ignition

No gas

Check the regular flow of gas to the

boiler and that the air has been

eliminated from the pipes

Ignition/detection electrode fault

Check the wiring of the electrode and

that it is correctly positioned and free

of any deposits

Faulty gas valve

Check the gas valve and replace it

if necessary

Insufficient gas supply pressure

Check the gas supply pressure

Trap blocked

Check the trap and clean it if

necessary

Faulty ignition transformer (only

models B 220 and B 320)

Check and replace it if necessary

A02

Flame present signal with

burner off

Electrode fault

Check the ionisation electrode wiring

Card fault

Check the card

A03

Overtemperature protection

intervention

Heating sensor damaged

Check the correct positioning and

operation of the heating sensor

No water circulation in the system

Check the circulating pump

Air in the system

Vent the system

A04

Fume extraction duct safety

device intervention

Fault F07 generated 3 times in the

last 24 hours

See fault F07

A05

Fan protection intervention

Fault F15 generated for 1 hour

(consecutive)

See fault F15

A06

No flame after ignition stage

(6 times in 4 minutes)

Ionisation electrode fault

Check the position of the ionisation

electrode and replace it if necessary

Flame unstable

Check the burner

Gas valve Offset fault

Check the Offset adjustment at

minimum power

air/fume ducts obstructed

Remove the obstruction from flue,

fume exhaust ducts and air inlet and

terminals

Trap blocked

Check the trap and clean it if

necessary

F07

High fume temperature

Flue partially obstructed or

insufficient

Check the efficiency of the flue, fume

extraction ducts and outlet terminal

Fume sensor position

Check the correct positioning and

operation of the fume sensor

F10

Delivery sensor 1 fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F11

Return sensor fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F12

DHW sensor fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F13

Fume sensor fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F14

Delivery sensor 2 fault

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

F15

Fan fault

No 230V power supply

Check the 3-pin connector wiring

Tachometric signal interrupted

Check the 5-pin connector wiring

Fan damaged

Check the fan

F34

Supply voltage under 170V Electric mains trouble

Check the electrical system

F35

Faulty mains frequency

Electric mains trouble

Check the electrical system

F37

Pressure switch contact

open

Low system pressure

Check the system water pressure

F39

External probe fault

Probe damaged or wiring shorted

Check the wiring or replace the sensor

Probe disconnected after activating

the sliding temperature

Reconnect the external probe or

disable the sliding temperature