Rendimax N EL

24

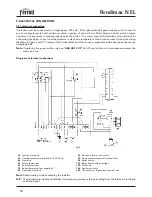

fig. 13

Key

1

Casing cover

2

Smokebox closing plate

3

Brush

3

2

1

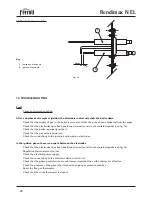

13. CHECKS AND MAINTENANCE

Attention

The boiler’s electrical devices work at 230v ~ 50hz.

Before carrying out any work, make sure the electrical power is removed.

13.01 checking the system boiler (to be performed once a year

The system checks are generally performed at the end of the winter season. Check that the water in central heating

circuit is pressurised. Verify serviceability and operation of the pumps.

Check the correct operation of the boiler by effecting ignition and shut-down tests using the regulation thermo-

stat.

Check on the rear wall of the boiler, at the height of the draught diverter, that there are no flue gas leaks, signs of

blockages of the flue or insufficient draught.

Check the effectiveness of the flue during the operation of the boiler.

Check that the connecting pipe between the boiler and flue is perfectly sealed at the joints.

Check that, in the absence of a flame in the burner assembly, the appliance shuts-down and the light on the reset

button 11, fig. 1, turns on.

13.02 cleaning the boiler and chimney (to be performed once every 3 years)

To properly clean the boiler, proceed as follows:

• Close the gas upstream from the appliance and remove electrical power.

• Remove the boiler door.

• Lift the cover of the casing, applying upwards pressure (fig. 13).

• Remove the smokebox closing plate.

• Remove the burner assembly (see 13.03).

• Clean from top to bottom, using a brush. The same operation can be

performed from bottom to top.

• Clean the flue gas discharge pipes between the cast-iron elements of

the boiler body, using a vacuum cleaner.

• Carefully replace all the previously removed parts and check the gas

circuit and flue pipes for tightness.

• Make sure when cleaning not to damage the bulb of the flue gas

thermostat, fitted at the rear of the smokebox.