S.p.A.

9

SUN

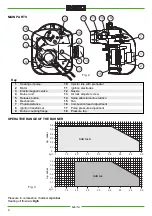

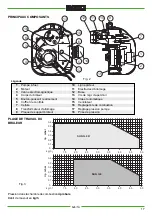

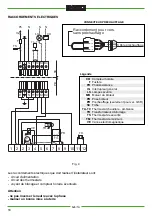

POSITION OF ELECTRODES - BAFFLE (Fig. 9)

After having mounted the injector, check

that the electrodes and baffle are correctly

positioned according to the above listed

measurements.

Always check the measurements

whenever operations are carried out on

the head.

3

1

L

45.0

°

6.5

3.5

Fig. 9

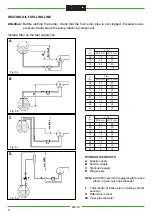

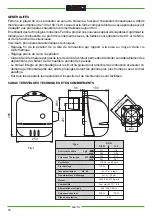

kW

23,3

34,9

46,5

kcal/h

20.000

30.000

40.000

Burner

flow rate

Kg/h

2,176

3,25

4,35

US

Gall/h

0,6

0,85

1,1

1,0

Angle

60

°

60

°

60

°

60

°

Code

3560154/0

3560134/0

3560128/0

3560127/0

Pump

pressure

Bar

12

12

12

12

Air

regulation

Tacca

5

10

15

15

kcal/h

22.200

33.200

44.400

kW

25,8

38,7

51,6

Tacca

6

10

15

18

L

18

22

27

31

*

*

*

*

*

*

*

Delivered heat

output

Head

adjustment

MODEL

BOILER

GN1.02

GN1.03

GN1.04

Heat rate

Injector

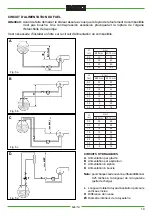

COMBUSTION HEAD AND AIR

DAMPER ADJUSTMENT (Fig. 8)

The combustion head is adjusted accord-

ing to burner flow rate. To adjust, rotate

the adjustment screw (B) clockwise or

anticlockwise until the notch on the rod

“A” coincides with the indicator.

This modifies the position of the deflec-

tor in relation to the draught tube and con-

sequently the passage of air.

The air flow rate is adjusted via screw “C”.

When the burner shuts down, the air

damper closes automatically.

EXAMPLE OF COMBUSTION REGU-

LATION

The injector, pump pressure, combustion

head adjustment and air flow rate regula-

tion must be established according to the

flow rate required by the boiler, as indi-

cated in the following chart check com-

bustion.

Fig. 8

C

A

B

* Regulations for without preheater burner version