SUN P7 - P12

11

EN

cod. 3540I815 - 07/2011 (Rev. 00)

EN

1. GENERAL INSTRUCTIONS

•

Carefully read the instructions contained in this instruction booklet.

•

After boiler installation, inform the user regarding its operation and give him this

manual, which is an integral and essential part of the product and must be kept with

care for future reference.

•

Installation and maintenance must be carried out by professionally qualified person-

nel, according to current regulations and the manufacturer's instructions. Do not car-

ry out any operation on the sealed control parts.

•

Incorrect installation or inadequate maintenance can result in damage or injury. The

Manufacturer declines any liability for damage due to errors in installation and use

or failure to follow the instructions.

•

Before carrying out any cleaning or maintenance operation, disconnect the unit from

the power supply using the system switch and/or the special cut-off devices.

•

In case of a fault and/or poor operation, deactivate the unit and do not attempt to

repair it or directly intervene. Contact professionally qualified personnel. Repair/re-

placement of the products must only be carried out by professionally qualified using

original spare parts. Failure to comply with the above could affect the safety of the

unit.

•

This unit must only be used for its intended purpose. Any other use is considered

improper and therefore dangerous.

•

The packing materials are potentially hazardous and must not be left within the

reach of children.

•

The images given in this manual are a simplified representation of the product. In

this representation there may be slight and insignificant differences with respect to

the product supplied.

2. OPERATING INSTRUCTIONS

2.1 Introduction

Dear Customer,

Thank you for choosing

SUN P7 - P12

, a

FERROLI

burner featuring advanced design,

cutting-edge technology, high reliability and quality construction.

SUN P7 - P12

is a pellet burner whose compact size and original design make it suitable

for use with the majority of solid fuel-burning boilers available on the market. The care

taken in its design and industrial production has resulted in a well-balanced product of-

fering high efficiencies, low CO and NOx emissions and a very quiet flame.

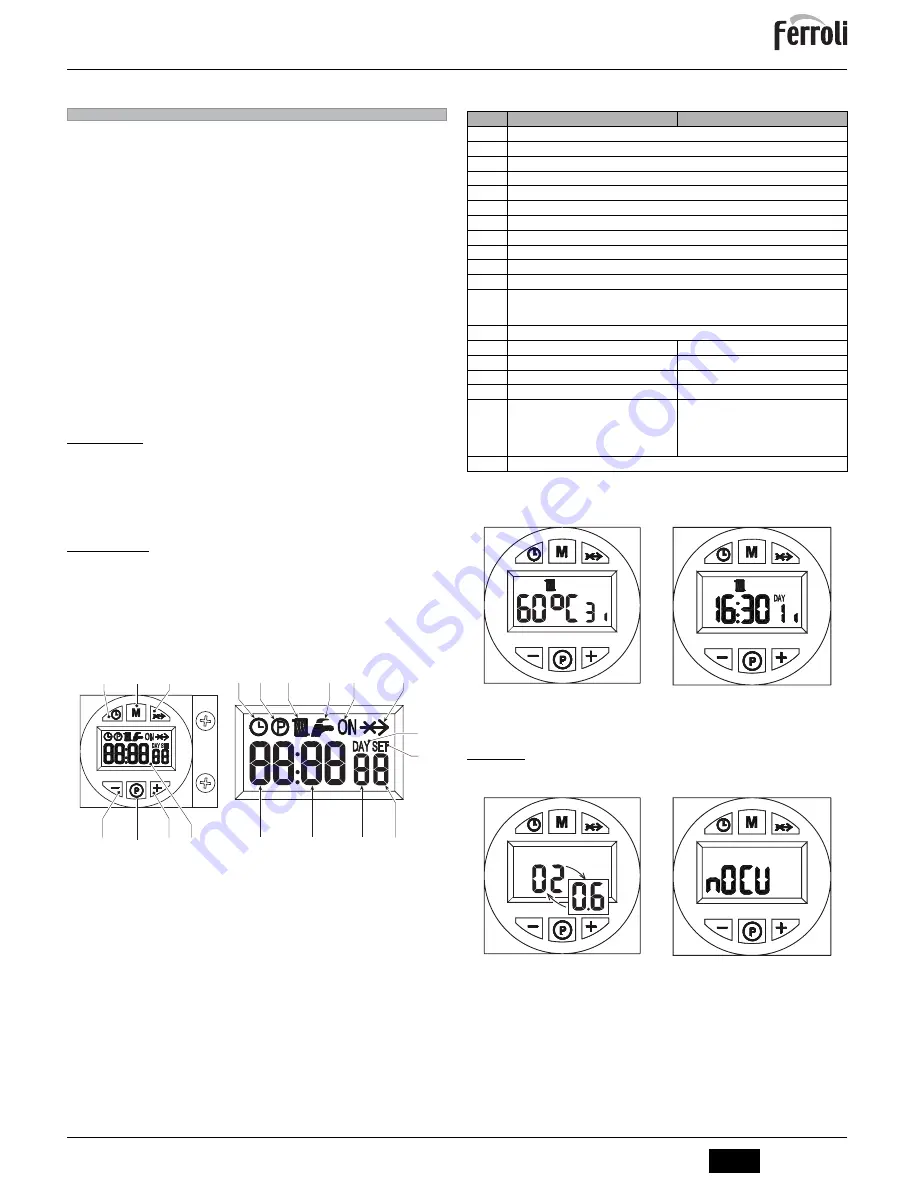

2.2 Control panel

Display

The display shows various information, depending on the set operation method.

There are 3 operation methods:

•

A

= Burner management (Default setting)

•

B

= Burner management (Second internal clock or contact)

•

C

= Burner management (Second internal clock or contact)

Display

fig. 1 - Control panel

Key

Indications during operation

The lighting request (generated on closing of the contact on terminals 7-8 (see fig. 17),

in default setting conditions) is indicated by activation of the radiator symbol (detail 10 -

fig. 1).

2.3 Lighting

Switch on the power to the unit:

•

During the first 10 seconds the display shows:

-

The software version of the user interface and the controller (method A only)

-

“nOCU” (methods B and C only)

•

The burner does a pre-ventilation of the combustion chamber.

•

At the end of this time, the burner will be ready to work.

8 9

16

17

18

19

10

11 12

13

14

15

1

2

3

4

5

6 7

Ref.

fig. 1

Method A

Methods B and C

1

Day/time setting button

2

Operation mode selection button

3

Override button

4

- button

5

Programming button

6

+ button

7

Display

8

Automatic mode symbol

9

Programming Menu symbol

10

Burner lighting request symbol

11

Not used

12

Multifunction symbol:

•in Automatic mode, it indicates when the programmer clock is in the request band

•if Automatic mode was not selected it indicates Manual On mode

13

Override symbol

14

Deactivated symbol

Day symbol

15

Deactivated symbol

Setting symbol

16

Heating sensor temperature

Current time

17

°C symbol

Current minutes

18

Actual burner power

1

= Minimum

5

= Maximum

O/FH

= During Pre-ventilation/Post-ventilation

6

= During Post-ventilation2

Day of the week

19

Burner On

fig. 2 Method A

fig. 3 - Methods B and C

fig. 4 Method A

fig. 5 - Methods B and C