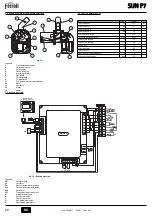

SUN P7

13

EN

cod. 3540I811 - 04/2011 (Rev. 00)

Burner lighting

•

Switch on the power, operating the main switch ahead of the burner.

•

To fill the auger with pellets, see sec. 3.4.

•

close the thermostat line (boiler/room).

Burner setting

1.

Connect a combustion analyser to the boiler outlet and leave the burner working at

max. for 30 minutes; meanwhile, check the efficiency of the flue pipe.

2.

MAKE SURE THE COMBUSTION CHAMBER IS IN NEGATIVE PRESSURE

3.

Check the combustion at max. burner power (adjusted according to boiler nominal

power).

4.

Combustion parameters:

•

O

2

between 5% and 9%

•

CO between 150 and 1000 ppm

To set the burner, change the fan set point by modifying the relevant parameter (see

the section “

Service parameters menu

” and

and table 2

in cap. 2.4).

The CO value depends on the quality of pellets, the amount of dirt in the combustion

head and boiler draught.

To operate the burner in MODULATING mode, it is necessary to modify the param-

eter “

T18

” and then carry out points 5 and 6 described below.

5.

Check the other burner steps, reducing the value of parameter u02 to 1 (see the sec-

tion “

Service parameters menu

” and

table 1

in cap. 2.4).

6.

Set the parameter u02 to the correct value.

4.3 Maintenance

A

Periodically check the cleanness of the burner parts that tend to become dirty

depending on the quality of the pellets or due to poor burner adjustment.

The burner requires periodical maintenance which must be performed by qualified per-

sonnel at least once a year.

The basic operations to carry out are:

•

check and cleaning the internal parts of the burner and boiler as indicated in the fol-

lowing sections;

•

complete combustion analysis (after at least 10 minutes' operation) and check of

correct settings;

Opening of casing and burner disassembly

B

Before carrying out any checking or cleaning inside the burner, disconnect the

power to the burner by means of the main system switch.

To open

Undo the screws (A) and remove the casing (B). The internal components, motor, shut-

ter, etc., can be directly accessed.

To disassemble

Undo the screws (A) and remove the casing (B), undo the nut (C) and disconnect the

body, undo the fixing screws (D) and remove the nozzle (E).

fig. 11

Checks on parts and components

Fan

Make sure no dust has accumulated inside the fan and on the blades: it reduces the air

flow, thus causing pollutant combustion.

Combustion head

Make sure all parts of the combustion head are intact, not warped by the high tempera-

ture, free of impurities coming from the room, and correctly positioned.

Photoresistance

Remove any dust on the glass. The photoresistance is press-on; to remove, pull it out-

wards.

4.4 Troubleshooting

The burner is equipped with an advanced self-diagnosis system. In case of a burner

fault, the display (detail 7 - fig. 1) will flash indicating the fault code.

There are faults that cause permanent shutdown (marked with the letter

"A"

): to restore

operation, press the button

"P"

(detail 5 - fig. 1) for 1 second; if the burner fails to start,

it is necessary to firstly eliminate the fault.

Other faults (indicated with the letter

"F"

) cause temporary shutdowns that are automat-

ically reset as soon as the value returns within the burner's normal working range.

Table. 3 - List of faults

5. TECHNICAL DATA AND CHARACTERISTICS

5.1 Dimensions

fig. 12

A

C

D

E

B

Code

Fault

Cause

Cure

A01

No ignition shut-

down

Pellet container empty

Fill the container with pellets

Auger cable broken or disconnected

Restore the connection

Faulty igniter resistance

Replace and empty the head of pellets

Combustion head dirty

Empty and clean it

Pellet feed duct blocked

Free it, make sure the combustion head is

not clogged and empty it if necessary

F02

Parasite flame

elimination

The demand for heat has ended, but the

burner detects flame

Wait for end of post-ventilation

A02

Shutdown for par-

asite flame

Photoresistance short circuit

Replace the photoresistance

Extraneous light strikes the photoresist-

ance

Eliminate the light source

A04

Auger safety ther-

mostat shutdown

Incorrect ignition parameters

Check the transparent parameters 03=51

and 04=12

Boiler under pressure

Clean it and check correct minimum flue

draught (10Pa)

Faulty safety thermostat

Replace it

F05

Incorrect pipe

pressure adjust-

ment

Pressure sensor connection tube

squashed

Replace

Fan motor damaged

Replace

Fan dirty

Clean it

F06

Pressure trans-

ducer fault (dis-

connected)

Wiring disconnected

Check the wiring or replace the sensor

F10

Boiler shell probe

fault (if enabled)

Sensor damaged

Check the wiring or replace the sensor

Wiring shorted

Wiring disconnected

454

253

315

Ø 139

218

288

Ø 60

162

Ø190