0101-8292-0, Rev. C

3-1

CV-12SLX User Manual

3

Power Supply Operation

3.1 Section Overview

This section covers the following topics:

Section 3.2 HVPS Front Panel Controls and Indicators

Section 3.3 Switches and LEDs on the FPS Front Panel

Section 3.4 Power-Up Procedure

Section 3.5 Control of Power Supply from a TemEBeam Controller (EBC)

Section 3.6 Control of Power Supply by a PLC-Based System Controller

Section 3.7 Responding to Latching Power Supply Faults

3.2 HVPS Front Panel Controls and Indicators

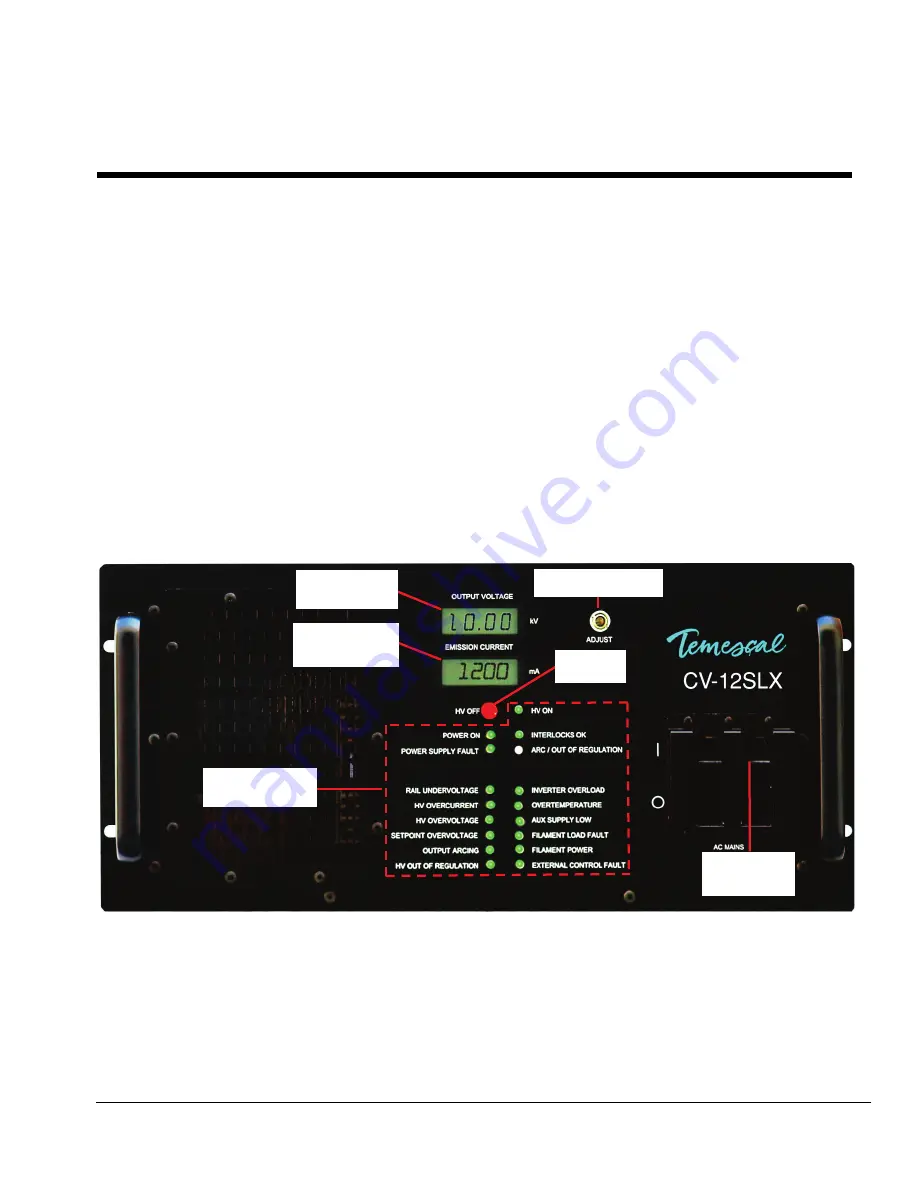

Figure 3-1 shows the controls and indicators on the front panel of the CV-12SLX HVPS. Those

features are described in detail below.

Figure 3-1 CV-12SLX HVPS Front Panel

3.2.1 HVPS Front Panel Controls

Main Circuit Breaker Switch (Labeled

AC MAINS)

High-Voltage Adjustment Pot (labeled

ADJUST

)

HV OFF

Button. This button is always active when the HVPS is powered up. Note that pushing it

when the HV is on switches it off, and pushing it when the HV is off due to a latched fault

condition resets the power supply.

Status and Fault

Indicator LEDs

HV Adjustment Pot

Main Power

Breaker

HV OFF

Button

High Voltage

Meter

Emission

Current Meter