MACHINES AND

ACCESSORIES

Page 22 of 26

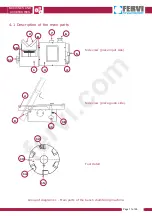

9 MAINTENANCE

9.1 Routine maintenance

Electric shock

Before any inspection or maintenance, turn off the machine and ALWAYS remove the plug

from the power socket. This is to prevent the risk of electric shock.

Clean and take care of the machine regularly to ensure perfect efficiency and a long lifespan.

Using a compressor, regularly blow away the powder and processing residue produced by

chamfering that accumulates on the machine.

Working with compressed air

ALWAYS wear eye protection when using compressed air.

To clean the machine body and other external parts, use a cloth dampened with warm water

only.

Cleaning the machine

DO NOT use detergents or any solvents as plastic parts are easily damaged by chemical

agents.

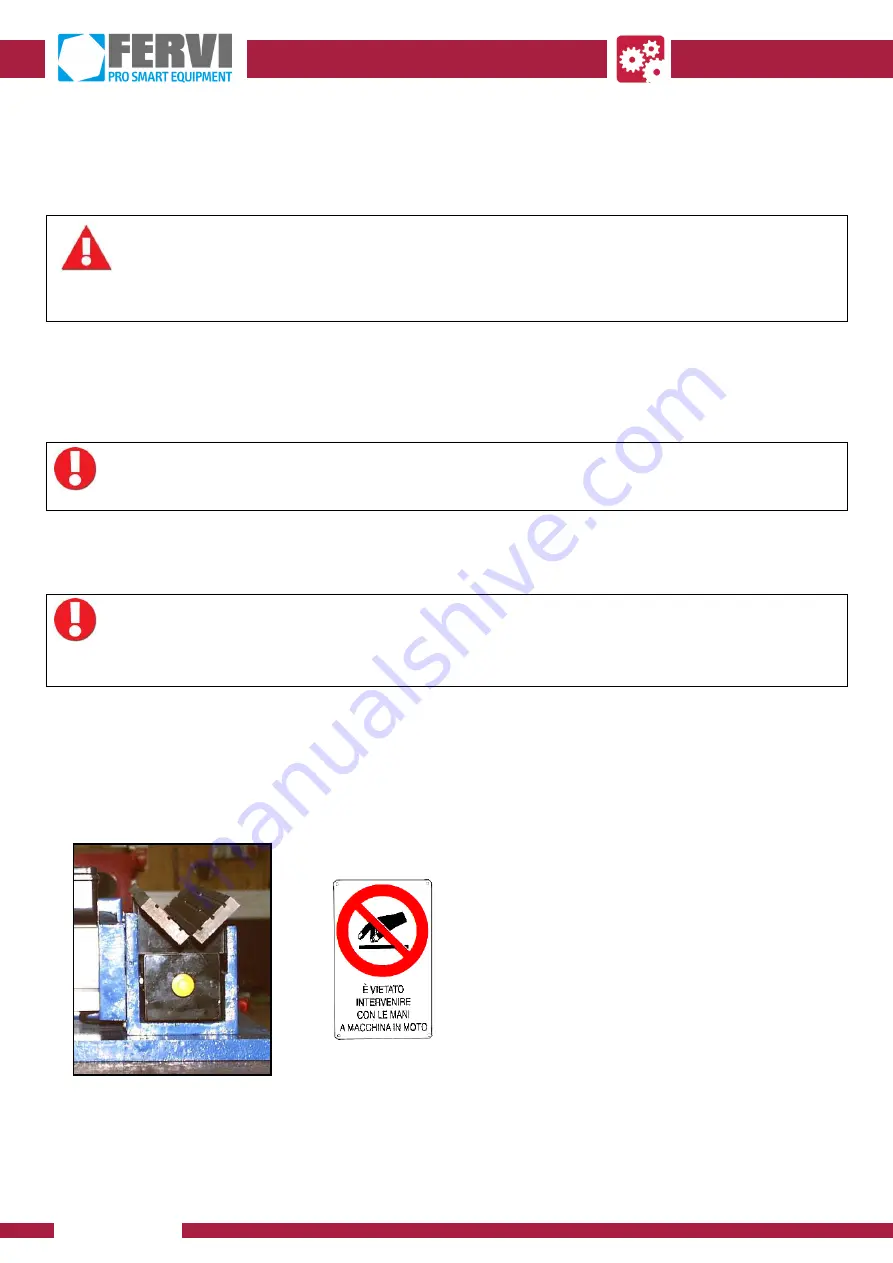

Take care when emptying the filing collection drawer (see Figure 7) as after pulling

the drawer out completely, the milling cutter can be reached through the opening

where the drawer is inserted.

When emptying the drawer pay attention to the warning pictogram (Figure 11).

DO NOT PERFORM ANY INTERVENTION

ON THE MACHINE BY HAND WHEN THE

MACHINE IS RUNNING

Figure 7 – Filing collection drawer.

Furthermore,

every 6 months of life

of the machine, perform a thorough check of operation

and wear; lubricate the rotating tool holder shaft with oil.

fervi.com

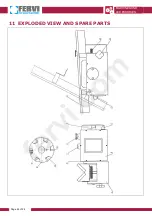

Summary of Contents for 0560

Page 1: ...USE AND MAINTENANCE MANUAL Bench chamfering machine Art 0560 ORIGINAL INSTRUCTIONS fervi com ...

Page 24: ...MACHINES AND ACCESSORIES Page 24 of 26 11 EXPLODED VIEW AND SPARE PARTS fervi com ...

Page 26: ...MACHINES AND ACCESSORIES Page 26 of 26 12 DIAGRAM OF THE ELECTRICAL CIRCUIT fervi com ...