Summary of Contents for 0560

Page 1: ...USE AND MAINTENANCE MANUAL Bench chamfering machine Art 0560 ORIGINAL INSTRUCTIONS fervi com ...

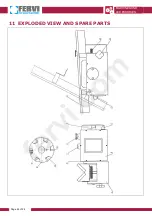

Page 24: ...MACHINES AND ACCESSORIES Page 24 of 26 11 EXPLODED VIEW AND SPARE PARTS fervi com ...

Page 26: ...MACHINES AND ACCESSORIES Page 26 of 26 12 DIAGRAM OF THE ELECTRICAL CIRCUIT fervi com ...