HARDWARE

Page 11 of 13

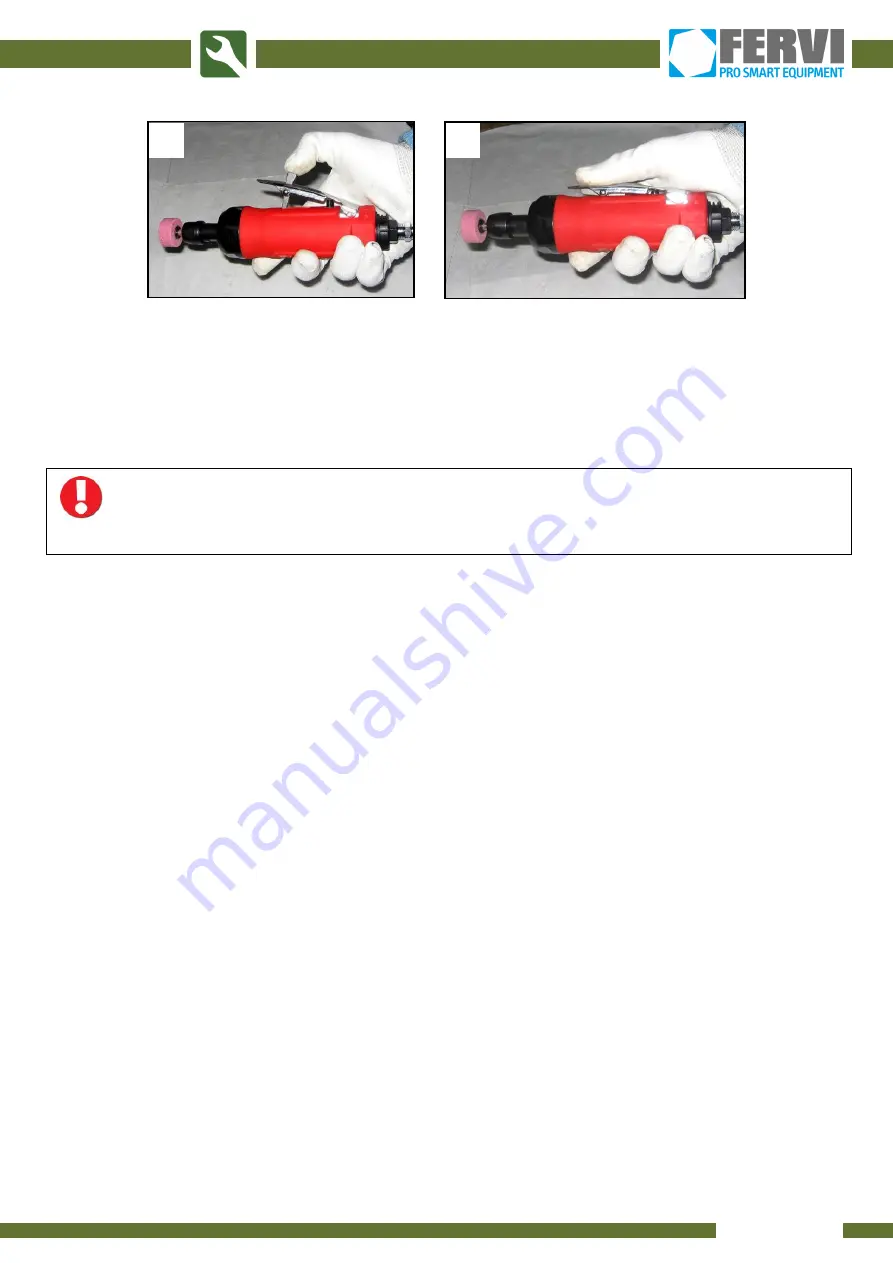

Figure 7 – Turning on the grinder (A: disabling the safety – B: press the lever).

The grinder's start lever is a continuous hold lever, in the sense that the function controlled

(i.e., the rotation of the grinding wheel) is active as long as the lever itself is kept pressed.

Therefore, release the lever to shut it down in an emergency.

Emergency

In case of an emergency, immediately release the grinder's power lever.

Disconnect the air hose and turn off the tool in the event of the following:

to replace the wheels;

to clean, rebuild or perform maintenance on the grinder;

if the grinder is not used for some time.

A

B

fervi.com