HARDWARE

Page 14 of 16

6 MAINTENANCE AND CLEANING

The purpose of this chapter is to provide all the information on maintenance procedures and

the frequency required for the

Air impact wrench.

INTERVENTION

Frequency

Daily

Weekly

1. General visual inspection

X

2. General cleaning

X

3. Clean the air outlet nozzle

X

4. Lubricate moving parts

X

1.

General visual inspection:

check the overall condition of the pneumatic tool,

particularly for any damaged or missing parts. Also check for the presence and

legibility of plates.

2.

General cleaning:

cleaning is necessary to rid the body of oil deposits, dust or dirt

accumulation.

Risks associated with cleaning

Disconnect the air supply hose and clean the body of the tool. Do not use organic solvents to

avoid corrosion or discolouration.

3.

Clean the air outlet nozzle:

cleaning is necessary to free the hot air outlet nozzle

and filter of dirt accumulation. Do not use paint thinner, gasoline, or similar substances

to clean the nozzle.

4.

Lubricating moving parts:

lubricate all the gears and moving mechanical parts of the

wrench, at least once a day, as described below:

a. Insert lubricating oil inside the compressed air inlet nozzle (Figure 8 / B).

To do this, disconnect the air hose, turn over the wrench and put a few drops of

oil into the nozzle using an oiler.

b. Insert lubricating oil inside the housing of the accessory (Figure 8 / A).

To do this, unscrew the hex screw located on the side of the casing, rest the tool

on a horizontal surface, and then insert the oil using an oiler.

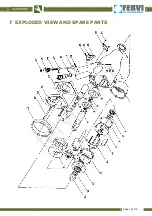

Figure 8 – Lubricating the tool.

A

B

fervi.com