Servo motor

EMMS-AS-140-L…

Festo AG & Co. KG

Postfach

D-73726 Esslingen

+49 711 347-0

www.festo.com

Operating instructions

8002929

1205b

Original: de

EMMS-AS-140-L…

English

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note

Installation and commissioning may only be performed in accordance with these

instructions by technicians with appropriate qualifications.

Additional measures are necessary if used in safety relevant applications, e.g. in

Europe the standards listed under the EC machinery directive must be observed.

Without additional measures in accordance with statutory minimum require-

ments, the product is not suitable for use in safety-related sections of control

systems.

• Please note that the configuration of the EMMS-AS can be determined based

on the rating plate. Depending on the order, this motor contains a holding

brake (EMMS-…-RS

B

/RM

B

/RR

B

) and either an encoder (EMMS-…-R

S

…/R

M

…)

or a resolver (EMMS-…-R

R

…).

Electrostatic discharges onto the motor of more than 3.2 kV can sporadically

result in malfunctions of the motor.

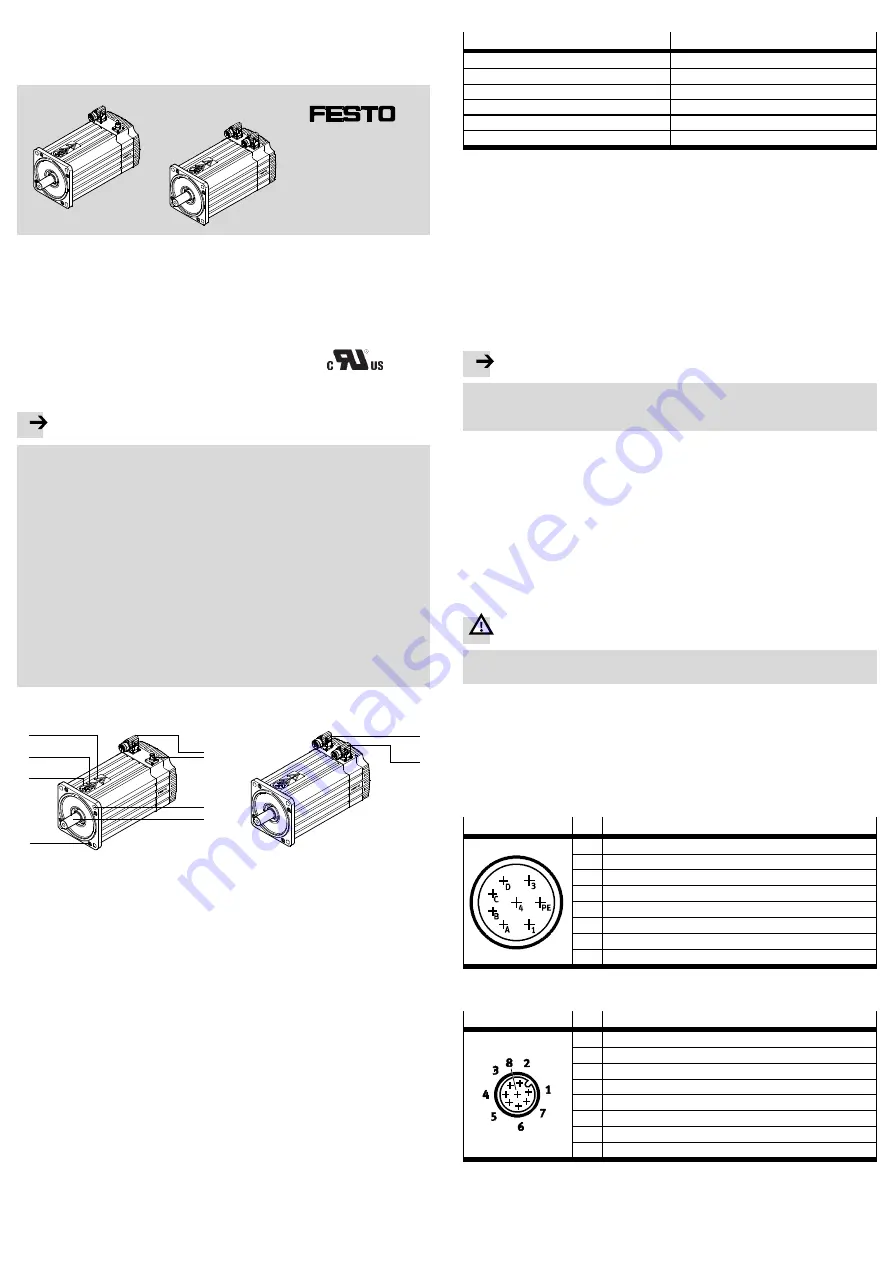

Control sections and connections

Motor with encoder

Motor with resolver

1

2

3

4

5

7

6

8

9

aJ

1

Plug for connecting cable:

– Motor

– Holding brake (only for RS

B

/

RM

B

)

– Temperature sensor

2

Plug for connecting cable:

– Encoder

3

Holes for mounting

4

Shaft

5

Motor flange

6

Note: Mechanical stops are not

permitted

7

Warning - hot surface!

8

Warning - dangerous electric

voltage

9

Plug for connecting cable:

– Motor

– Holding brake (only for RR

B

)

– Temperature sensor

aJ

Plug for connecting cable:

– Resolver

Fig. 1

1

Function and application

The EMMS-AS is a permanently excited, electrodynamic, brushless servo motor.

The EMMS-AS is factory-fitted with an encoder or a resolver depending on the

order code.

The encoder supplies motor data, speed and position signals to a higher-order

controller in the form of digital signals.

The resolver supplies an analogue signal to a higher-order controller; this signal

allows the controller to ascertain speed and position information.

The motor must always be operated within its permitted characteristic curves.

The EMMS-AS is available with the following options:

EMMS-AS-…

Option

…-R

S

/R

S

B

Single-turn encoder for position monitoring

…-R

M

/R

M

B

Multi-turn encoder for position monitoring

…-R

R

/R

R

B

Resolver for position monitoring

…-RS

B

/RM

B

/RR

B

Holding brake

…-

S1

Protection class IP65 (rotary shaft seal)

1)

EMGA (

Accessories)

Gear units

1)

Radial shaft seals are contacting seals and are generally subject to wear. For more detailed information

please visit the Festo Support Portal (

www.festo.com).

Fig. 2

Servo motor EMMS-AS has been designed for driving positioning systems. The holding

brake of the EMMS-AS-…-RS

B

/RM

B

/RR

B

is

not

suitable for braking the motor.

2

Transport and storage

• Ensure storage conditions as follows:

– Storage times should be kept to a minimum

– cool, dry, UV and corrosion resistant (

Technical data)

• Take into account the weight of the EMMS-AS.

Depending on the design the EMMS-AS can weigh over 17 kg.

3

Requirements for product use

Note

Improper handling can result in malfunctions.

• Make sure that the specifications contained in this chapter are adhered to at

all times.

• Compare the maximum values specified in these operating instructions with

your actual application (e.g. forces, torques, masses, speeds, temperatures).

The use of force to move the motor shaft will reduce the functionality of an op-

tional integrated holding brake.

• Ensure that all applicable safety regulations are adhered to, e.g. from trade

associations or national authorities.

• Use the EMMS-AS in its original state. Unauthorized product modification is not

permitted.

• Take into account the prevailing ambient conditions at the location

(

Technical data).

4

Installation

Warning

Open cable ends on the rotating motor can, under certain circumstances, lead to

dangerous high voltages.

1. First leave the motor decoupled from the driven mechanical component.

2. Make sure that the controller is switched off.

Cancelling the Controller Release signal is not sufficient.

3. Connect the EMMS-AS completely to the controller as shown in the following

tables. Pre-assembled cables from Festo (

Accessories) offer sufficiently large

cable cross-sections as well as screening of the motor/encoder/resolver cable

with an earth contact on both sides.

4.1 Motor with encoder

Power plug

Pin

1

Motor, holding brake, temperature sensor

1

Phase U

PE

Protective earth

3

Phase W

4

Phase V

A

Temperature sensor M

T–

(PTC)

B

Temperature sensor M

T+

(PTC)

C

Holding brake BR+

1)

D

Holding brake BR–

1)

1)

Only for motors with holding brake EMMS-AS-…-RS

B

/RM

B

Fig. 3

Signal plug

Pin

2

Encoder

1

0 V

2

UP

3

DATA

4

DATA/

5

0 V

6

CLOCK/

7

CLOCK

8

UP

Fig. 4