Summary of Contents for 530411

Page 2: ......

Page 4: ...Contents and general instructions II Festo P BE MPA EN en 1108e ...

Page 16: ...Contents and general instructions XIV Festo P BE MPA EN en 1108e ...

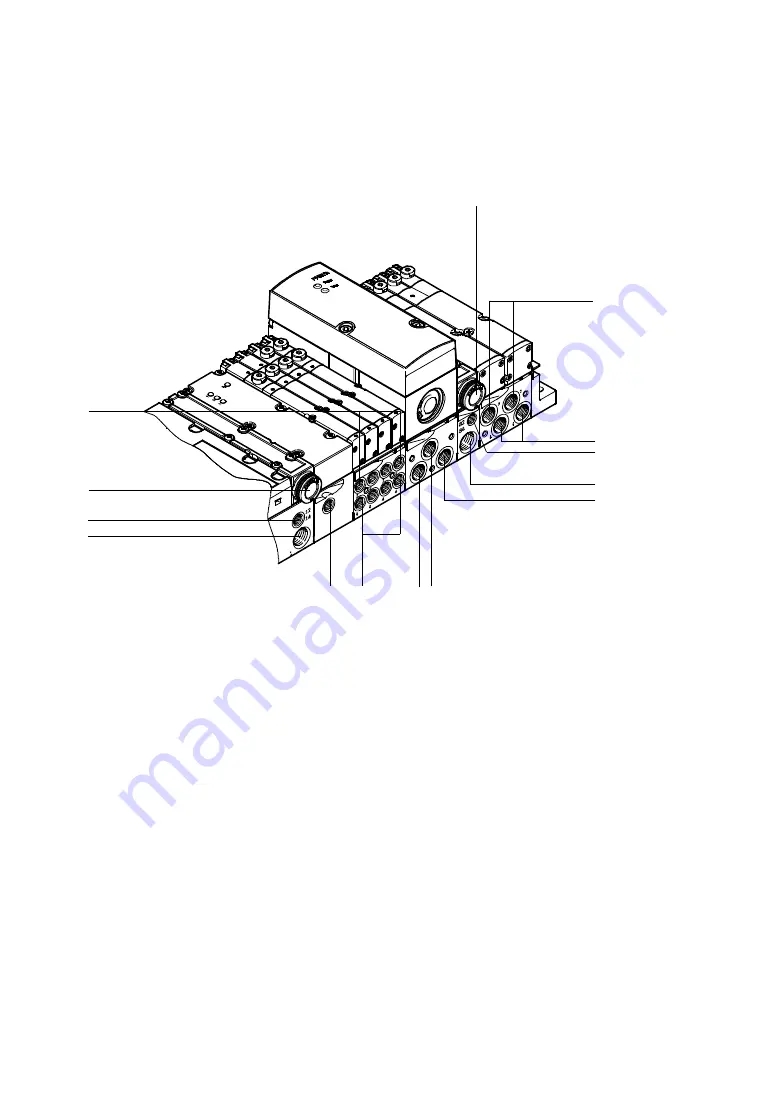

Page 17: ...Summary of components 1 1 Festo P BE MPA EN en 1108e Chapter 1 Summary of components ...

Page 59: ...Fitting 2 1 Festo P BE MPA EN en 1108e Chapter 2 Fitting ...

Page 73: ...Installation 3 1 Festo P BE MPA EN en 1108e Chapter 3 Installation ...

Page 108: ...3 Installation 3 36 Festo P BE MPA EN en 1108e ...

Page 109: ...Commissioning 4 1 Festo P BE MPA EN en 1108e Chapter 4 Commissioning ...

Page 172: ...5 Maintenance and conversion 5 42 Festo P BE MPA EN en 1108e ...

Page 173: ...Technical appendix A 1 Festo P BE MPA EN en 1108e Appendix A Technical appendix ...

Page 209: ...Index C 1 Festo P BE MPA EN en 1108e Appendix C Index ...

Page 210: ...C Index C 2 Festo P BE MPA EN en 1108e Contents C Index C 1 ...