© Festo Didactic 746310

29

•

Do not disconnect tubing while under pressure.

•

Danger of accident due to tubing slipping off!

– Use shortest possible tubing connections.

– Wear safety glasses.

Immediately deactivate compressed air supply if the tubing slips off.

•

Pneumatic circuit setup:

Connect the devices using plastic tubing with an outside diameter of 4 or 6 mm. Push the tubing into the

push-in connector as far as it will go.

•

Switch compressed air supply off before dismantling the circuit.

•

Dismantling pneumatic circuit:

Press the blue release ring down, after which the tubing can be pulled out.

5

Work instructions

Process engineering

•

The lower tank may only be filled when supply power is switched off!

•

Switch 24 V DC power supply off and disconnect the power supply unit from 230 V DC power.

•

Use drinking water (recommended), which ensures long-term, maintenance-free operation of the

system.

•

The maximum permissible operating temperature of +65° C for the tank may not be exceeded.

•

The maximum permissible operating pressure of 0.5 bar for the liquid in the tubing may not be

exceeded.

•

The pump must not be allowed to run dry. The pump may not be used with seawater, contaminated

liquids or viscous media.

•

Empty the liquid from the system by opening the drain valve after completing experiments or before

changing the piping layout.

•

Inspect the liquid and replace it at least once a week if contaminated.

•

Clean the system as required, but in any case at least once a week. Do not use aggressive cleansers or

scouring agents.

•

The liquid ages if the system is left at a standstill for a lengthy period of time. Always empty the tanks

and the piping before leaving the system at a standstill for any length of time.

•

No liquids may be permitted to remain within the system for long periods of time, because this may

result in the growth of bacteria such as so-called legionellae.

Pneumatics

•

Set system pressure to a value within a range of 300 to 600 kPa (3 to 6 bar) for operation of the 2-way

ball valve with pneumatic quarter-turn actuator.

Summary of Contents for 746310

Page 4: ...Festo Didactic 746310...

Page 6: ...6 Festo Didactic 746310...

Page 13: ...Festo Didactic 746310 13 Montageschritt 3 6 Oberer Tank...

Page 26: ...26 Festo Didactic 746310...

Page 33: ...Festo Didactic 746310 33 Assembly step 3 6 Upper tank...

Page 46: ...46 Festo Didactic 746310...

Page 53: ...Festo Didactic 746310 53 Paso de montaje 3 6 Dep sito superior...

Page 66: ...66 Festo Didactic 746310...

Page 73: ...Festo Didactic 746310 73 tape 3 6 Cuve sup rieure...

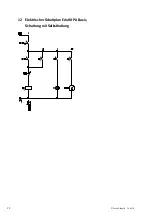

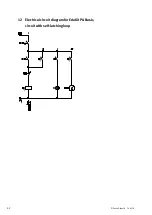

Page 82: ...82 Festo Didactic 746310 12 Sch ma lectrique de l EduKit PA Basic montage automaintien...