Assembly instructions (original: de)

8004745

1301NH

†‡

Motor cable

NEBM-M16G8-E-...-Q9-LE8

Festo AG & Co. KG

P.O. box

73726 Esslingen, Germany

+49 711 347-0

www.festo.com

1.

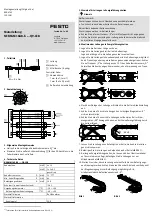

Parts list

18366d_1

1

Cable

Motor side:

2

M16 socket (8-pin)

Controller side:

3

Wire end sleeve

7 mm (4x 1.5 mm²)

7 mm (2x 2x 0.5 mm²)

4

Outside

screen

connection

2.

Pin allocation

18366d_2

18367d_3

1

3.

General assembly instructions

Observe the permissible tightening torques M

A

1)

.

Clamp the external screen connection

4

for the PE connection into the

spring clip of the controller.

4.

Technical data

NEBM-M16G8-E-...-Q9-LE8

Cable composition

[mm²]

4x 1.5

[mm²]

2x 2x 0.5

screened

Cable diameter

D

[mm]

12

+0.80

−

0.75

Min. cable bending radius

R

[mm]

64

Mounting space

A

[mm]

240

Protection class (in mounted status)

IP 65

Ambient temperature

[°C]

−

50

…

+90

With flexible cable installation

[°C]

−

40

…

+90

Note on materials

RoHS-compliant

Information on materials

Cable

sheath

Polyurethane

(PUR)

1)

Tolerances for non-toleranced tightening torques M

A

± 20%

5.

Instructions for cables in energy chains

Note

If there is a chain break:

The cables can be damaged due to overstretching.

Replace all the cables after a chain break.

With a vertically hanging chain array:

The cables will stretch during operation.

Ensure that there is more clearance “X” than specified in assembly step 3.

Check the length of the cables after a short operating period and adjust, if

necessary.

6.

Mounting the cables in energy chains

1.

Lay the chain out lengthwise.

2.

Place the cables in the chain studs, making sure they are not twisted.

Lay out or hang the cables first, if necessary.

3.

Lay the cables loose next to each other in the chain studs, if possible

separated from each other by separators or separate holes. Ensure the

clearance “X” of the cables is 10% of the cable diameter “D”. Avoid plac-

ing cables on top of each other without use of separators.

7435d_3

4.

After laying the cables, adjust the chain in the working position.

5.

Make sure that the bending radius of the cables is not smaller than the

permitted bending radius “R”.

6.

Make sure that the cables can move freely in the bending radius “KR”; the

cables must not be forced through the chain.

7435d_4

7.

Leave the cables loose in the chain; do not tie them together.

8.

Fasten the cables at both ends of the chain (

Fig. 1).

9.

With long energy chains in which the upper run lies on the lower run, fas-

ten the cables only at the driver end (

Fig. 2).

10.

Make sure that the cables are on no account moved all the way to the

fastening point. Make sure the distance between the end point of the

bending movement and the attachment is as large as possible

but at least equal to mounting space “A”.

Fig. 1

7435d_2

Fig. 2

7435d_1

M

A

= 0.4 Nm

1

3

2

2

4

2

KR

›

R