Job Sheet 3 – Variable-Speed Belt Drives

© Festo Didactic 54977-3C

43

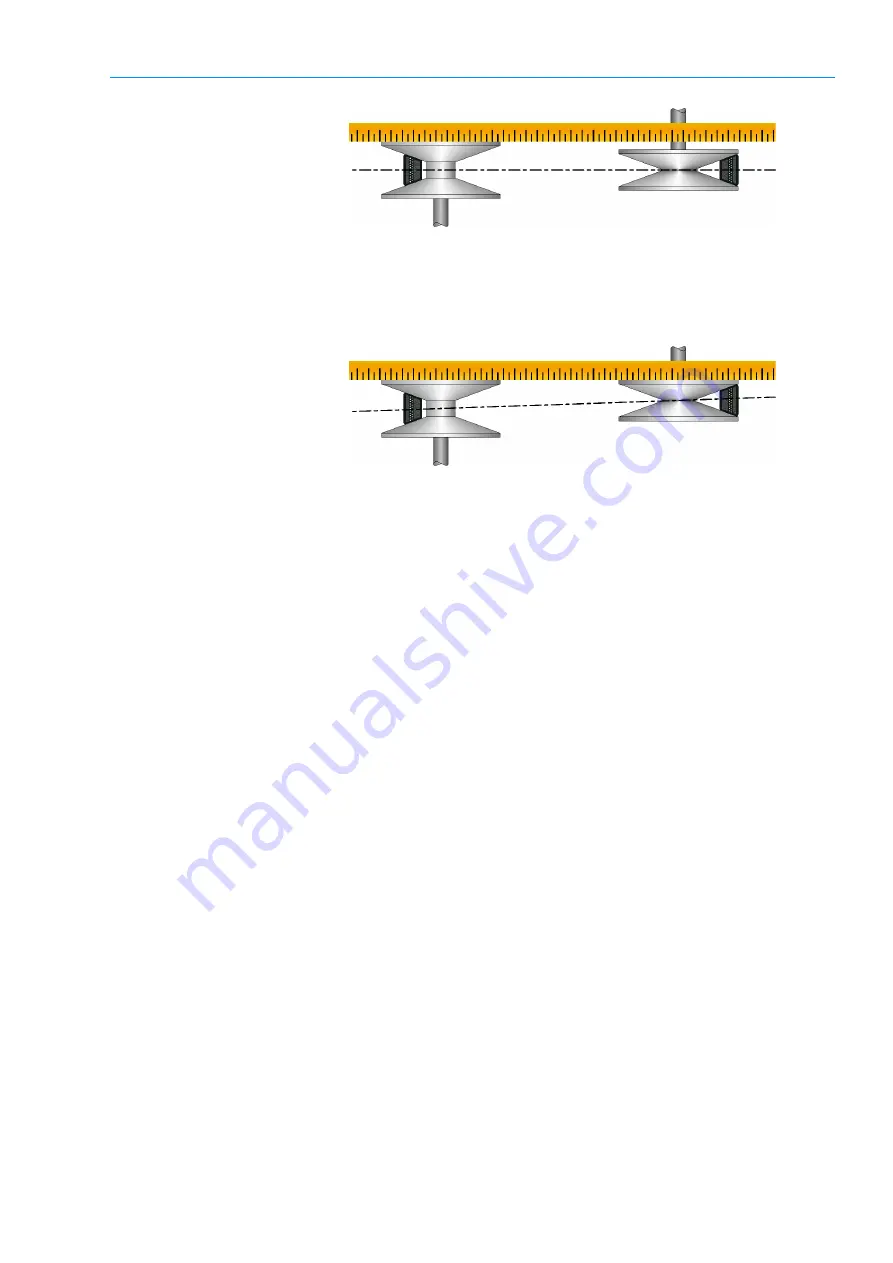

Figure 35. Correct variable-pitch pulleys alignment.

Figure 36 shows what happens when you try to align pulleys with different widths

using the conventional method. Because the distance between the straightedge

and the running center is not the same on each pulley, the belt is misaligned.

Figure 36. Incorrect variable-pitch pulleys alignment.

Variable-pitch pulley maintenance

Variable-pitch pulleys often require lubrication because of the friction between

the flanges and the threaded hub. Excessive lubrication must be avoided since it

can result in premature wear and component failure. Operating the pulley in one

position for an extended period of time may also cause premature wear of the

components. This makes the shifting of position more difficult. When the

variable-pitch pulley has one fixed flange, the alignment of the belts may be

influenced due to the shifting of the belt up or down the pulley groove. It is,

therefore, preferable to align the pulleys in a position that minimizes the side

wear of the belt. It is also recommended to prevent the surface of the belt to

make contact with the bottom surface of the pulley, where the threaded hub is

located.

Summary of Contents for Belt Drives 2

Page 1: ...Industrial Maintenance Belt Drives 2 Course Sample 54977 3C ...

Page 6: ......

Page 10: ......

Page 12: ......

Page 13: ...Sample Extracted from Job Sheets Instructor ...

Page 14: ......

Page 22: ......