CESA-GW-AS-PB Description

26

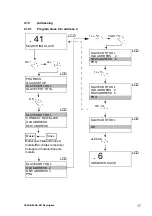

6.2

Navigating through the advanced display mode

The device starts up in the classical mode. Pressing the OK button switches to

the advanced mode. To return to the classical mode, the ESC button must be

pressed several times.

In the advanced mode, the selection menu can be moved up and down by using

the two arrow buttons. Pressing OK switches to the selected function or to the

displayed menu, respectively. Pressing ESC returns to the previous menu.

To edit a value it must be highlighted by using the selection bar and then press-

ing OK. The data can be changed by using the arrow-buttons. Changes are con-

firmed with OK. The ESC button cancels the editing process.

All possible slave addresses are displayed in sequence from 1 A to 31 A and

from 1 B to 31 B. Data for single slaves are displayed along with the addresses

1 A to 31 A.

Warning!

Classical (traditional) mode does not guarantee any protection of the settings of the

device!

In the classical mode, it is possible to change settings while the device is in operation.

This can lead to failures of the installation/process (for example changing the address

of an AS-i slave).

1.12A

PROFIBUS

AS-I CONTROL

QUICK SETUP

SLAVE ADR. TOOL

SLAVE TEST TOOL

SETUP

IO + PARAM.TEST

DIAGNOSIS

DISPLAY CONTRAST

ADV. DIAGNOSE

AS-I SAFETY

LANGUAGE

DISPLAY CONTRAST

Information!

Some of the settings in the advanced mode are protected as long as the upstream

fieldbus running. That means that some status information can be displayed only.

To protect the installation/process, many options such as "change address", "write

parameter", "set outputs", etc. cannot be performed with an active connection to the

control system (active PROFIBUS masters Class 1Bus connection) . In order to exe-

cute these commands via the display, the connection to the control system must be

deactivated first (no PROFIBUS Master Class 1 connection).

Summary of Contents for CESA-GW-AS-PB

Page 1: ...Description AS i Gateway English Gateway AS i PROFIBUS CESA GW AS PB 749962 1002NH ...

Page 2: ......

Page 4: ......