DNCKE−...−S / KEC−...−S

Festo DNCKE−...−S / KEC−...−S 1002a English

36

S

Place the clamping unit in the intended position.

S

Turn the mounting screws until they are equally tight.

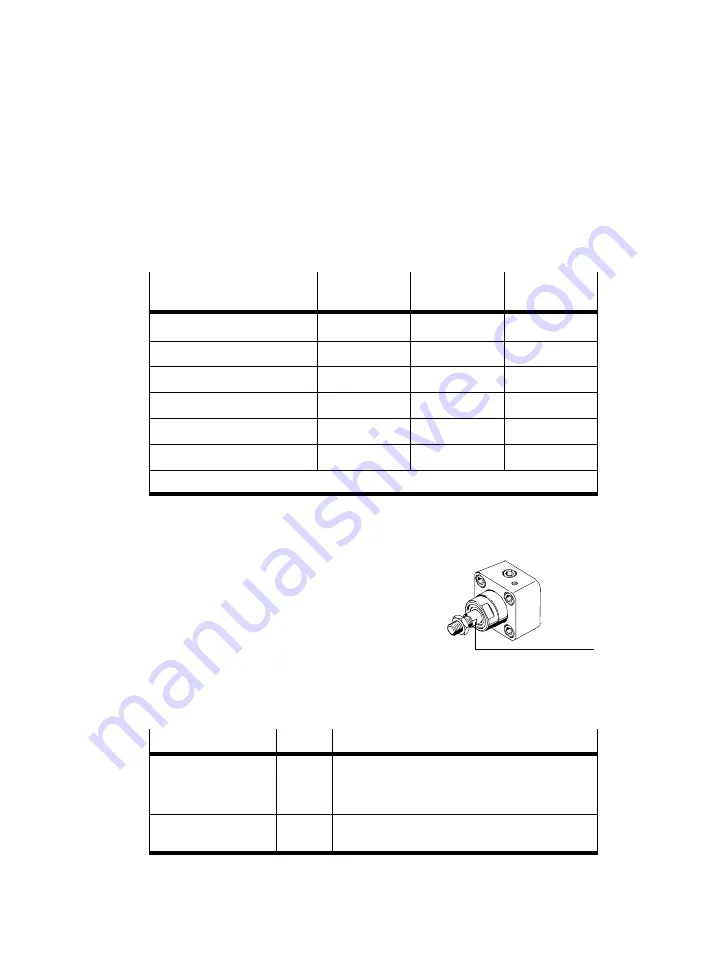

The tightening torques are listed in the following table:

Type

DNCKE−/

KEC−40−...

DNCKE−/

KEC−63−...

DNCKE−/

KEC−100−...

L1 [mm]

*)

178

208.5

287

ZJ+ [mm] (plus stroke length)

277

315

408

TG [mm]

38

56.5

89

E [mm]

54

80

126

Tightening torque

5 Nm

8 Nm

10 Nm

Nominal size

M6

M8

M10

*) Dimension varies depending on setting of the adjusting screw

Fig.6

Fitting the work load onto the cylinder with clamping unit DNCKE−...:

S

Fasten the work load to the piston rod.

The spanner flat

aJ

on the piston rod

serves as a counter holder for the lock

nut.

If necessary, secure the lock nut with a

thread locking agent.

Installing the pneumatic system

S

Check whether the following accessories are required:

Designation

Type

Function

Non−return valves

HGL−...

− slow pressure reduction with loss of

−

compressed air

− redundancy with stop function"

Compensation reser

voir

VZS−...

Reducing pressure fluctuations in the

following compressed air string

Fig.8

Fig.7

DNCKE−...

aJ