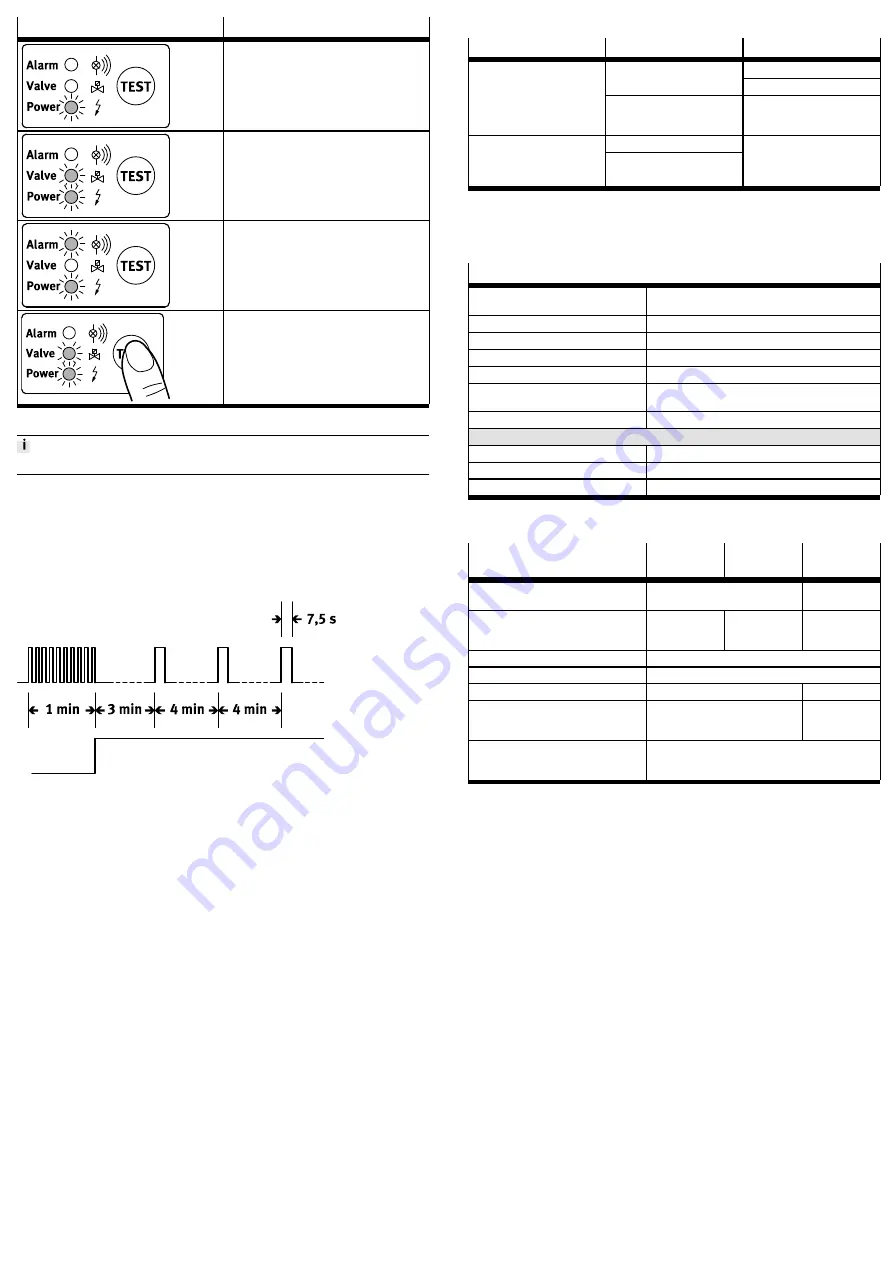

Operating status LEDs

Function

Ready for operation Voltage is present

Drain sequence Feed pipe is open

Malfunction/alarm

If there is a malfunction in the condensate drain,

the valve opens in cycles (approx. every 3 s) so

that the malfunction can be automatically

remedied.

Test of valve function (manual draining):

Actuate the pushbutton for approx. 2 s. Test of

alarm function

è

Alarm mode function: Actuate

the pushbutton for at least 1 minute.

Tab. 8 Operating status LEDs

Do not use the test pushbutton for continuous draining.

Alarm mode function

The PWEAAC/AP condensate drain also has an alarm mode function for malfunc

tions when draining the condensate. If the sensor is not free after 1 minute, a fault

message is triggered.

–

An alarm LED flashes.

–

An alarm relay switches. The signal can be transmitted potentialfree.

–

The valve opens every 4 minutes for 7.5 s.

Fig. 7

If the malfunction is remedied, the PWEAAC/AP condensate drain automatically

switches back to normal mode.

Potential-free fault message contact

The alarm signal can be forwarded via the potentialfree contact (e.g. to a control

station). The switching contact can, for example, be operated in failsafe mode.

–

The PWEAAC/AP condensate drain works faultfree when powered

è

The

alarm relay is activated.

–

If there is no operating voltage or if there is a fault message, the alarm relay

switches off

è

The working contact is open (alarm).

External test

Any existing condensate can be drained via remote control. The normal test push

button function also leads out of the PWEAAC/AD condensate drain here. If the

external contact is closed, the valve opens. The connection can be connected to a

switch, a relay contact or an open collector output.

6

Service

6.1

Cleaning and maintenance

•

Clean the PWEAAC/AP condensate drain, if required, with a soft cloth. Clean

ing agents include all nonabrasive media.

7

Malfunctions

Malfunction

Possible cause

Remedy

Check compressor.

Blocked drain pipe

Clean supply line.

Minimum pressure not reached

Error in the installation.

Perform installation in accord

ance with the instruction manu

al.

Overload

Condensate is too high

Extremely large quantities of

dirt particles

Observe maximum permissible

operating pressure

è

Tab. 9

8

Technical data

8.1

Technical data, pneumatic

Operating conditions

Permissible temperature

range

[°C]

+1 … +60

Operating medium

Compressed air

Operating pressure

[bar]

0.8 … 16

Mounting position

Standing upright ± 5°

Condensate feed

G

½

inside

Condensate drain (tubing)

G¼

@

8 … 9 mm angle nozzle

e.g. type PUNH12x2NT

Weight (empty)

[kg]

0.7

Materials

Housing

Polymer

Condensate reservoir

Al

Seals

NBR, FPM, PU

Tab. 10

8.2

Technical data, electrical

Electrical data PWEA-

AC/-AP

6A

7A

3D

Maximum power consump

tion

P < 2.0 VA

P < 2.0 W

Mains voltage

U

AC

=

115 V ±10 %

50 … 60Hz

U

AC

=

230 V ±10 %

50 … 60Hz

U

0

=

24 VDC

+10 … 25 %

1)

Recommended cable sheath

[

@

]

5.8…8.5 mm

Cable cross section

[mm

2

]

3 x 0.75, 5 x 0.25

Fuse protection

0.5 A

2)

100 mA

1)2)

Contact load / potentialfree

fault message

0 V … 250 V

0 mA … 1000 mA

5 V … 30 V

10 mA … 1000

mA

External test IN1 and 0V

Test active:

Test inactive:

IN1: 0 … 1 V contact closed

IN1: 5 … 36 V contact open

1) Minimum voltage source internal resistance Ri 12 Ohm

2) medium timelag

Tab. 11