5. Diagnosis and error treatment

5-8

Festo P.BE-SPC11-SYS-ASI-EN en 0203NH

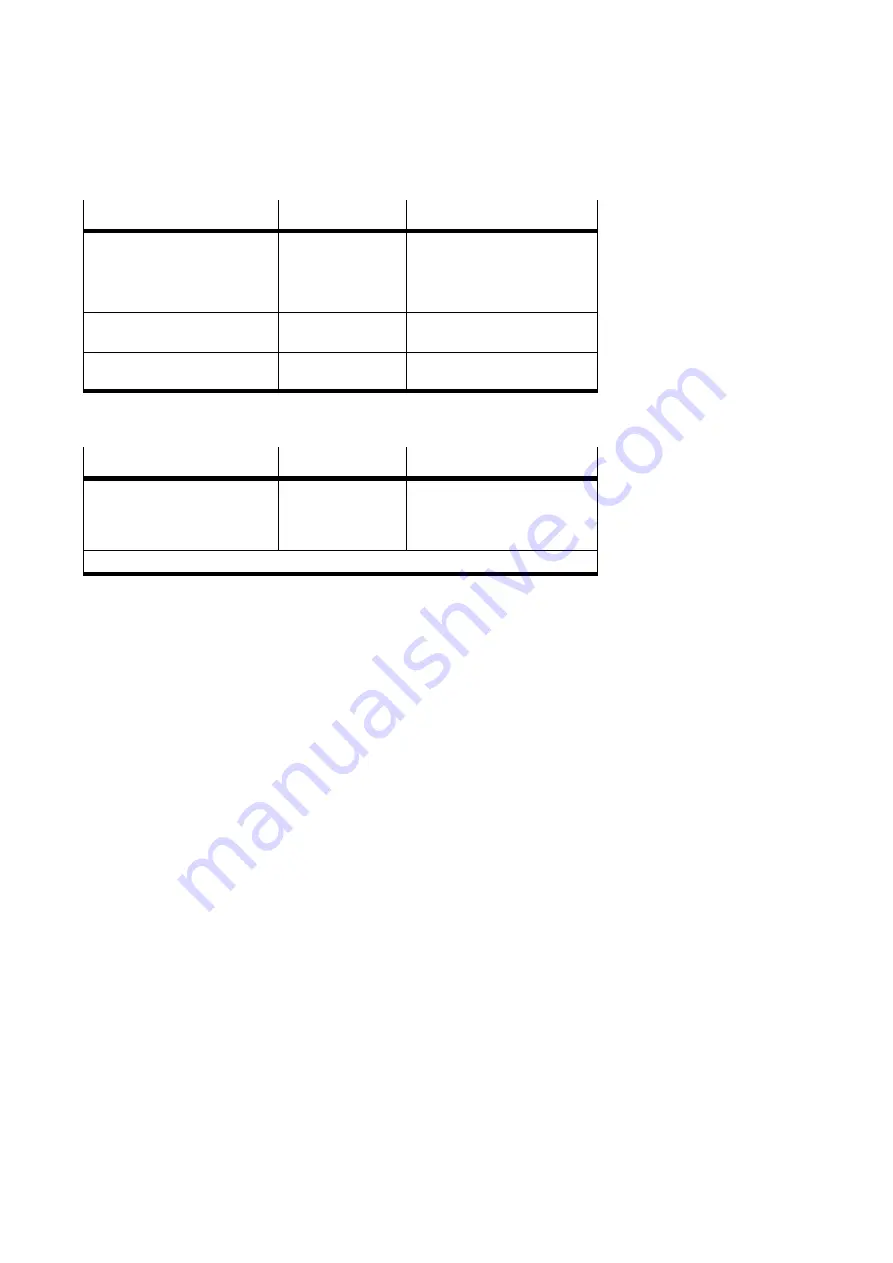

Cause

Remarks

Remedy

The mechanical end positions have

shifted

Check the stability of

the mechanical end

positions

In order that the moveable mass

remains in the taught end position,

it is pressed against the fixed stop

with a pressure equal at maximum

to the operating pressure.

During too fast/hard movement into

the end positions

Increase the cushioning

stage (parameter C)

See section 5.4

During too slow/soft movement into

the end positions

Reduce the cushioning

stage (parameter C)

See section 5.4

3) Slide moves to end position without a command.

Cause

Remedy

Remarks

Proportional directional control

valve is defective

Check and, if necess-

ary, replace propor-

tional directional

control valve

You can check through the viewing

window to see if the valve slide

jams.

1)

1) See operating instructions for valve MPYE-5-...

Summary of Contents for Soft Stop SPC11 Series

Page 2: ......

Page 14: ...Contents and general instructions XII Festo P BE SPC11 SYS ASI EN en 0203NH ...

Page 15: ...Summary of components 1 1 Festo P BE SPC11 SYS ASI EN en 0203NH Chapter 1 ...

Page 25: ...Fitting 2 1 Festo P BE SPC11 SYS ASI EN en 0203NH Chapter 2 ...

Page 28: ...2 Fitting 2 4 Festo P BE SPC11 SYS ASI EN en 0203NH ...

Page 29: ...Installation 3 1 Festo P BE SPC11 SYS ASI EN en 0203NH Chapter 3 ...

Page 61: ...Commissioning 4 1 Festo P BE SPC11 SYS ASI EN en 0203NH Chapter 4 ...

Page 100: ...4 Commissioning 4 40 Festo P BE SPC11 SYS ASI EN en 0203NH ...

Page 101: ...Diagnosis and error treatment 5 1 Festo P BE SPC11 SYS ASI EN en 0203NH Chapter 5 ...

Page 114: ...5 Diagnosis and error treatment 5 14 Festo P BE SPC11 SYS ASI EN en 0203NH ...

Page 127: ...Technical appendix B 1 Festo P BE SPC11 SYS ASI EN en 0203NH Appendix B ...