Pressure sensor SPAN

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions

8049275

1607

[8049280]

Original: de

Pressure sensor SPAN

English

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

Product description

The operating instructions describe the entire function range. The function range is

limited, depending on the product variant.

Note

You can find detailed specifications for the product, the device description file

(IODD) with a description of the IO-Link parameters and the declaration of con

formity at:

è

www.festo.com/sp.

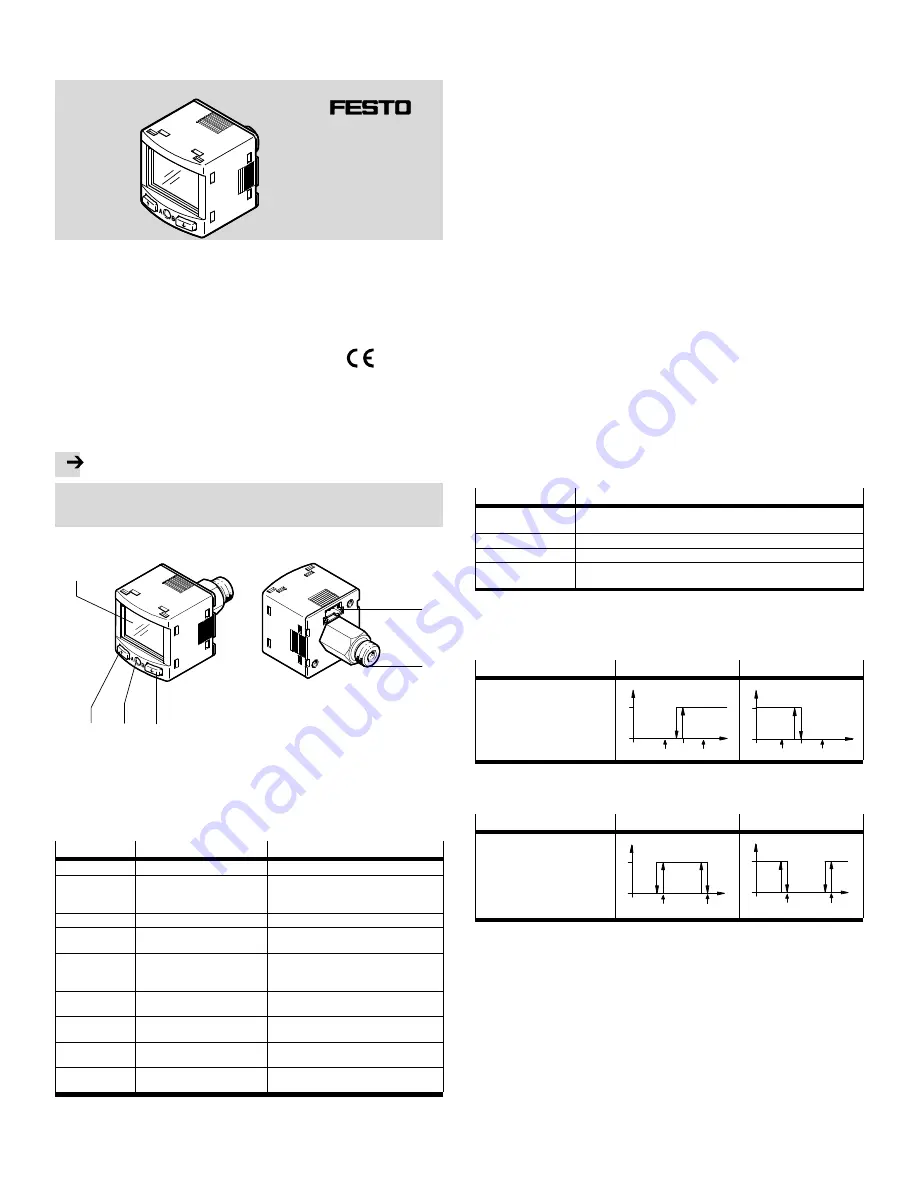

1.1 Overview

1

2

3

4

5

6

1

Display

2

Electrical connection

3

Pneumatic connection

4

B-key

5

Edit button

6

A-key

Fig. 1

Representation of other variants can deviate from this

1.2 Characteristics

Characteristic

Value

Description

Type

SPAN

Pressure sensor

Pressure

measuring range

-B2, -B11, -P025, -P05, -P1, -P2,

-P6, -P10, -P12, -P16, -V025,

-V05, -V1

è

Technical data

Supply port

R

Relative pressure

Pneumatic port

-G18, -R18, N18, -M5,

-Q4,

Thread G

x

, R

x

, NPT

x

, M5

Push-in connector

4 mm

Thread type

M

F

None

Male thread

Female thread

Electrical

output 1

-PNLK

-PN

Switching output PNP / NPN / IO-Link

PNP / NPN

Electrical

output 2

-PNVBA

-PN

PNP / NPN / 0…10 V / 1…5 V / 4…20 mA

PNP / NPN

Electrical

connection

-L1

Plug connector, design L1

Certificate

+T

Without

With inspection report

Fig. 2

2

Safety

Intended use

The pressure sensor SPAN is intended for monitoring pressure of compressed air

and inert gases in the piping.

General safety information

Only use the product in its original status, without any unauthorised modifications.

Only use the product if it is in an excellent technical status.

The product is intended for use in industrial environments. Measures may need

to be implemented in residential areas for radio interference suppression.

Take into consideration the ambient conditions at the location of use.

Operate the product only with compressed air of the specified air quality class

(

è

Technical data).

Observe the specifications on the rating plate.

Comply with all applicable national and international regulations.

Disposal

Observe the local specifications for environmentally friendly disposal.

3

Function and application

The sensor converts pneumatic pressure values (relative pressure) into electrical

signals, which can be used for control or regulating functions.

Measurements are

carried out using a piezoresistive sensor element with a following electronic evalu

ation unit. Interfacing to the higher-level system is provided by 1 or 2 switching

outputs, an optional analogue output and an optional IO-Link interface.

The switching outputs can be configured for monitoring of a threshold value,

a pressure range or a differential pressure. The outputs can be set as PNP or NPN

and normally open (NO) or normally closed (NC). Via the IO-Link interface, process

values can be read out and parameters changed and transmitted to additional

devices.

3.1 Operating statuses

Operating status

Function

RUN mode

– Basic status after the operating voltage is switched on

– Display of the current measured value

SHOW mode

– Display of the current settings

EDIT mode

– Setting or modification of parameters

TEACH mode

– Acceptance of the current measured value to determine switching

points

Fig. 3

3.2 Switching functions

Threshold value comparator for monitoring of a pressure threshold

Function

NO (normally open)

NC (normally closed)

Switching function:

– 1 switching point (SP)

TEACH mode:

– 2 teach-in points (TP1, TP2)

– SP = ½ (TP1+TP2)

TP1 TP2

HY

1

0

Out

p

SP

TP1 TP2

SP

HY

1

0

Out

p

Fig. 4

Window comparator for monitoring of a pressure range

Function

NO (normally open)

NC (normally closed)

Switching function:

– 2 Switching points

(SP.Lo, SP.Hi)

TEACH mode

1)

:

– 2 teach-in points (TP1, TP2)

– TP1 = SP.Lo, TP2 = SP.Hi

HY HY

TP1=SP.Lo TP2=SP.Hi

1

0

Out

p

HY HY

TP1=SP.Lo TP2=SP.Hi

1

0

Out

p

1)

SP.Lo = smaller pressure/vacuum value, SP.Hi = larger pressure/vacuum value, dependent on the

Teach sequence

Fig. 5

Auto difference monitoring d_|¯|_

This funciton permits monitoring of a pressure value for constancy.

If the applied pressure is constant in the range between [SP.Lo] and [SP.Hi], the refer

ence pressure PRef is automatically determined. The result is a switching operation at

the output. The signal change signals the start of pressure monitoring.

If the pressure remains in the monitoring range [d.SP] around PRef, the pressure is

stable. When the monitoring range is left (e.g. caused by a leakage in the system),

the output switches back.