7

Assembly

CAUTION!

Risk of injury due to falling product.

•

Make sure the mounting surface is sufficiently strong to absorb the maximum forces.

•

Only use suitable mounting components.

•

Secure the screw connections.

Observe the information on mounting components in the respective documentation

è

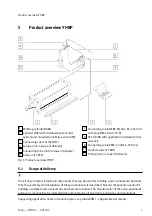

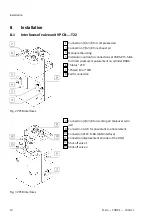

1. Assemble the cylinder DSBG and accessories as follows.

–

Assemble the DSBG backlash-free and free from transverse loads.

–

To prevent friction, ensure parallelism with the guide unit.

–

If possible, use a self-aligning rod coupler to balance the angular and radial backlash.

2. Mount the proximity sensor SMT as a reference sensor to the displacement encoder DNCI. The

proximity sensor is needed for referencing of the displacement encoder. Information on referen-

cing

è

–

Attach the proximity sensor near the lower end position of the DNCI. Tightening torque:

£

0.6 Nm

3. Assemble the displacement encoder DNCI backlash-free and parallel to the cylinder DSBG.

–

There must be a secure connection between the DSBG piston rod and DNCI piston rod.

–

Choose suitable accessories in accordance with the installation situation.

4. Assemble the valve unit VPCB.

5. Connect the valve unit VPCB with the cylinder DSBG. There are two options for this:

–

Connect the valve unit VPCB directly with the cylinder DSBG using a double nipple.

Internal diameter:

³

8 mm

–

Connect the valve unit VPCB with a pipe or a suitable hydraulic hose

£

300 mm with the cylin-

der DSBG.

A connection with the aid of tubing is not permitted.

6. Assemble the control element VAOH in the appropriate place. Tightening torque:

£

10 Nm

7. Assemble the balancer kit CECC-D-BA in accordance with local conditions and in compliance with

the degree of protection.

Assembly

9

Festo — YHBP-1 — 2018-11