< 15%

*

*

Recommendation:

Charge the battery pack

before any further use.

Further information about the battery pack

and charger can be found in the corre

sponding operating manual.

8

Settings

CAUTION

Risk of injury

► Only adjust the settings when the power

tool is switched off.

8.1

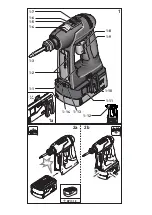

Changing direction of rotation [1-8]

– Switch to the left = clockwise rotation

– Switch to the right = counterclockwise rota

tion

8.2

Changing gear [1-4]

Only actuate the gear switch with the tool

switched off. Otherwise there is a risk of

damaging the gear unit.

• Gear switch forwards (digit 1 visible) =

1st gear

• Gear switch to rear (digit 2 visible) =

2nd gear

8.3

Fastening

Adjust the switch so that its marking

[1-7]

faces the screw symbol

[1-6]

.

Adjust the torque accordingly at the torque

wheel

[1-1]

.

Position 1 = low torque

Position 25 = high torque

An

acoustic signal

sounds when the preset tor

que is reached and the machine then switches

off. You must release and press the ON/OFF

switch

[1-9]

again to start the machine.

8.4

Drilling

Adjust the switch

[1-7]

so that its marking

faces the drilling symbol

[1-5]

. Maximum tor

que is set in this position.

9

Tool holder, attachments

WARNING

Risk of injury

► Remove the battery pack from the power

tool before performing any work on the

power tool.

CAUTION

Risk of injury from hot and sharp tool

► Do not use any blunt or faulty tools.

► Wear protective gloves.

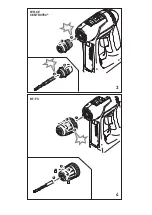

9.1

CENTROTEC tool chuck [4]

Quick change of tools with CENTROTEC shaft

Only clamp CENTROTEC tools in CEN

TROTEC tool chucks.

9.2

Chuck BF-FX

For clamping drill bits and bits with max. shaft

diameter of 13 mm.

Clamp tool centrally in the chuck.

9.3

Angle attachment DD-AS [6]

Drilling and screwing at right angle to machine

(partly as an accessory).

9.4

Eccentric attachment DD-ES [7]

Screwdriving near edges with bits according to

ISO 1173 (partly as accessory).

9.5

Tool holder in the drill spindle [8]

Bits can be inserted directly into the hexagon

socket holder of the drill spindle.

10 Working with the machine

WARNING

Risk of injury

► Always secure the workpiece in such a

manner that it cannot move while being

machined.

10.1 Bit depot [1-2]

Magnetic, for storing bits and bit holders.

10.2 Acoustic warning signals

Acoustic warning signals sound and the ma

chine switches off in the following operating

states:

English

15