9.5

After finishing work

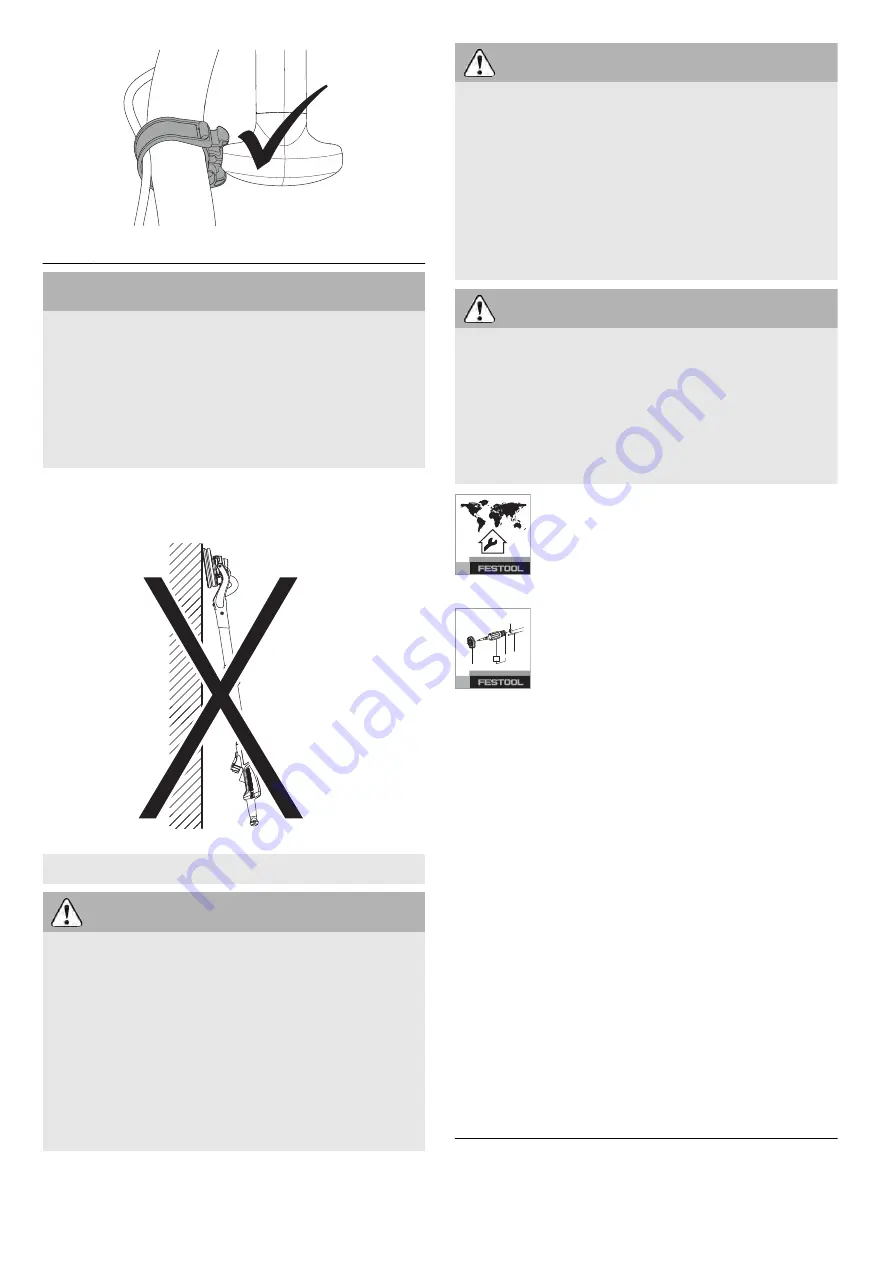

NOTICE

Damage and contamination of the power tool

► Do not set down the power tool on the

backing pad [1-18] or T-handle [1-6] -

[10].

► Always place the power tool on its side or

use the PLANEX tool holder on the mobile

dust extractor.

► Once you have finished the sanding work,

switch off the power tool and set it down.

10

10 Service and maintenance

WARNING

Any maintenance or repair work that re

quires opening of the motor or gear housing

should only be carried out by an authorised

Customer Service Centre (name supplied by

your dealer)!

► Maintenance or repair work carried out by

an unauthorised person can lead to the

wrong connection of the power cord or oth

er components, which in turn can lead to

accidents with serious consequences.

WARNING

To prevent accidents, always remove the

plug from the power supply socket before

carrying out any changes or maintenance

work on the tool!

► Do not use compressed air to clean the

electrical tool! Do not try to clean parts in

side the tool in this way, as you could let

foreign objects in through the openings of

the tool housing.

CAUTION

Certain cleaning agents and solvents are

harmful to plastic parts.

► Some of these include, but are not limited

to: Gasoline, Acetone, Methyl Ethyl Ketone

(MEK), Carbonyl Chloride, cleaning solu

tions containing Chlorine, Ammonia, and

household cleaners containing Ammonia.

Customer service and repairs must

only be carried out by the manufac

turer or service workshops. Find the

nearest address at:

www.festoolusa.com/service

Always use original Festool spare

parts. Order no. at:

www.festoolusa.com/service

EKAT

1

2

3

5

4

Check all warnings on the electric power tool

for readability and completeness. Replace

missing or illegible warnings.

–

Always state the serial number on the

name plate of the handle [1-1] when having

the tool serviced and repaired.

–

Check the plug and cable on a regular ba

sis and, if they are damaged, have them re

placed by an authorised customer service

workshop.

–

Do not clean the power tool with com

pressed air.

–

To ensure constant air circulation, always

keep the cooling air openings in the motor

housing clean and free of blockages.

–

Vacuum the backing pad regularly.

–

Keep all parts of the tool clean, especially

the controls and housing openings, and

clean them regularly with a brush.

10.1 Backing pad brake

The backing pad brake brushes off the backing

pad and prevents uncontrolled turning of the

English

18