9

2.2

To change the direction of rotati-

on

The selector button (1.4) determines the direc-

tion of rotation.

Turn button from right to left =

clockwise ro-

tation.

Turn button from left to right =

antic-

lockwise rotation.

Selector button in central

position =

circuit interlock.

2.3

Shifting speeds

Change only when completely stop-

ped!

Using the shift lever (1.5), the speed can be

changed.

1. Speed:

Lever forward - Figure 1 is visible.

2. Speed:

Lever backwards - Figure 2 is vi-

sible.

2.4

Torque adjustment

By turning the adjustment ring (1.6) the re-

quired torque can be adjusted. The arrow (1.7)

aligns with the adjusted state.

The machine switches off when the set torque

has been reached. The machine does not start

running again until the ON/OFF switch (1.3) is

released and then pressed again.

Drilling

Drilling symbol on adjustment ring aligns with

the arrow = maximum torque.

Screws

Torque corresponding to setting:

Position 1 = low torque

Position 20 = high torque

3

Tool holding fi xture, attachments

3.1

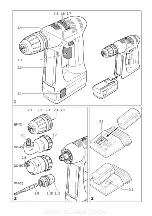

Chuck BF-FX

The chuck is used to clamp drills and bits.

a)

Fitting/removing the chuck

Fitting

-

Place the chuck on the drill spindle (2.5)

and twist until the hexagon key (2.4) of the

chuck latches into the hexagon socket of the

drill spindle.

-

Pull the unlocking ring (2.3) forwards,

press the chuck onto the drill spindle up to

the stop and release the unlocking ring.

Removal

- Pull the unlocking ring forwards and remove

the chuck.

b)

Changing tools

- Turn the clamping sleeve (2.2) anti-clockwise

to open the clamping jaws (2.1) (

Note:

the

spindle is automatically locked when the ma-

chine is switched off).

-

Insert the tool into the chuck.

- Clamp the tool by turning the clamping sleeve

clockwise. Always make sure that the tool is

clamped centrally in the chuck.

3.2

Angle attachment DD-AS

The angle attachment permits work (drilling,

screwing) vertical to the machine’s longitudinal

axis.

a)

Fitting/removing the angle attach-

ment

Fitting

- Place the angle attachment on the drill spindle

and turn until it catches in the desired position

(

Note:

The angle attachment can be fi tted in

16 different angle settings).

- Lock the angle attachment by turning the

fastening ring (2.7) tightly clockwise.

Removal

- Turn the fastening ring anti-clockwise up to

the stop and remove the angel attachment.

b)

Fitting/removal of chuck on angle

attachment

The chuck is fi tted on the shaft (2.6) of the

angle attachment in the same way as on the

drill spindle of the machine.

3.3

Eccentric attachment DD-ES

The eccentric attachment is used to hold bits.

It allows screwing close to edges.

a)

Fitting/removing the eccentric at-

tachment

The eccentric attachment is fi tted/removed in

the same was as the angle attachment (see

Chapter 3.2).

b)

Changing tools

- Pull the unlocking ring (2.8) back and remove

the tool and/or insert the new tool.

3.4 CENTROTEC

WH-CE

toolholder

The CENTROTEC toolholder enables rapid chan-

ges of tools with CENTROTEC shafts.

Do

not

fi t CENTROTEC tools at the round

shaft section in a conventional chuck to

prevent damage to the shaft.

Danger of injury!

When changing

tools, handle the tool and its sharp

cutters with special care and wear pro-

tective gloves, if necessary.

a) Fitting/removing

CENTROTEC

Fitting

- Pull the release ring (2.11) forwards, place

the toolholder as far as it will go on the drill

spindle (2.5) and let go of the release ring.

Removal

- Pull the release ring forwards and take off the

toolholder.

b) Changing

tools

- To insert or remove a tool with CENTROTEC

shaft, pull the green release ring (2.10) back.

On inserting the tool, turn it until its hex shank

arbour (2.9) locks in place in the hexagonal

shank of the drill spindle, and push the tool

into the toolholder as far as it will go.

3.5

Tool holding fixture in the drill

spindle

Bits can be fi tted directly in the hexagon socket

holder of the drill spindle (2.5) to make the

machine lighter and shorter.

Seen at Ideal Tools.

Summary of Contents for C 12

Page 3: ...Seen at Ideal Tools ...