up, if it is not possible to regulate the speed

and in the event of generation of smoke or

the smell of burning from the machine.

–

Wear suitable personal protective equip

ment: Ear protection, safety goggles, a dust

mask for work that generates dust.

–

Only for AS/NZS: The tool shall always be

supplied via residual current device with a

rated residual current of 30 mA or less.

2.3

Router safety instructions

General

–

Proceed with extreme care when unpack

ing, packing and handling the tool (e.g. in

stalling it in the machine). There is a risk of

injury from extremely sharp cutting edges!

–

When handling the tool, wearing safety

gloves provides a more secure hold of the

tool and further reduces the risk of injury.

–

Observe the safety warnings for your ma

chine.

–

Comply with the safety regulations that ap

ply in your country.

–

WARNING! Do not use tools with visible

cracks or blunt or damaged cutting edges.

Installation and mounting

–

Tools must be clamped in such a way that

they cannot come loose during operation.

–

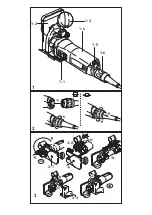

Insert the routing tool into the collet as far

as possible or at least up to the mark on

the router shank.

–

When assembling the tool, it must be en

sured that the clamping takes place in the

routing machine's collet and that the edges

do not come into contact with one another

or the fixed clamps.

–

Clamping or fixing nuts must be tightened

using suitable keys, etc. and with the tor

que specified by the manufacturer.

–

Do not lengthen the key or tighten by hitting

with a hammer.

–

The clamping surfaces must be cleaned to

remove contamination, grease, oil and wa

ter.

–

Clamping screws must be tightened ac

cording to the manufacturer's instructions.

Service and maintenance

–

Always use original Festool spare parts.

–

Repairs and sanding work may only be car

ried out by experts.

–

The tool design must not be changed.

–

For repairs and sanding work, see the addi

tional instructions at www.festool.com.

–

Deresinify and clean the tool regularly

(cleaning agent with pH between 4.5 and 8).

–

Blunt edges can be resharpened on the

clamping surface to a minimum cutting

edge thickness of 1 mm.

–

Only transport the tool in suitable packag

ing – risk of injury!

2.4

Emission levels

The levels determined in accordance

with EN 62841 are typically:

Sound pressure level

L

PA

= 81 dB(A)

Sound power level

L

WA

= 92 dB(A)

Uncertainty

K = 1,5 dB

CAUTION

Noise generated when working

Risk of damage to hearing

► Use ear protection.

Vibration emission level a

h

(vector sum for

three directions) and uncertainty K measured in

accordance with EN 62841:

Auxiliary handle

a

h

< 2,5 m/s

2

K = 1,5 m/s

2

The specified emission levels (vibration, noise)

–

are used to compare machines.

–

They are also used for making preliminary

estimates regarding vibration and noise

load during operation.

–

They represent the primary applications of

the power tool.

CAUTION

The emission values may deviate from the

specified values. This is dependent on how

the tool is used and the type of workpiece

being machined.

► The actual load during the entire operating

cycle must be evaluated.

► Depending on the actual load, suitable pro

tective measures must be defined in order

to protect the operator.

3

Intended use

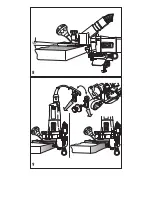

The edge router is designed for flush trimming

and profile routing wood, plastic and similar

materials.

English

14

Summary of Contents for OFK 700 EQ

Page 2: ......

Page 3: ...3 2 3 1 3 3 3 3A 3B 1 1 1 1 4 1 3 1 6 1 2 1 5 2 ...

Page 4: ...SW 19 4 2 4 1 4 3 180 4 5 6 7 2 7 1 7 3 7 ...

Page 5: ...9 8 1 5 ...