8

6.1

Rough speeds for work with diffe-

rent materials

a)

Polishing

Work

Setting

Distribute polish

1-2

Polishing sensitive surfaces

(e.g. painted plastic parts)

3-4

High-gloss polishing

5-6

b)

Sanding

Work

Setting

Light sanding of thin topcoats

4-6

Sanding smearing paints / varnishes

4-6

Sanding off dry, cracked paint

6

Removing anti-fouling paint

6

Sanding out rust on varnished metal parts (6)

Sanding thermoplastics

2-4

Sanding wood

6

Smoothing stained wood with

sanding brush

2-4

Cleaning sandstone, concrete,

shuttering material

4-6

( ) Only conditionally suitable

7

AH-RAS 115 extractor hood

7.1

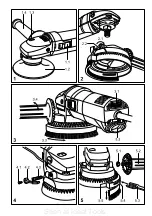

Fitting (Fig. 2)

Before fitting the hood, take care to

ensure that the clamping lever is in the

released position (2.2).

Press the extractor hood firmly onto the

clamping neck of the rotary polisher and fa-

sten by pushing the clamping lever forwards

(2.1).

Do not start work if the hood extractor

hood is not safely and firmly locked

onto the clamping neck.

If the clamping force should deteriorate after

frequent use, adjust the clamping lever:

loosen screw (4.1) on clamping lever and

remove clamping lever (4.2),

tighten square-head threaded bolt (4.3) by

hand,

replace clamping lever and fasten with screw.

The optimum position can be determined by

closing the clamping lever before tightening

the screw.

7.2

Changing the position of the

rotating handle

The rotating additional handle can be also be

fastened on the right of the extractor hood

depending on the users personal preferences.

It should be exchanged with the clamping lever.

Loosen screw (4.1) on clamping lever and

remove clamping lever (4.2).

Remove square-head threaded bolt (4.3).

Loosen additional handle (5.2) with Allen key,

size 6.

The clamping lever and additional handle can

now be exchanged. Reassemble in reverse

order.

You can adjust the free-running of the rotating

additional handle using the counternut (5.1)

by clamping this against the hood with an open-

end spanner, size 13, before tightening the ad-

ditional handle.

7.3

Changing the brush insert

Press the brush insert out by inserting a

screwdriver into the square hole (5.5).

Place the new brush insert into the groove,

adjust the radius by bending slightly and push

in firmly until the insert rests on the base of

the hood.

The bevel of the bristles must hereby point

outwards.

Two different brush inserts are available:

AH-RAS D 115 Poly (Order No. 484 727),

contains 2 polyamide brushes (as

replacements for worn brushes).

AH-RAS D 115 Metal (Order No. 484 728),

contains 1 metal brush (for use on materials

which produce sparks).

7.4

Changing the sanding pad

In normal cases the sanding pad (1.2) can be

unscrewed from the working spindle by hand

after the spindle stop (1.3) has been pressed.

However, should the sanding pad sit firmly

Remove brush insert

Insert special key (5.3) through slot (5.4)

into the tools key slot.

Press the spindle stop and loosen the tool by

turning the special key.

Always screw the sanding pad onto the

working spindle by hand.

This greatly facilitates a later loosening.

7.5

Sanding and dust extraction

Connect the hose (Ø 27 mm) of a

Festool dust extractor to the adapter

(3.2) on the rear of the rotary

polishers casing.

The brush (3.3) can be adjusted with the

rotating handle (3.4).

This permits an optimum adjustment to the

respective working position.

Always rotate the brush in the direction of flight

of the sanding dust.

When sanding metals and other

materials which produce sparks, a

spark trap (Order No. 484 733) must

be fitted between the dust extractor

and rotary polisher for safety reasons.

Seen at Ideal Tools.

Summary of Contents for RAP 80.02 E

Page 3: ...Seen at Ideal Tools...