9

8

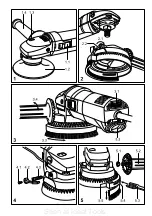

Fitting tools

Do not use tools whose maximum

permissible speed is lower than the

speed specified on the rotary polishers

ratings plate.

This is guaranteed with all original accessories

from Festool.

There are two types of fixtures depending on

the tools used.

The motor spindle is locked by pressing the

spindle stop (1.3). This permits a fast and easy

replacement of the tools used.

8.1

Direct fitting

The sanding pad STF D80 included with the

tool and the polishing drum available as an

accessory, together with the individual sanding

disks, all have an M14 thread.

These can be screwed directly into the working

spindle.

8.2

Fitting with locking nut

The flexible sanding pad is fastened to the drive

shaft with a locking nut and tightened with the

face spanner.

9

Additional handle

The additional handle (1.4) can be optionally

fitted on the right or left of the rotary polishers

transmission head.

10

PoliStick and Stickfix System

All PoliStick felts are mounted on the STF D80

polishing pad.

Stickfix sanding discs D115 are fastened on

the Stickfix sanding pad STF D115.

Only use polishing and sanding pads

with undamaged Stickfix adhesive

covering.

Check before use whether the hook-eye

fastening has been damaged by incorrect use

(e.g. melted).

11

Accessories

The accessory order number can be found in

your Festool catalogue or on the Internet under

www.festool.com".

12

Care and maintenance

Always disconnect the machine at

its mains plug before performing

maintenance work!

Keep the ventilation slots in the motor housing

clean and free of obstructions at all times to

ensure an adequate circulation of air.

The tool is fitted with special motor brushes

with an automatic cut-out.

When the brushes become worn the power

supply is shut off automatically and the polisher

comes to a standstill.

Any maintenance and repair work

requiring an opening of the motor

housing may only be carried out by an

authorised customer service

workshop.

13

Warranty

Our equipment is under warranty for at least

12 months with regard to material or

production faults in accordance with national

legislation.

In the EU countries, the warranty period is 24

months (an invoice or delivery note is required

as proof of purchase).

Damage resulting from, in particular, normal

wear and tear, overloading, improper handling,

or caused by the user or other damage caused

by not following the operating instructions, or

any fault acknowledged at the time of

purchase, is not covered by the warranty.

Complaints will only be acknowledged if the

equipment has not been dismantled before

being sent back to the suppliers or to an

authorised Festool customer support

workshop.

Store the operating instructions, safety notes,

spare parts list and proof of purchase in a safe

place.

In addition, the manufacturers current

warranty conditions apply.

Note

We reserve the right to make changes to the

technical data contained in this information as

a result of ongoing research and development

work.

Seen at Ideal Tools.

Summary of Contents for RAP 80.02 E

Page 3: ...Seen at Ideal Tools...