15

Vibration emission value a

h

(vector sum for three

directions) and uncertainty K measured in accord-

ance with EN 60745:

Sanding: a

h

= 3.5 m/s

2

K = 2.0 m/s

2

The specifi ed emissions values (vibration, noise)

– are used to compare machines.

– They are also used for making preliminary es-

timates regarding vibration and noise loads

during operation.

– They represent the primary applications of the

power tool.

Increase possible for other applications, with oth-

er insertion tools or if not maintained adequately.

Take note of idling and downtimes of machine!

6 Commissioning

WARNING

Risk of accident if the machine is operated using

unauthorised voltages or frequencies.

- The mains voltage and the frequency of the

power source must correspond with the spe-

cifi cations on the machine’s name plate.

- In North America, only Festool machines with

a voltage specifi cation of 120 V/60 Hz may be

used.

The tool is fi tted with an on/off switch [1-1] with

switch-on lock [1-2]. Press the switch-on lock

to release the switch. Pressing and holding the

switch-on lock briefl y after the machine starts

locks the switch while the motor is running. The

motor switches off when you press the on/off

switch again.

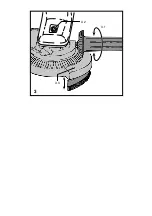

Attaching the additional handle

The additional handle (1-5) can be secured on ei-

ther the right or left side of the gear head on the

rotary sander.

Attaching extraction hood AH-RAS D 180

The extraction hood can only be used in combina-

tion with sanding pads STF D 180 and 2F D 180.

Remove the two Allen screws [2-1 and 2-6] from

the bearing cover on the machine fi rst of all.

Push the extraction hood onto the machine

fl ange and secure the hood with the two Allen

screws [2-2].

7 Machine

settings

WARNING

Risk of accident, electric shock

Always pull the plug out of the socket before

performing any type of work on the machine.

7.1 Electronics

The machine features full-wave electronics with

the following features:

Smooth start-up

The electronically controlled smooth start-up en-

sures that the machine starts up jolt-free.

Speed control

You can regulate the rotational speed steplessly

between 800 and 4200 rpm using the adjusting

wheel [1-4].

The following table serves as a guideline to help

you select the best electronics setting for the work-

ing material. The transition between each speed

setting is smooth.

Processed material

Working procedure

Electronics

setting

Sanding off dry,

cracked paint

6

Sanding paint that "smears"

2 - 4

Sanding thin layers of varnish

3 - 5

Removing anti-fouling coats

3 - 6

Sanding hard GRP parts

4 - 6

Sanding thermoplastics

2 - 3

Sanding wood

6

Cleaning sandstone, concrete,

shuttering material

4

Removing rust from painted

metal parts

(6)

( ) = suitable to a limited extent

Constant speed

The preselected motor speed remains constant

through electronic control. This ensures a uniform

cutting speed even when under strain.

Overload safety device

In extreme applications, the current consumption

may far exceed the permitted nominal value. A

"safety coupling" integrated in an electronic over-

load safety device switches off the motor and pre-

vents it from burning out. Motor operation resumes

immediately after the load is relieved.