AUTORAKE

®

OPERATION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE

®

OPERATION

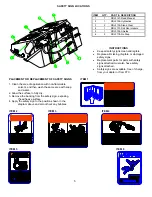

WARNING

Failure to obey the following procedures could result in death or serious injury.

•

Never lift this product above (a.) the operator’s eye level or (b.) to a height where visibility is

obstructed, whichever is lower.

•

Do not roll back this product so far that the load falls off toward or on the operator.

•

Do not lock the auxiliary hydraulics of your power unit in the “ON” position.

•

feet away from the unit when operating.

CAUTION

Failure to obey the following procedures may result in personal injury.

•

of this product as a step. Under certain conditions, this area can be slippery.

IMPORTANT

Attempting to pick up large rocks, large tree branches, etc.

CAN result in damage to this product and

WILL void all FFC warranties.

IMPORTANT

Using this product to till compacted soil

CAN result in damage to this product and

WILL void all FFC warranties.

Before using this product on an area, make sure that:

•

the area is free of all boulders larger than 6” in diameter, all logs and large tree branches, all wire, all lumber, and any

other item that is too large for the bucket or could get wrapped around the rake chain, and

•

the soil is relatively loose and any compacted areas have been tilled with another piece of equipment to a depth of 2”

or deeper.

RAKING

Keeping in mind that

all raking must be done while moving backward

, position your power unit and this product on the

area to be raked. To begin raking:

1. activate the auxiliary hydraulics for operating

the

rake

chain,

(If the rake chain does not move but the hydraulic cylinder begins to retract, then activate the auxiliary hydraulics

in the opposite direction to get the rake chain to operate.)

2. lower the loader arms completely and set the loader arm control in the float position,

3. tilt this product forward until the weight of the rake portion is resting on the depth adjustment plates, and

4. move your power unit slowly backward.

To achieve the best possible results, please keep in mind that:

•

If the rake is throwing too much soil into the bucket, then the depth adjustment plates should be placed in a lower hole

on the main housing.

•

If the rake is slipping over items that should be collected, then the depth adjustment plates should be placed in a

higher hole on the main housing.

•

Multiple passes may be needed to achieve the desired results depending on what those results are and what the

initial conditions are.

•

The wide variety of soil types, moisture conditions, compaction levels, foliage densities, and rock and debris

quantities that can be encountered mean that the operator may need to make adjustments based upon the operator’s

experience.

IMPORTANT

Opening the main housing and using the bucket for standard bucket operations

CAN result in damage to this product and

WILL void all FFC warranties.

7

Summary of Contents for AUTORAKE LAF6866

Page 11: ...PARTS ILLUSTRATION 10...