FGE Elettronica S.p.a

Via C.A. Dalla Chiesa, 10

25017 – Lonato del Garda (BS)

P.I. IT01975940162

Tel: 030 9919700

Fax: 030 9913955

info@fgespa.com

www.fgespa.com

EN

SLM1: Quick Reference – Rev06

Page 4/9

2.2

Preliminary checks on panels

The installation of the automation system must be done by technically competent personnel only, meeting

the professional requirements provided by the legislation in force in the country of installation.

Before starting with the installation of the automation system:

-

Check that the structure that has to be automated is stable and sturdy to support the weight of the

automation system. If these conditions are not verified, do not proceed with the installation.

-

Make sure that the power patch cord has been prepared near the automation system.

-

Verify that the movement of the panels is free and without obstacles along the entire travel.

2.3

Installation of mechanical and electronic parts

1.

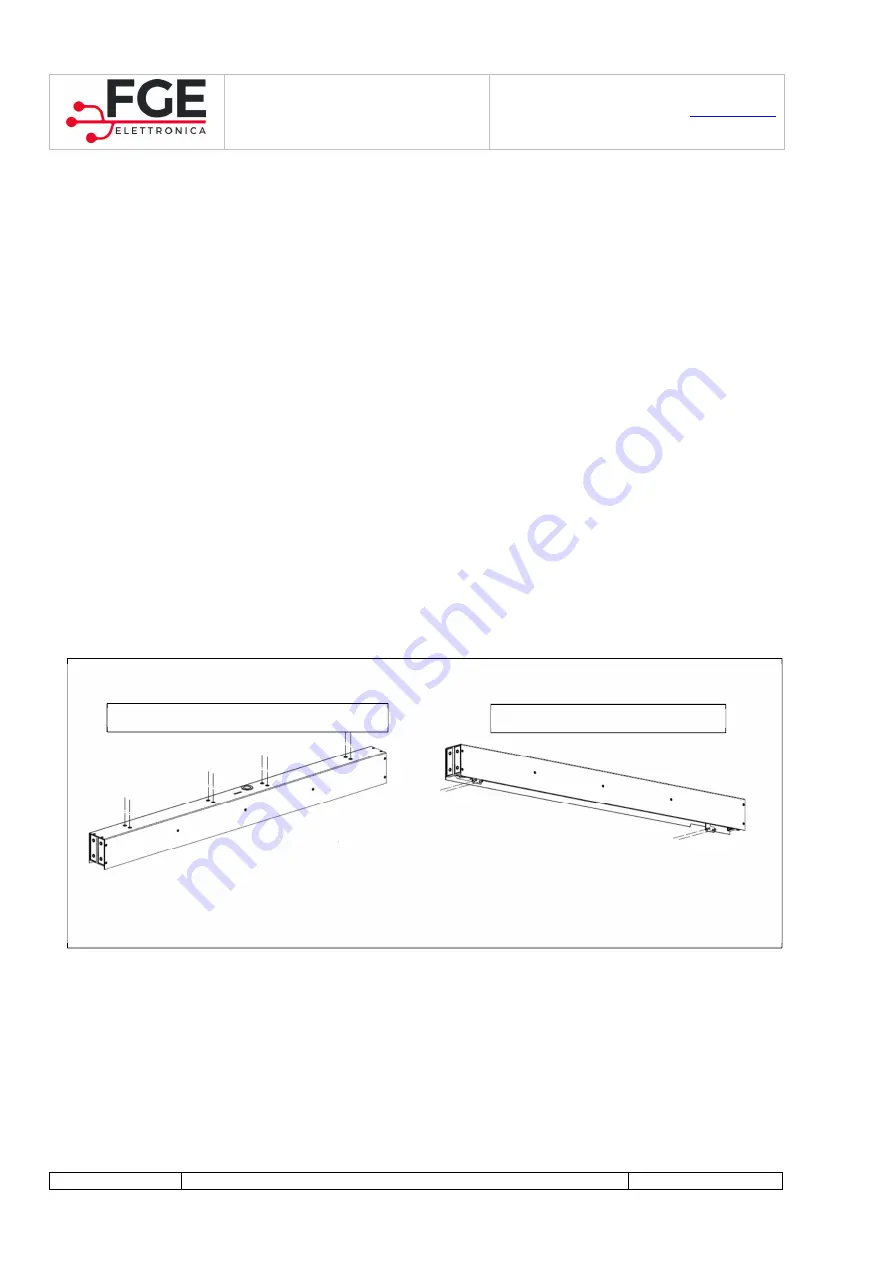

Mechanical installation of the header

a.

Fasten the header to the support frame, as shown in Figure 2-1

2.

Fasten the panel to the header, as shown in Figure 2-1

3.

Mechanical installation of the control unit (and concentrator, if present) in a predefined and easily

accessible place.

Figure 2-1. Scheme of the mechanical installation of the header

Once the installation of mechanical parts is completed and the panels have been fasten to the headers,

verify carefully that the movement of the panels is smooth and without obstacles.

Once the mechanical mounting is finished and the Control unit and the Concentrator (if present) have been

fastened near the headers, proceed as indicated in the table on the following page.

M4 screws for panels fixation

Bushings M6 for fastening to the refrigerator

Summary of Contents for SLM1

Page 19: ...NOTE ...

Page 20: ...NOTE ...